Cloud porcelain wall cloth and manufacturing process thereof

A cloud porcelain and wall covering technology, which is applied in the field of building decoration materials, can solve the problems of insufficient strength of wall leveling layer putty, poor anti-pollution, poor anti-scratch performance, easy to be scratched and damaged, etc., to prolong the decorative effect and meet the material selection requirements Requirements, the effect of reducing maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

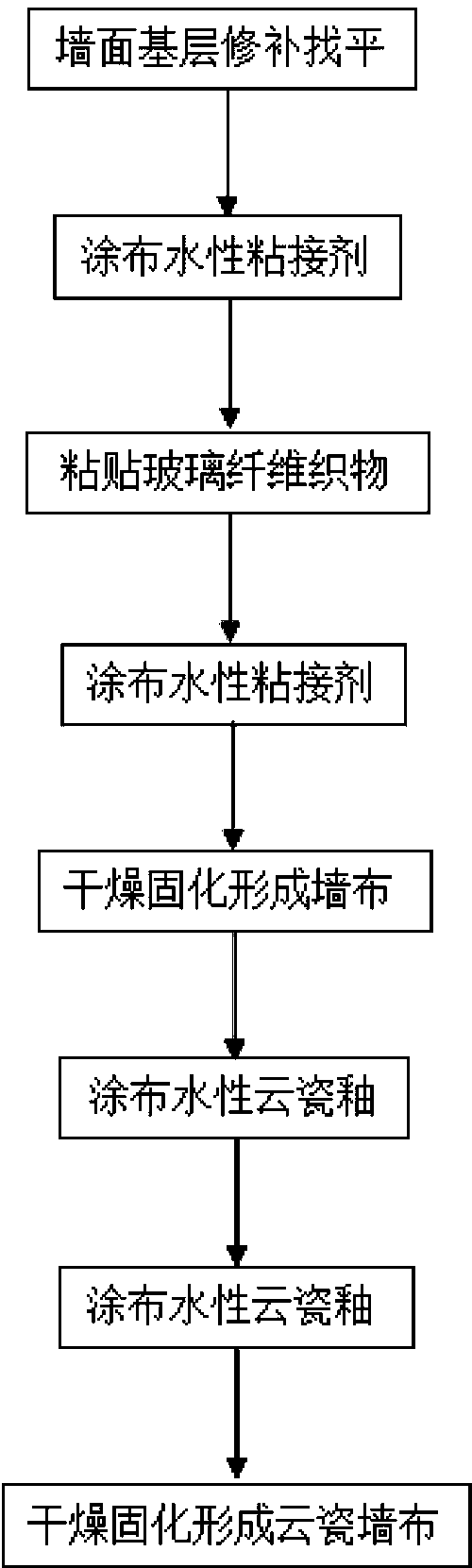

Method used

Image

Examples

Embodiment

[0028] A cloud porcelain wall covering of the present invention comprises a water-based adhesive, a glass fiber fabric and a water-based cloud porcelain glaze;

[0029] Wherein the water-based adhesive includes A component and B component, and the mass ratio of A component to B component is 5:1;

[0030] Component A is composed of epoxy resin, deionized water, silica powder, alkoxy ammonium salt, and polyether siloxane copolymer. The mass ratio of each component is: epoxy resin 43%, deionized water 33%, silica powder 21.5%, alkoxy ammonium salt 1.6%, polyether siloxane copolymer 0.9%;

[0031] Component B is composed of fatty amine, glacial acetic acid, deionized water, and aminodiethoxysilane. The mass ratio of each component is: fatty amine 41%, glacial acetic acid 6%, deionized water 52%, aminodiethoxysilane Silane 1%;

[0032] The water-based cloud enamel includes component C and component D, and the mass ratio of component C to component D is 1:10;

[0033] Component C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com