Preparation method and application of zif-8 modified cellulose membrane with switchable surface wettability

A ZIF-8, a technology for modifying cellulose, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve problems such as toxic solvents and ions, limit the application of oily wastewater, and monotonous wettability of membranes, and achieve the preparation method. Simple and easy to implement, good recyclability, good throughput effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of RC@PDA: Immerse the RC membrane in 100 mL of tris-HCl solution with a concentration of 9 mM, add 190 mg of dopamine, shake at 24 °C for 5 h, ultrasonically clean, and dry naturally to obtain RC@PDA membrane;

[0032] (2) 0.2945g of Zn(NO 3 ) 2 ·6H 2 O is mixed with 20mL of methanol solution to obtain mixed solution A; then 0.1642g of dimethylimidazole and 20mL of methanol solution are mixed to obtain mixed solution B; the RC@PDA membrane prepared in step (1) is immersed in mixed solution A After soaking for 25 minutes, add mixed solution B, the volume ratio of mixed solution A to mixed solution B is 1:1; stand at 24°C for 50 minutes, remove the product and wash it with methanol, and dry it in vacuum at 80°C for 11 hours to obtain ZIF-8 The modified cellulose membrane is RC@PDA / ZIF-8 membrane.

Embodiment 2

[0034] (1) Preparation of RC@PDA: Immerse the RC membrane in 100 mL of tris-HCl solution with a concentration of 10 mM, add 200 mg of dopamine, shake at 25 °C for 6 h, ultrasonically clean, and dry naturally to obtain RC@PDA membrane;

[0035] (2) 0.5870g of Zn(NO 3 ) 2 ·6H 2 O was mixed with 20mL of methanol solution to obtain mixed solution A; then 0.3284g of dimethylimidazole was mixed with 20mL of methanol solution to obtain mixed solution B; the RC@PDA membrane prepared in step (1) was immersed in mixed solution A After soaking for 30 minutes, add mixed solution B, the volume ratio of mixed solution A to mixed solution B is 1:1; stand at 25°C for 60 minutes, remove the product, wash it with methanol, and dry it under vacuum at 80°C for 12 hours to obtain ZIF-8 modification The cellulose membrane is RC@PDA / ZIF-8 membrane.

Embodiment 3

[0037] (1) Preparation of RC@PDA: Immerse the RC membrane in 100 mL of tris-HCl solution with a concentration of 11 mM, then add 210 mg of dopamine, shake it at 26°C for 7 hours, clean it ultrasonically, and dry it naturally to obtain RC@PDA membrane;

[0038] (2) 1.1780g of Zn(NO 3 ) 2·6H 2 O was mixed with 20mL of methanol solution to obtain mixed solution A; then 0.6568g of dimethylimidazole was mixed with 20mL of methanol solution to obtain mixed solution B; the RC@PDA membrane prepared in step (1) was immersed in mixed solution A After soaking for 35 minutes, add mixed solution B, the volume ratio of mixed solution A to mixed solution B is 1:1; stand at 26°C for 70 minutes, remove the product and wash it with methanol, and dry it under vacuum at 80°C for 13 hours to obtain ZIF-8 modification The cellulose film is RC@PDA / ZIF-8 film.

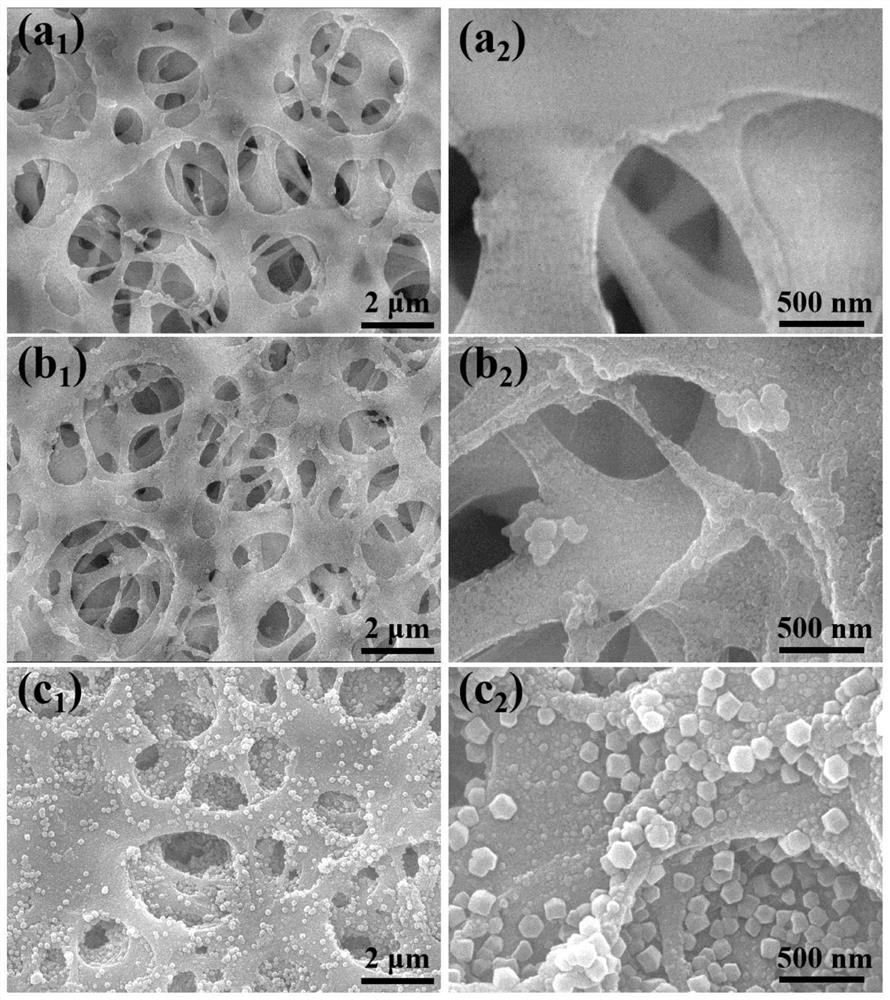

[0039] figure 1 SEM images of RC(a), RC@PDA(b) and RC@PDA / ZIF-8(c) films. The pristine RC membrane shows a laminated porous structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| separation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com