Autonomous self-repairing elastomer with high tensile property as well as preparation method and application thereof

A tensile performance and self-repairing technology, which is applied in the measurement of the properties and forces of piezoelectric devices, can solve the problems of weak mechanical strength, long repair time, and low repair efficiency, and achieve high tensile performance and strong mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

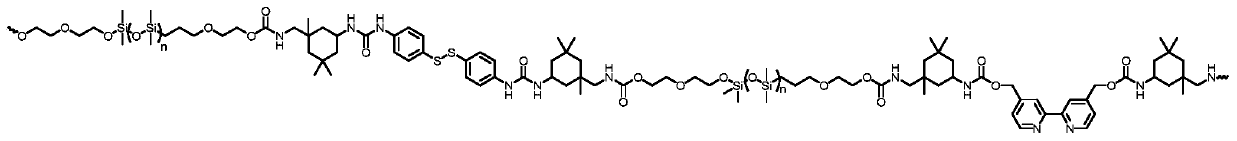

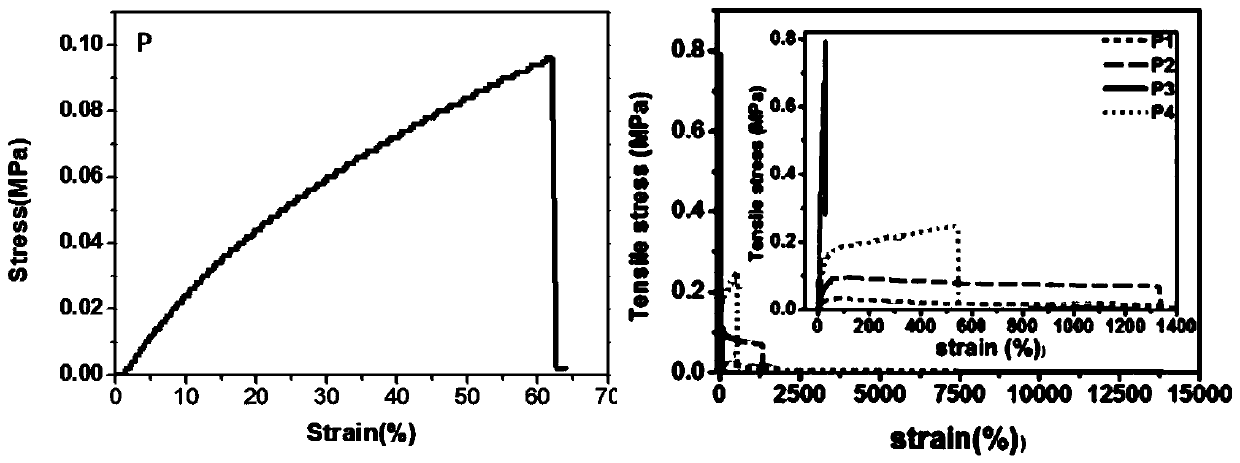

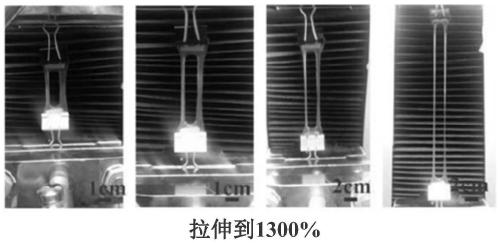

[0037] (1) Put 4.6g of double-terminated hydroxyl polydimethylsiloxane (HO-PDMS-OH) in a dry container, stir at 100°C for 1 hour under vacuum to remove moisture, and then cool down to 70°C.

[0038] (2), 0.25g of isophorone diisocyanate (IPDI) and 0.02g of dibutyltin dilaurate (DBTDL) were dissolved in DMAC and added dropwise to the reaction vessel, and stirred at 70°C for 3 hours under nitrogen to synthesize the prepolymer things.

[0039] (3), 0.06g 4,4'-dithiodianiline and 0.14g 2,2'-bipyridine-4,4'-dicarboxylic acid were dissolved in DMAC and added dropwise to the prepolymer in the reaction vessel In, stirred at 70°C for 3 hours to obtain the reaction product.

[0040] (4) Pour the reacted product into a polytetrafluoroethylene mold, and vacuum-dry at 90° C. for 12 hours to obtain the elastomer P1.

[0041] (5) The molar ratio of silicone resin Psi to weak hydrogen bond compound IP, disulfide bond monomer SS, and strong hydrogen bond compound BNB is 4:8:1:3.

Embodiment 2

[0043] (1) Put 4.60 g of double-terminated hydroxyl polydimethylsiloxane (HO-PDMS-OH) in a dry container, stir at 100°C for 1 hour under vacuum to remove moisture, and then cool down to 70°C.

[0044] (2), 0.25g of isophorone diisocyanate (IPDI) and 0.02g of dibutyltin dilaurate (DBTDL) were dissolved in DMAC and added dropwise to the reaction vessel, and stirred at 70°C for 3 hours under nitrogen to synthesize the prepolymer things.

[0045] (3) Dissolve 0.12g of 4,4'-dithiodianiline and 0.10g of 2,2'-bipyridine-4,4'-dicarboxylic acid in DMAC and add dropwise to the prepolymer in the reaction vessel In, stirred at 70°C for 3 hours to obtain the reaction product.

[0046] (4) Pour the reacted product into a polytetrafluoroethylene mold, and vacuum-dry at 90° C. for 12 hours to obtain the elastomer P2.

[0047] (5) The molar ratio of silicone resin Psi to weak hydrogen bond compound IP, disulfide bond monomer SS, and strong hydrogen bond compound BNB is 2:4:1:1.

Embodiment 3

[0049] (1) Put 4.60 g of double-terminated hydroxyl polydimethylsiloxane (HO-PDMS-OH) in a dry container, stir at 100°C for 1 hour under vacuum to remove moisture, and then cool down to 70°C.

[0050] (2), 0.50g of isophorone diisocyanate (IPDI) and 0.02g of dibutyltin dilaurate (DBTDL) were dissolved in DMAC and added dropwise to the reaction vessel, and stirred at 70°C for 3 hours under nitrogen to synthesize prepolymer things.

[0051] (3) Dissolve 0.48g of 4,4'-dithiodianiline and 0.19g of 2,2'-bipyridine-4,4'-dicarboxylic acid in DMAC and add dropwise to the prepolymer in the reaction vessel In, stirred at 70°C for 3 hours to obtain the reaction product.

[0052] (4) Pour the reacted product into a polytetrafluoroethylene mold, and vacuum dry at 90° C. for 12 hours to obtain the elastomer P3.

[0053] (5) The molar ratio of silicone resin PSi to weak hydrogen bond compound IP, disulfide bond monomer SS, and strong hydrogen bond compound BNB is 1:4:2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com