Graphene antibacterial modified plastic film for medicine packaging and preparation method

A technology for graphene and packaging, which is applied in the field of graphene antibacterial modified plastic film and preparation for pharmaceutical packaging, which can solve the problems of poor antibacterial performance and barrier performance, and achieve the goal of improving barrier performance, promoting uniform dispersion, and improving antibacterial performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

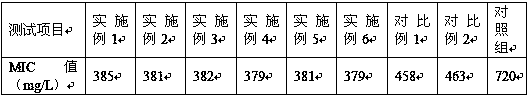

Examples

Embodiment 1

[0026] A preparation of graphene antibacterial modified plastic film for pharmaceutical packaging, comprising the following steps:

[0027] S1. Add graphene oxide dispersion liquid and silver-based zeolite antibacterial agent to chitosan acetic acid solution, stir to make chitosan surface groups react with graphene oxide surface groups to closely combine, then add plasticizer The prolamin solution is mixed, ultrasonically dispersed, and stirred to obtain a mixed film-forming liquid; wherein the mass ratio of chitosan acetic acid solution, graphene oxide dispersion, silver-based zeolite antibacterial agent, and plasticizer-containing prolamin solution is 30:15:8:1; the mass concentration of plasticizer in the gliadin solution containing plasticizer is 3%, and the plasticizer is oleic acid; the stirring speed is 450r / min, and the stirring time is 60min ;

[0028] S2. Put the mixed film-forming solution obtained in step S1 into a spray bottle, add a reducing agent to reduce grap...

Embodiment 2

[0031] A preparation of graphene antibacterial modified plastic film for pharmaceutical packaging, comprising the following steps:

[0032] S1. Add graphene oxide dispersion liquid and silver-based zeolite antibacterial agent to chitosan acetic acid solution, stir to make chitosan surface groups react with graphene oxide surface groups to closely combine, then add plasticizer The prolamin solution is mixed, ultrasonically dispersed, and stirred to obtain a mixed film-forming liquid; wherein the mass ratio of chitosan acetic acid solution, graphene oxide dispersion, silver-based zeolite antibacterial agent, and plasticizer-containing prolamin solution is 40:12:9:0.8; the mass concentration of plasticizer in the prolamin solution containing plasticizer is 5%, and the plasticizer is polyethylene glycol; stirring speed is 550r / min, stirring time 30min;

[0033] S2. Put the mixed film-forming solution obtained in step S1 into a spray bottle, add a reducing agent to reduce graphene...

Embodiment 3

[0036] A preparation of graphene antibacterial modified plastic film for pharmaceutical packaging, comprising the following steps:

[0037] S1. Add graphene oxide dispersion liquid and silver-based zeolite antibacterial agent to chitosan acetic acid solution, stir to make chitosan surface groups react with graphene oxide surface groups to closely combine, then add plasticizer The prolamin solution is mixed, ultrasonically dispersed, and stirred to obtain a mixed film-forming liquid; wherein the mass ratio of chitosan acetic acid solution, graphene oxide dispersion, silver-based zeolite antibacterial agent, and plasticizer-containing prolamin solution is 25:20:6:1.5; The mass concentration of plasticizer in the gliadin solution containing plasticizer is 1.5%, and described plasticizer is stearic acid; Stirring speed is 380r / min, and stirring time is 45min;

[0038] S2. Put the mixed film-forming solution obtained in step S1 into a spray bottle, add a reducing agent to reduce g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com