Equipment cooling device

A cooling device and equipment technology, which is applied in the direction of air handling equipment, lighting and heating equipment, heating/cooling equipment, etc., and can solve the problems of compressor power increase and energy consumption increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

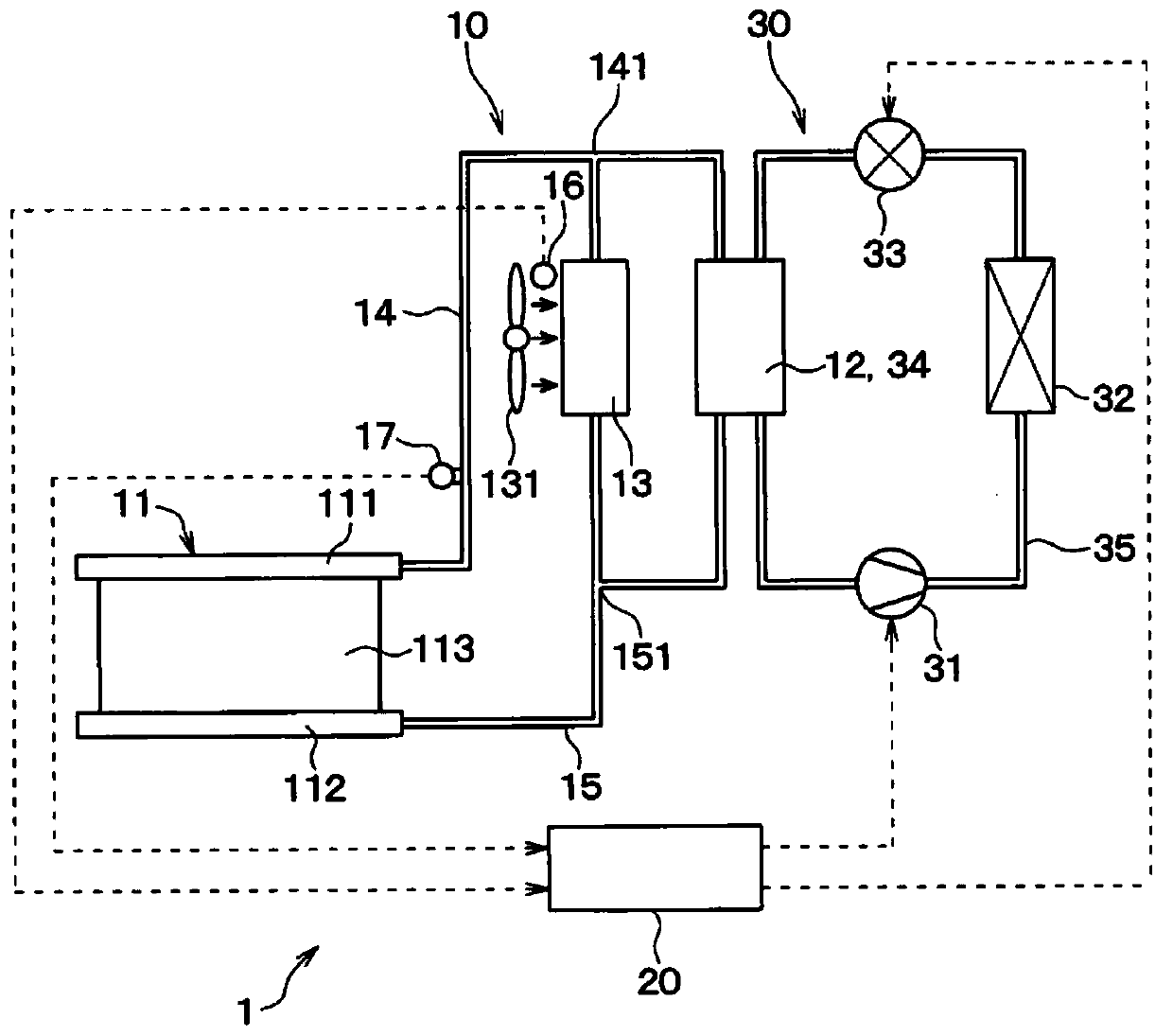

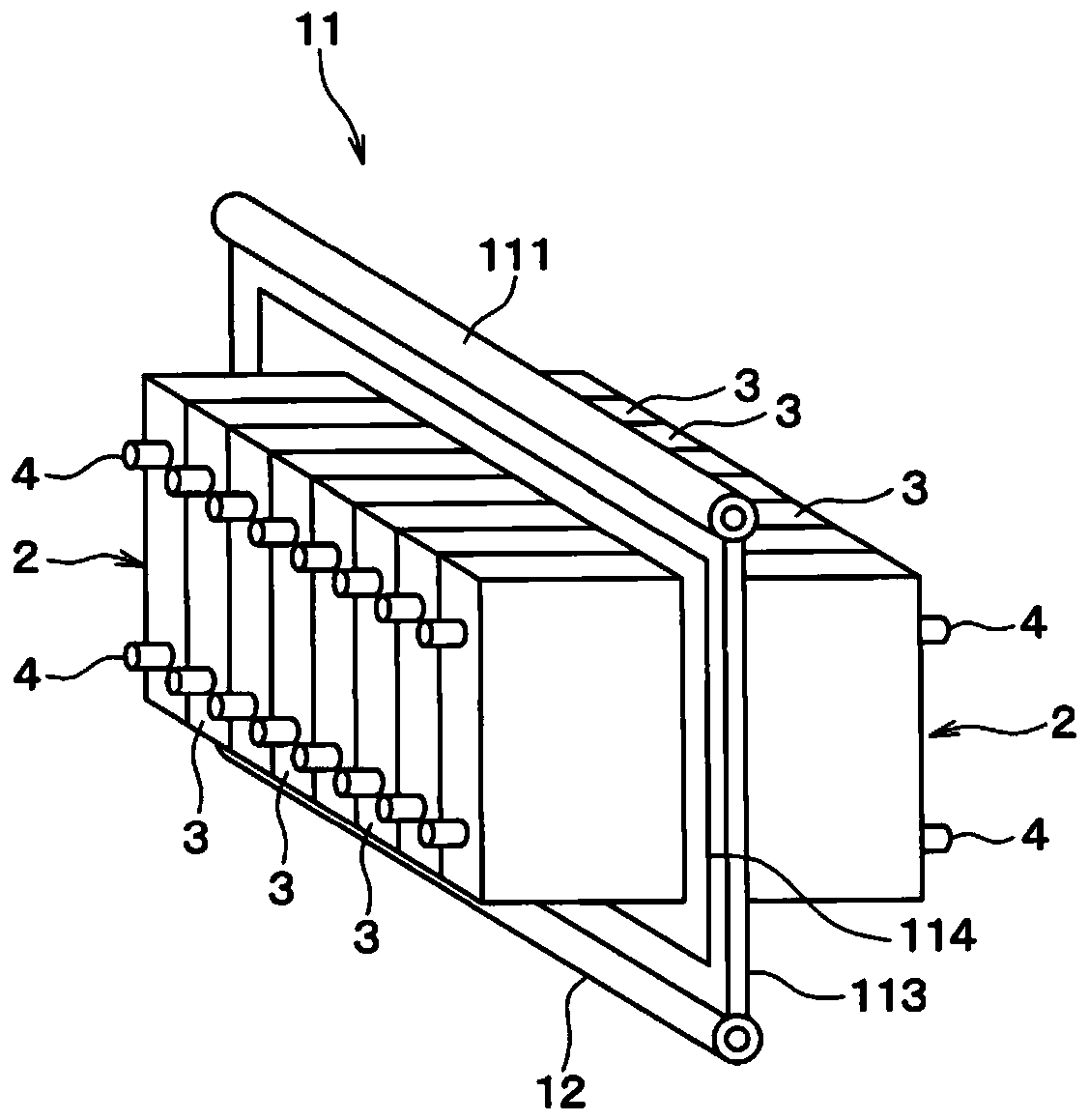

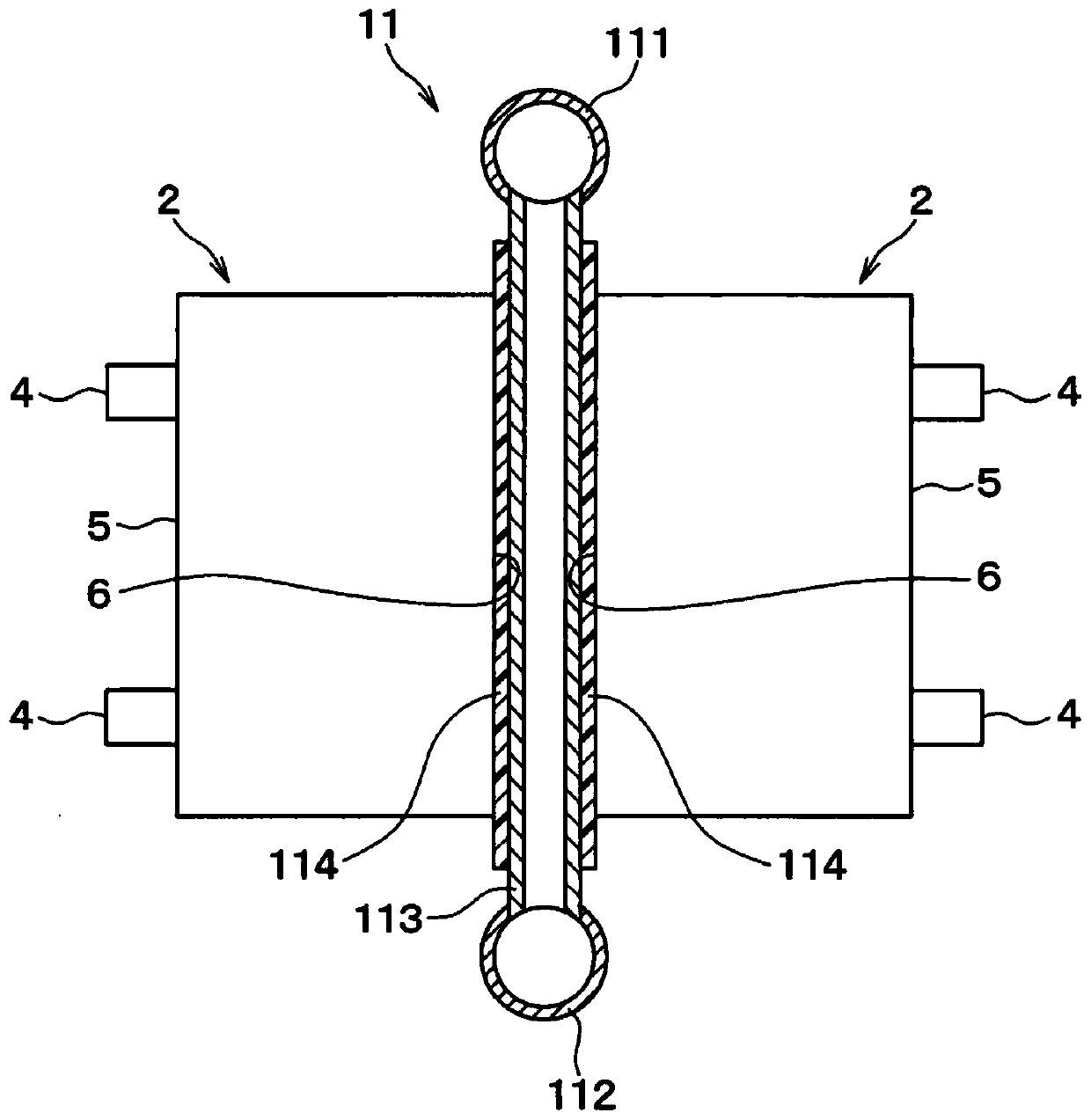

[0047] refer to Figure 1 to Figure 6 The first embodiment will be described. The equipment cooling device 1 of the first embodiment is mounted on an electric vehicle (hereinafter, simply referred to as a “vehicle”) such as an electric vehicle, a plug-in hybrid vehicle, or a hybrid vehicle. The target device to be cooled by the device cooling device 1 of the first embodiment is a secondary battery (hereinafter, referred to as "assembled battery 2") mounted on a vehicle.

[0048] First, the assembled battery 2 to be cooled by the equipment cooling device 1 will be described. The large assembled battery 2 installed in a vehicle is a battery pack (ie, a power storage device) in which a plurality of battery packs are assembled, and is mounted under a seat or a luggage compartment of the vehicle. The electric power stored in the assembled battery 2 is supplied to the vehicle traveling motor via an inverter or the like. That is, the assembled battery 2 stores and discharges the e...

no. 2 approach

[0092] The second embodiment will be described. The second embodiment will specifically describe the configuration of the heat dissipation adjusting portion with respect to the first embodiment, and the other contents are the same as those of the first embodiment, so only the parts different from the first embodiment will be described.

[0093] The heat radiation amount adjustment unit included in the equipment cooling device 1 of the second embodiment is the compressor 31 included in the refrigeration cycle 30 . The compressor 31 serving as the heat radiation amount adjustment unit can be adjusted by reducing the rotation speed so that the flow rate of the refrigerant circulating in the refrigeration cycle 30 is reduced so that the refrigerant evaporator 34 (ie, the cold heat source heat exchanger 12 ) The heat dissipation amount of the working fluid flowing in it becomes small.

[0094] For the control process executed by the control device 20 included in the equipment cool...

no. 3 approach

[0099] A third embodiment will be described. In the third embodiment as well, the configuration of the heat radiation amount adjustment unit is specifically described with respect to the first embodiment, and the other contents are the same as in the first embodiment.

[0100] The heat radiation amount adjustment unit included in the equipment cooling device 1 of the third embodiment is the expansion valve 33 included in the refrigeration cycle 30 . The expansion valve 33 serving as the heat radiation amount adjusting portion can be adjusted by reducing the flow path area so that the heat radiation amount of the working fluid flowing in the refrigerant evaporator 34 (ie, the cold heat source heat exchanger 12 ) is reduced.

[0101] Figure 8 It is a graph showing the relationship between the degree of superheat of the refrigerant flowing out of the refrigerant evaporator 34 and the cooling capacity by the refrigerant evaporator 34 in the refrigeration cycle 30 . When the flo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com