Heat-resistant archaistic iron coarse pottery and preparation method thereof

An iron-based, heat-resistant technology, applied in the production and application of clay products and ceramic materials, can solve problems such as increasing production costs and losing ceramic properties, and achieves improved thermal shock resistance, reduced expansion coefficient, and increased mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

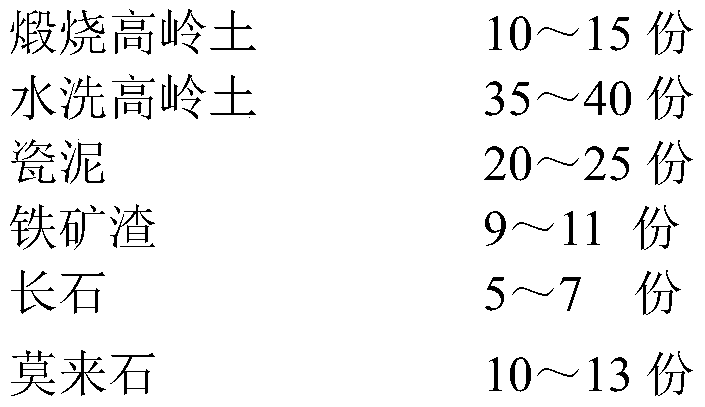

[0031] Components and content in the formula of the present invention are:

[0032]

[0033] Accurately formulate the weight of each raw material in the above formula, make mud sticks, form green bodies, or carve patterns on the green bodies according to the mud making method above. Or add color patterns, put them in a kiln and burn them with reduced flames. During the firing cycle in a reducing atmosphere, the carbon monoxide gas content (volume fraction) is kept at 3% to 4%; the flame transfer temperature is 950°C to ensure that the porcelain body becomes iron-like black brown; the high fire holding temperature is 1270°C to 1290°C °C, the holding time is 10 minutes; the annealing holding temperature is 1020 °C, and the holding time is 45 minutes. The volume expansion coefficient is 100.5×10 -7 / °C. The water absorption test and thermal stability test of the obtained antique irony black brown cooking stoneware products are as follows:

[0034] Water absorption test:

...

Embodiment 2

[0039]Components and content in the formula of the present invention are:

[0040]

[0041]

[0042] Accurately formulate the weight of each raw material in the above formula, make mud sticks, form green bodies, or carve patterns on the green bodies according to the mud making method above. Or add color patterns, put them in a kiln and burn them with reduced flames. During the firing cycle in a reducing atmosphere, the carbon monoxide gas content (volume fraction) is kept at 3% to 4%; the flame transfer temperature is 950°C to ensure that the porcelain body becomes iron-like black brown; the high fire holding temperature is 1270°C to 1290°C °C, the holding time is 10 minutes; the annealing holding temperature is 1020 °C, and the holding time is 45 minutes. The volume expansion coefficient is 94.6×10 -7 / °C. The water absorption test and thermal stability test of the obtained antique irony black brown cooking stoneware products are as follows:

[0043] Water absorptio...

Embodiment 3

[0048] Components and content in the formula of the present invention are:

[0049]

[0050] Accurately formulate the weight of each raw material in the above formula, make mud sticks, form green bodies, or carve patterns on the green bodies according to the mud making method above. Or add color patterns, put them in a kiln and burn them with reduced flames. During the firing cycle in a reducing atmosphere, the carbon monoxide gas content (volume fraction) is kept at 3% to 4%; the flame transfer temperature is 950°C to ensure that the porcelain body becomes iron-like black brown; the high fire holding temperature is 1270°C to 1290°C °C, the holding time is 10 minutes; the annealing holding temperature is 1020 °C, and the holding time is 45 minutes. The volume expansion coefficient is 91.8×10 -7 / °C. The water absorption test and thermal stability test of the obtained antique irony black brown cooking stoneware products are as follows:

[0051] Water absorption test:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com