Electrically-driven optical antenna light source and manufacturing method thereof

A technology of optical antenna and manufacturing method, which is applied to circuits, electrical components, semiconductor devices, etc., can solve the problems of reducing the space size of the light source, the response speed of the light source being limited, the radiation attenuation time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

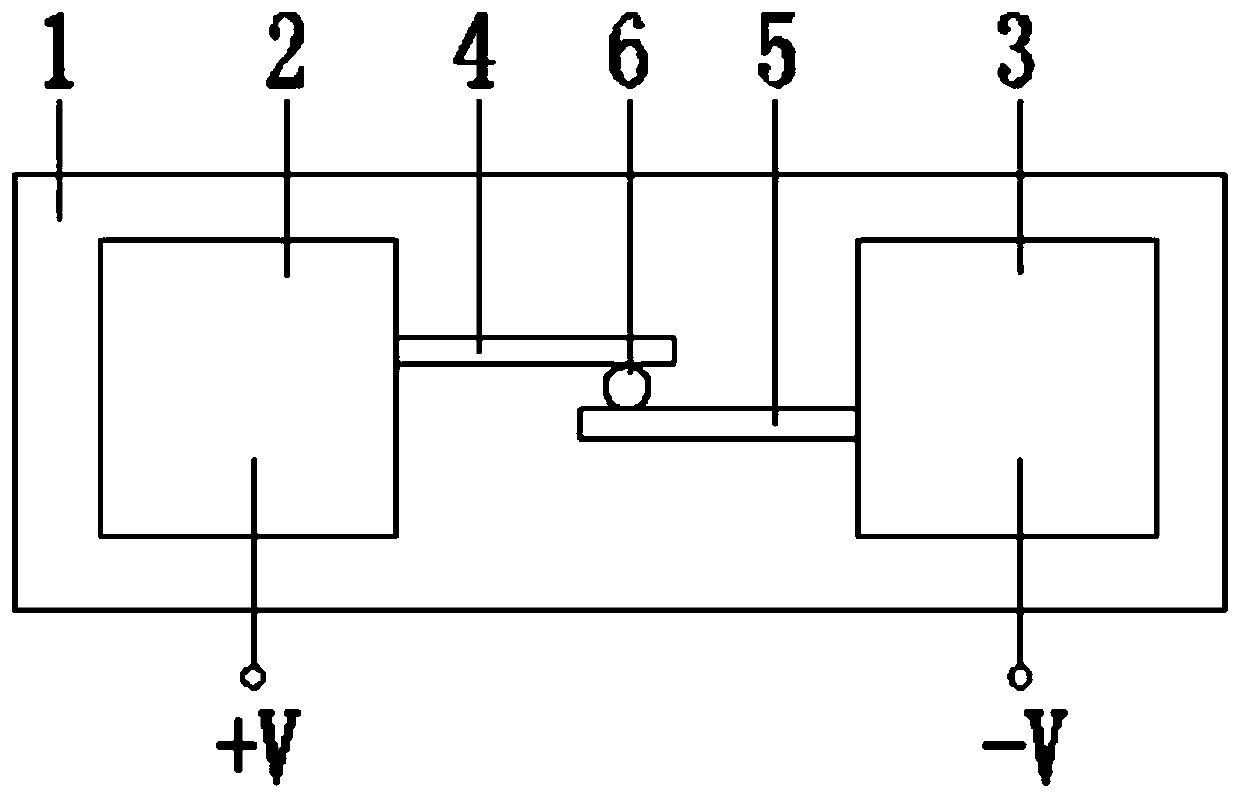

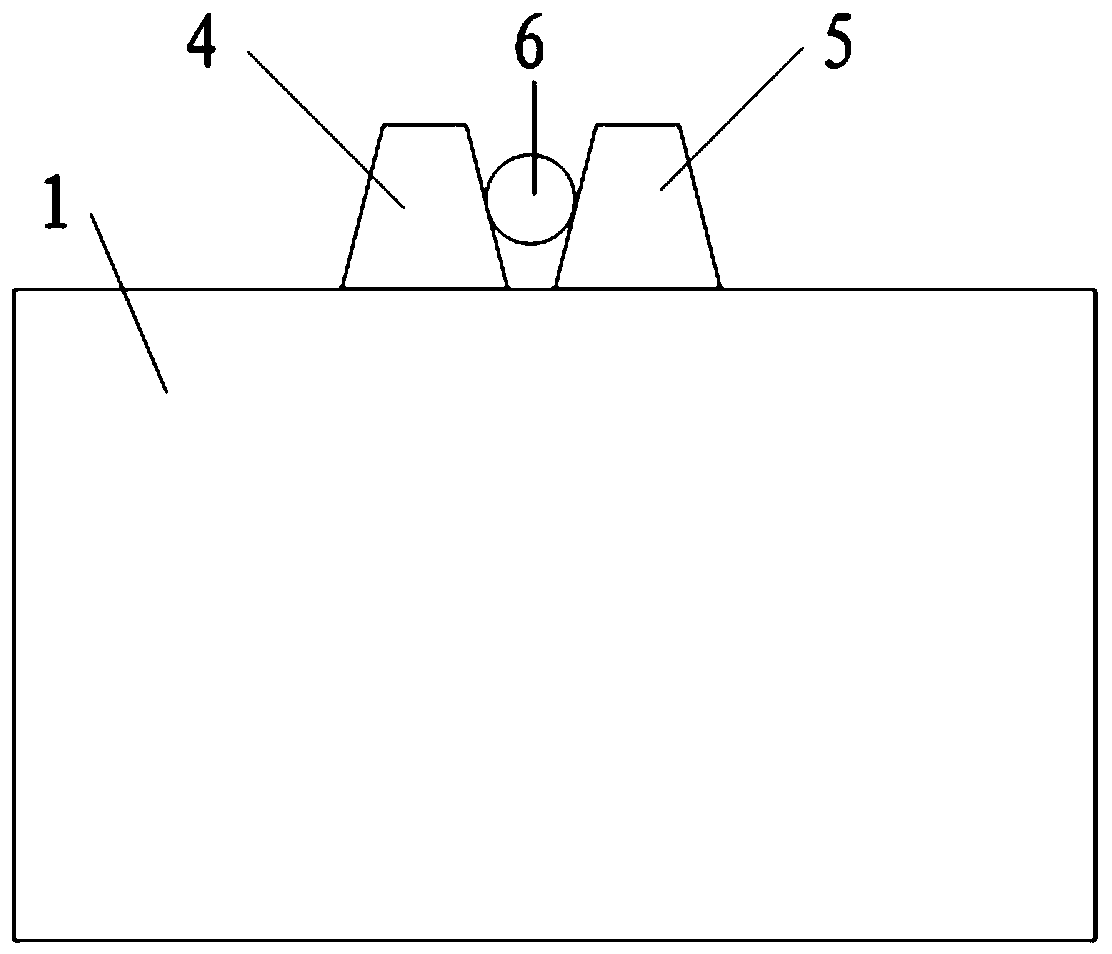

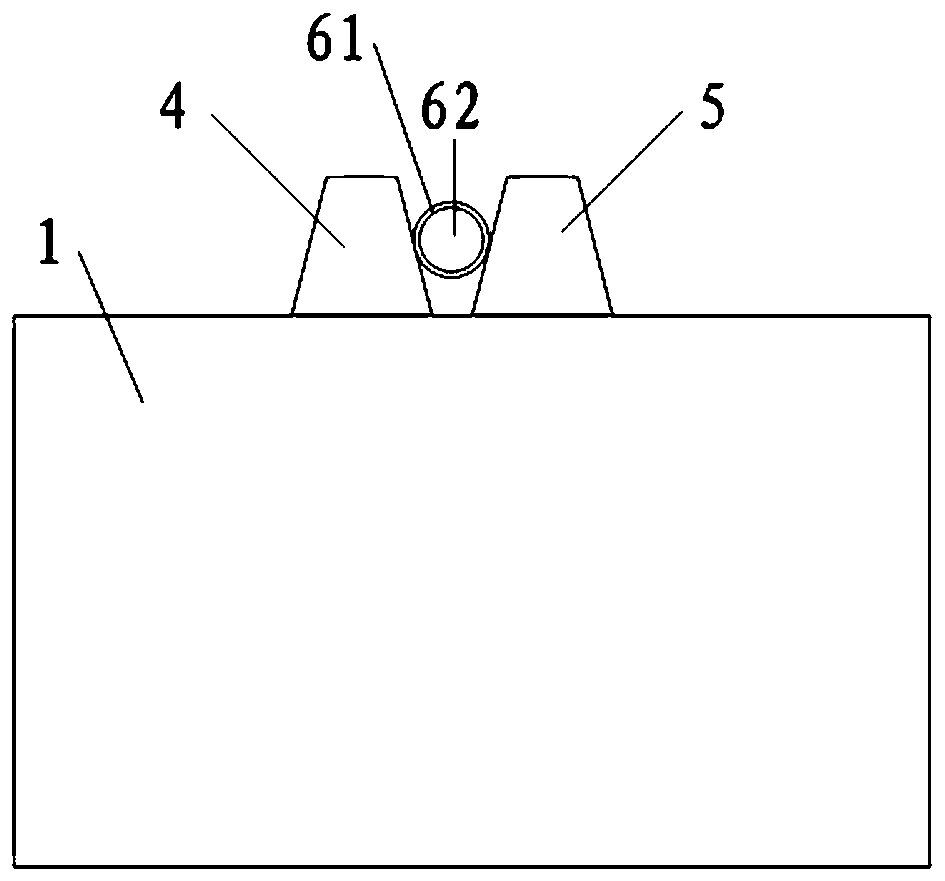

[0029] Embodiment 1: An electrically driven optical antenna light source integrated with a silicon-based optoelectronics circuit, specifically composed of figure 1 , figure 2 , image 3As shown, it includes a substrate 1, a first metal electrode 2, a second metal electrode 3, a first silicon waveguide 4, a second silicon waveguide 5 and an optical antenna 6, and the metal electrodes and the two silicon waveguides are all arranged on the surface of the substrate , the two silicon waveguides are respectively connected to two metal electrodes and a groove is formed between the two silicon waveguides; the optical antenna is located in the groove and is in contact with the two silicon waveguides, and the optical antenna includes metal nanoparticles 62 and is uniformly covered on A layer of insulating dielectric layer 61 on its outer surface. The entire optical antenna is composed of metal, and the entire optical antenna is composed of one or more nanoscale metal nanostructures. ...

Embodiment 2

[0031] The construction of the entire light source includes the following steps:

[0032] Firstly, a device model combining silicon waveguide and optical antenna is established for electromagnetic simulation experiments. Use numerical simulation software such as comsol or FDTD to construct the model structure of the entire device, use a dipole light source or a planar light source to excite the structure, confirm the optical response spectrum of the overall structure and the coupling efficiency of different wavelengths to the waveguide, and adjust the shape of the waveguide The appearance, size, material and structure of the optical antenna can be used to obtain the optimal situation.

[0033] In this embodiment, the entire device is constructed on an SOI substrate, and the substrate is, from top to bottom, a 220nm nano-device silicon layer, a 3-micron silicon oxide insulating layer, and a 500-micron silicon layer. The entire device is constructed from a 220nm device silicon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com