Method for growing large-size perovskite single crystal by using ternary mixed solvent

A mixed solvent and perovskite technology, applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve problems such as difficulty in single crystal growth, and achieve the effects of controllable growth method, expansion of light absorption range, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Lead bromide (PbBr 2 ) and cesium bromide (CsBr) were mixed and dissolved in DMSO at a molar ratio of 1:1 to obtain a mixed solution with a concentration of 0.4 mol / L. After the solution was fully stirred evenly at 40°C, two solvents, DMF and GBL, were added dropwise. The volume ratio of the three solvents was DMSO:DMF:GBL=5:1:1, and the precursor solution dissolved in the ternary mixed solvent was obtained. . After the solution was sealed, it was transferred to a crystal growth tank, and the temperature was raised to 90° C. to start crystal growth. Through spontaneous crystallization, large-sized CsPbBr is finally obtained 3 Perovskite single crystal, the single crystal size is about 2mm, the ultraviolet absorption edge is located at 560nm, and the optical band gap is 2.3eV.

[0045] figure 1 Obtaining CsPbBr for Example 1 3 Physical photos of single crystals;

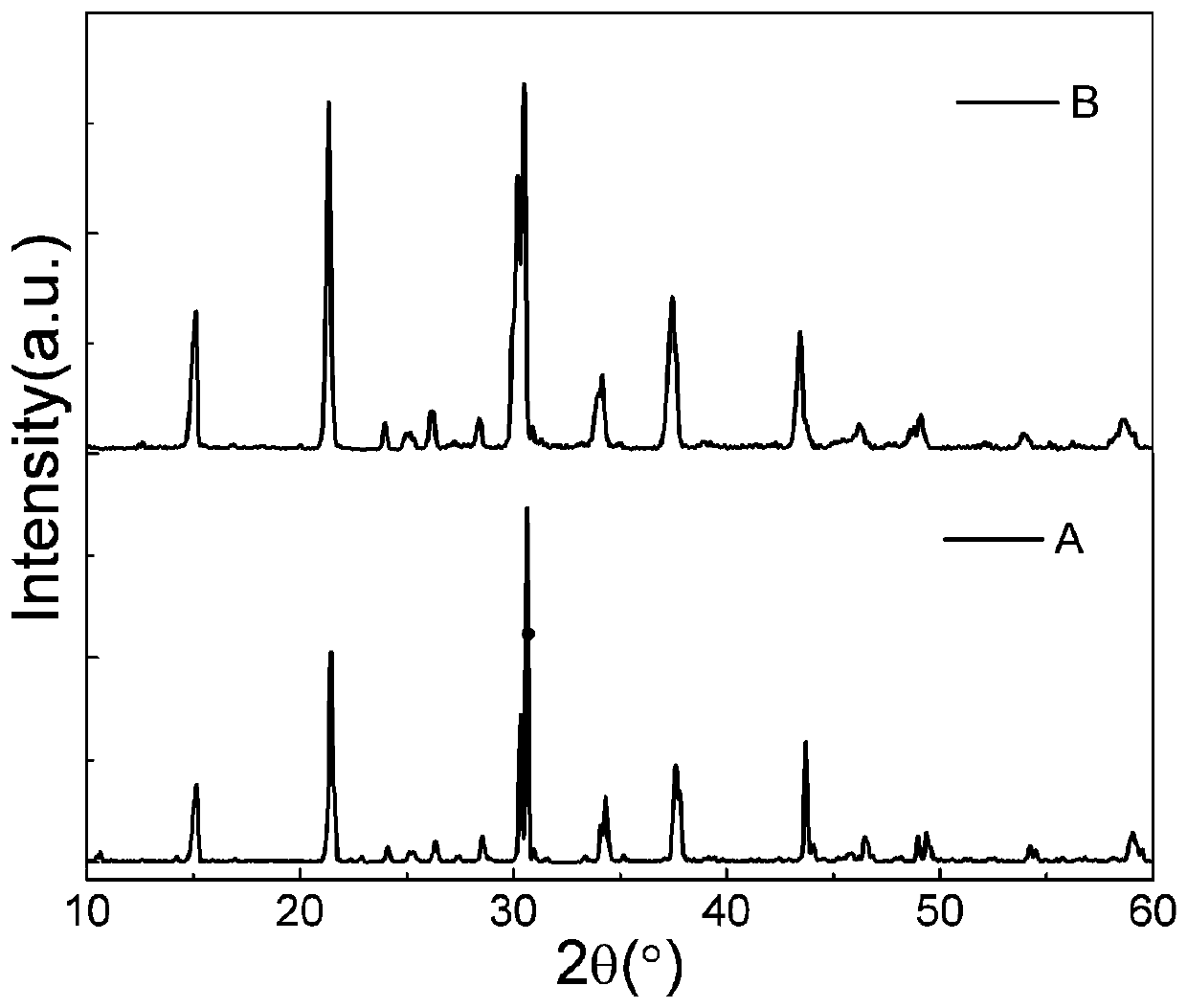

[0046] image 3 A is the CsPbBr that utilizes X-ray diffraction to obtain in embodiment 1 3 XRD for ...

Embodiment 2

[0050] Lead bromide (PbBr 2 ), cesium iodide (CsI) were mixed and dissolved in DMSO at a molar ratio of 1:1, so that the concentration of the mixed solution was 0.4mol / L. After the solution was fully stirred evenly at 40°C, two solvents, DMF and GBL, were added dropwise. The volume ratio of the three solvents was DMSO:DMF:GBL=5:1:1, and the precursor solution dissolved in the ternary mixed solvent was obtained. . After the solution was sealed, it was transferred to a crystal growth tank, and the temperature was raised to 90° C. to start crystal growth. According to the principle of inverse solubility, crystals nucleate and grow spontaneously, and finally obtain large-sized CsPbI x Br 3-x Perovskite single crystal, the single crystal size is about 5mm, where Br:I is 1::1, the ultraviolet absorption edge is at 575nm, and the optical band gap is 2.1eV.

[0051] figure 2 Obtaining CsPbBr for Example 2 3 Physical photos of single crystals;

[0052] image 3 B is the CsPbI ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com