Vegetal and thick flavor powder

A rich-tasting, plant-based technology, applied in food science, food ingredients as taste improvers, applications, etc., can solve problems that cannot satisfy consumers' picky taste buds, and achieve natural and rich aroma, strong flavor, and enhanced effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (a) Mix 25 parts of soybean protein and 70 parts of soft water evenly, heat to 45°C, add 1.5 parts of plant protein decomposing compound enzyme, react for 3 hours, and filter with 40 mesh to obtain primary fragrance liquid.

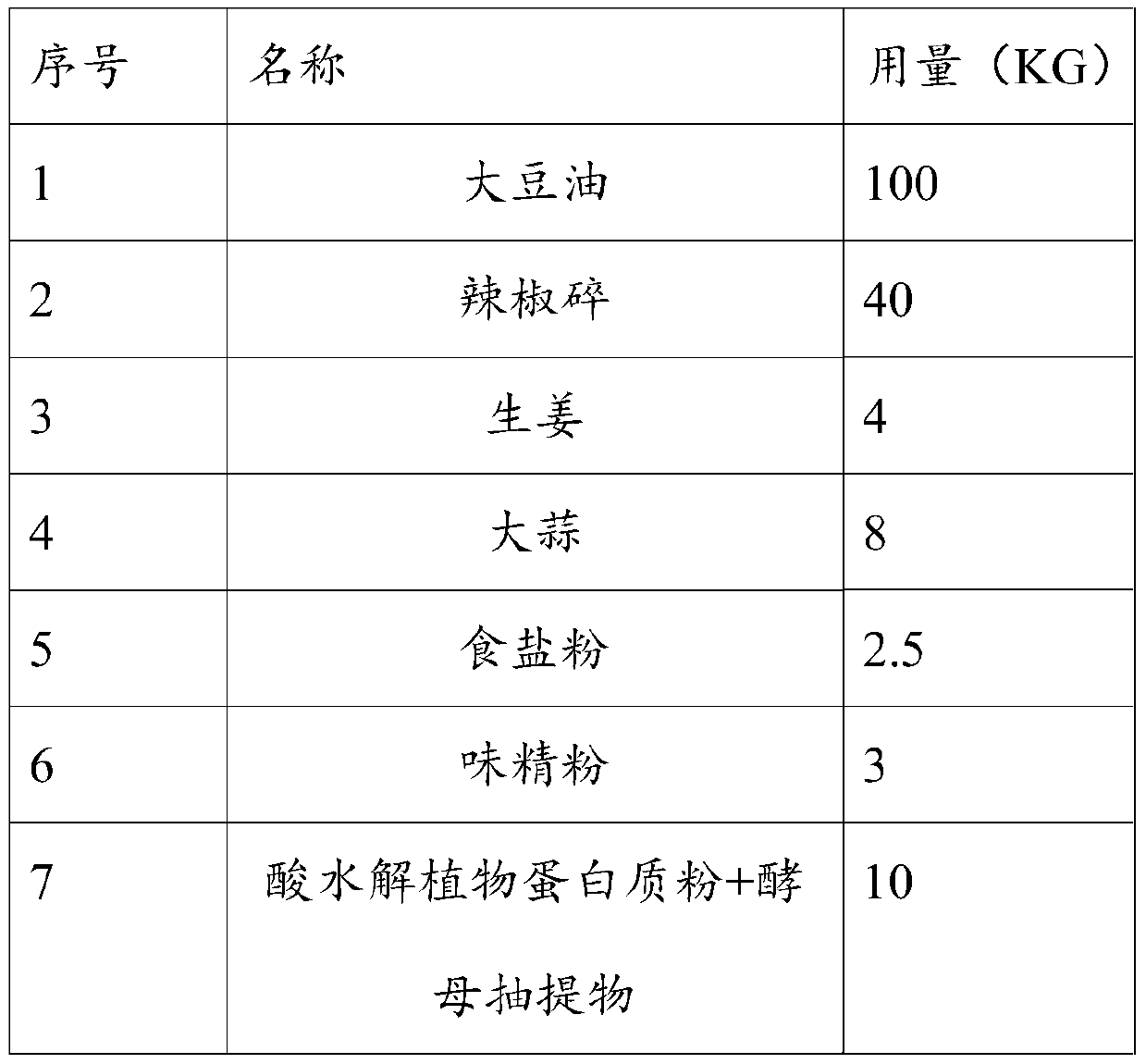

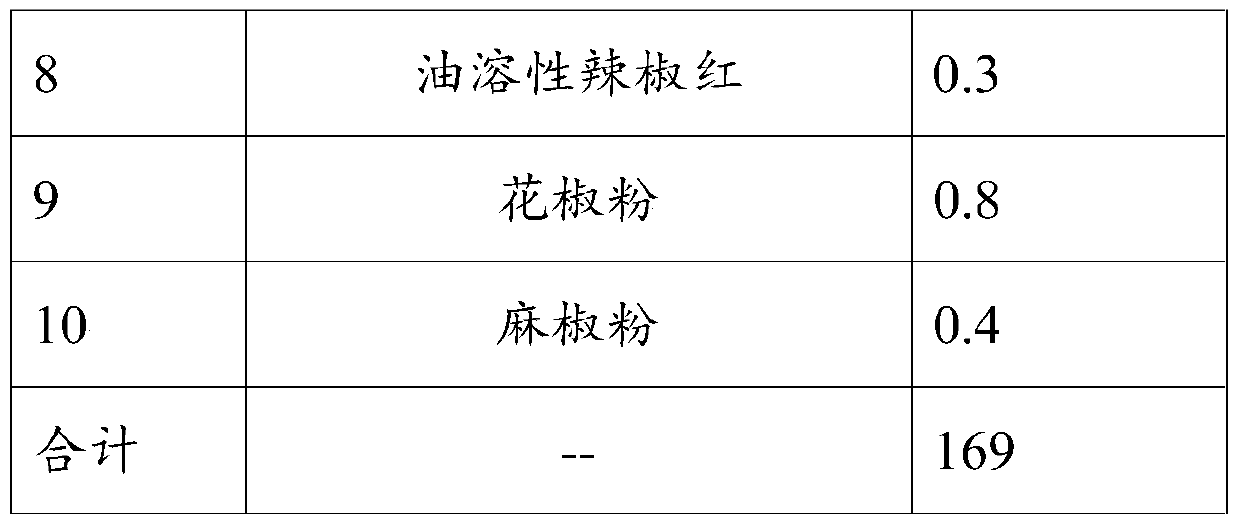

[0021] (b) 20 parts of the primary fragrance liquid, 20 parts of sour water gluten protein hydrolyzate, 15 parts of yeast extract, 10 parts of tomato paste, 2 parts of shiitake mushroom extract, 1.5 parts of palm oil, and 1 part of thiamine hydrochloride Mix well with 1.2 parts of L-glutamic acid, heat to 50-70°C, adjust the pH value to 6.5 after all dissolve, raise the temperature to 98°C for 3.5 hours of stewing reaction, and obtain the secondary aroma liquid.

[0022] (c) Mix 90 parts of the secondary flavoring liquid, 8 parts of fermented soy sauce liquid and 2 parts of spices evenly, heat up to 95° C., and sterilize for 25 to 60 minutes to obtain the third flavoring liquid to be dried.

[0023] (d) The tertiary fragrance liquid to be dried is ...

Embodiment 2

[0026] (a) Mix 30 parts of soybean protein and 70 parts of soft water, heat it to 45°C, add 1.5 parts of plant protein decomposing complex enzyme, react for 2.5 hours, and filter with a 40-mesh filter to obtain a primary fragrance liquid;

[0027] (b) 20 parts of the primary fragrance liquid, 20 parts of sour water gluten protein hydrolyzate, 15 parts of yeast extract, 8 parts of tomato sauce, 2 parts of shiitake mushroom extract, 1.5 parts of soybean oil, and 1 part of thiamine hydrochloride Mix well with 1.2 parts of L-glutamic acid, heat to 50-70°C, adjust the pH value to 6.5 after all dissolve, raise the temperature to 98°C for 3.5 hours of stewing reaction, and obtain the secondary flavor liquid;

[0028] (c) 80 parts of the secondary flavoring liquid, 8 parts of fermented soy sauce liquid, 2 parts of spices, etc. are evenly mixed, heated to 95° C., and sterilized for 25 to 60 minutes to obtain the third flavoring liquid to be dried.

[0029] (d) Emulsify the third raw fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com