ZnO functional nano material and preparation method thereof

A technology of functional nano and zinc oxide nano crystals, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., to achieve the effect of low reaction temperature, good uniformity and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

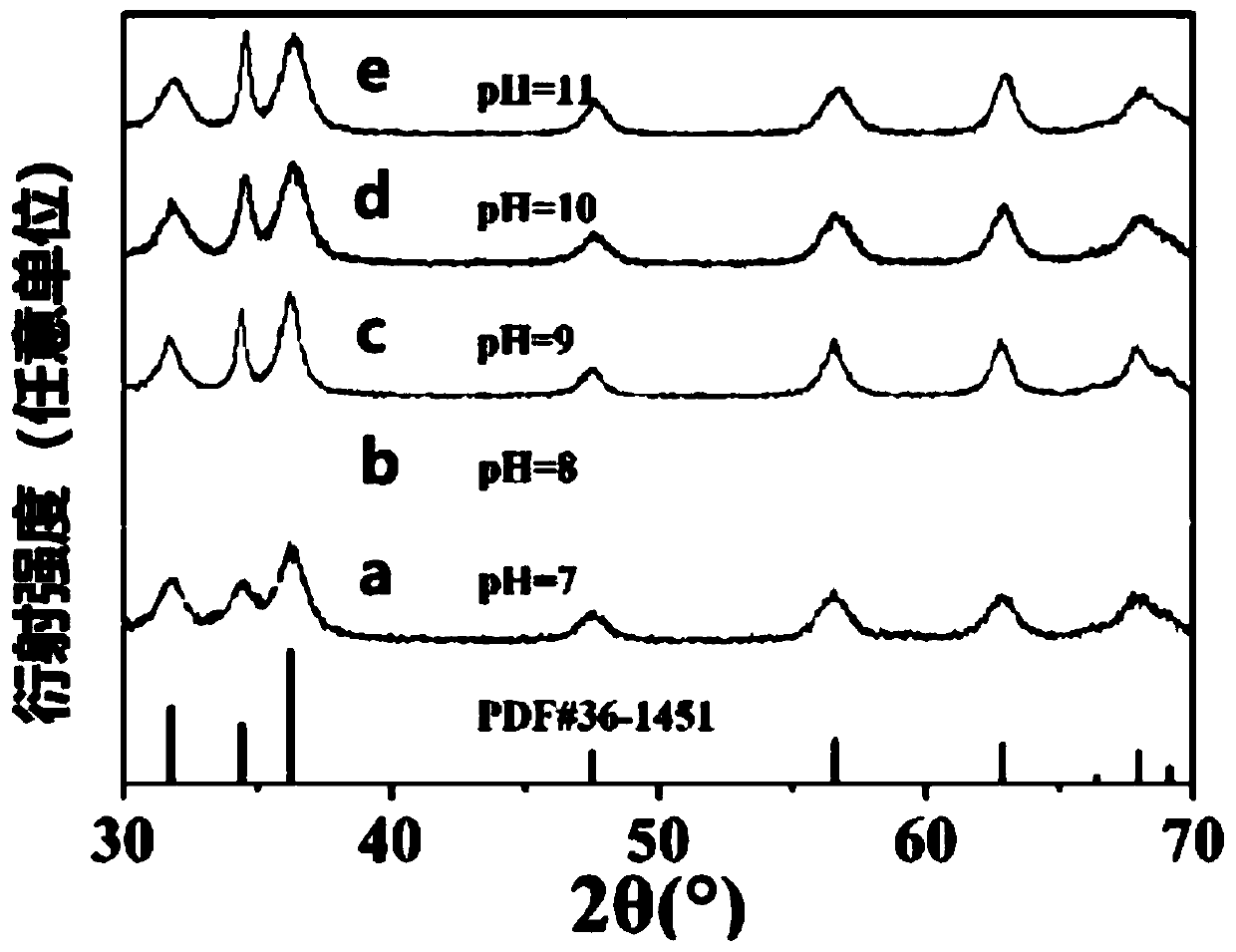

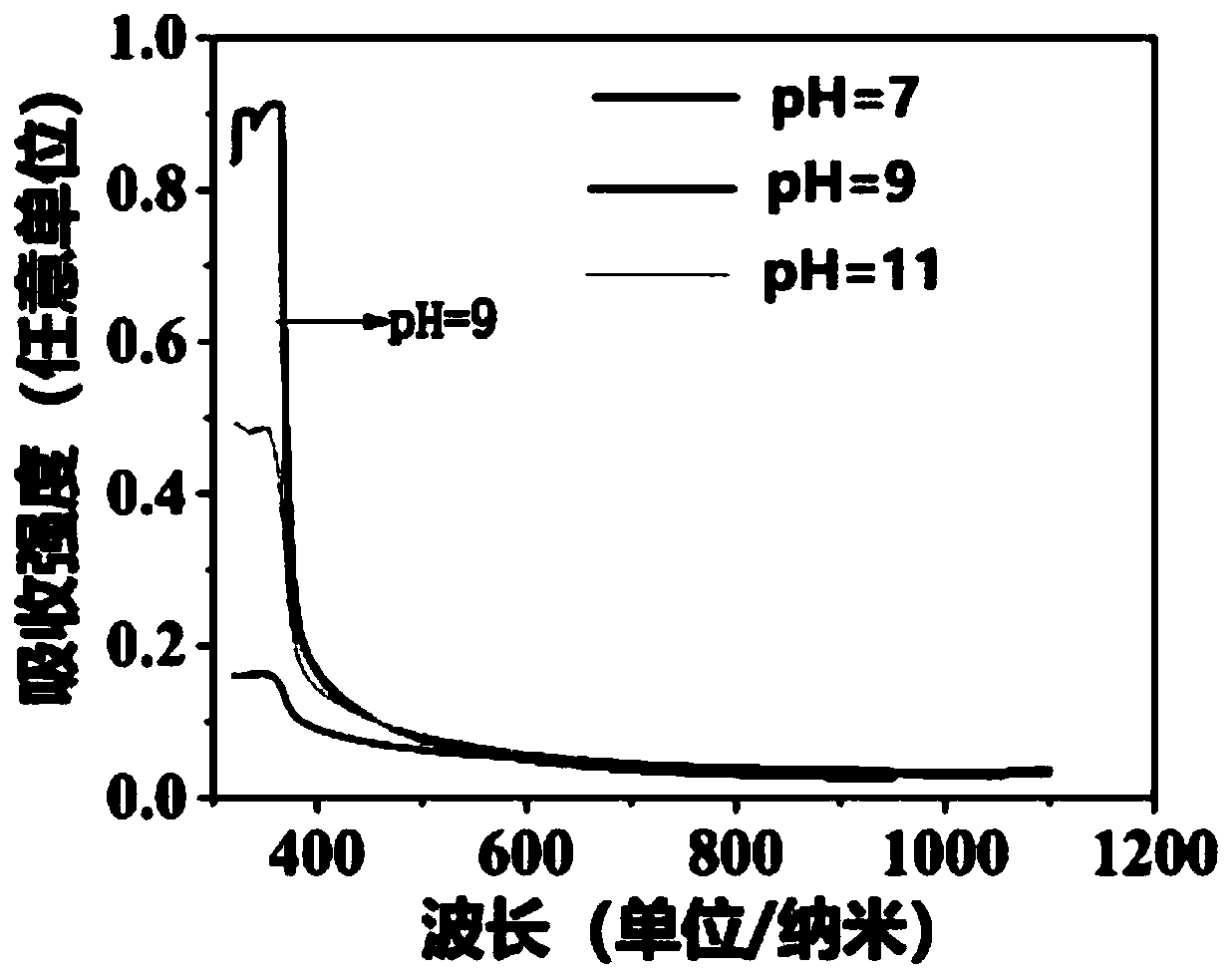

[0025] A method for preparing ZnO functional nanomaterials at near room temperature, the ZnO functional nanomaterials have strong purple light absorption, the method comprising:

[0026] (S1) Take 5mL deionized water and 5mL methanol into a dry 100mL beaker according to the volume ratio of 1:1, then stir fully to form a uniform solvent, and heat to 45°C at the same time to obtain methanol / water solution;

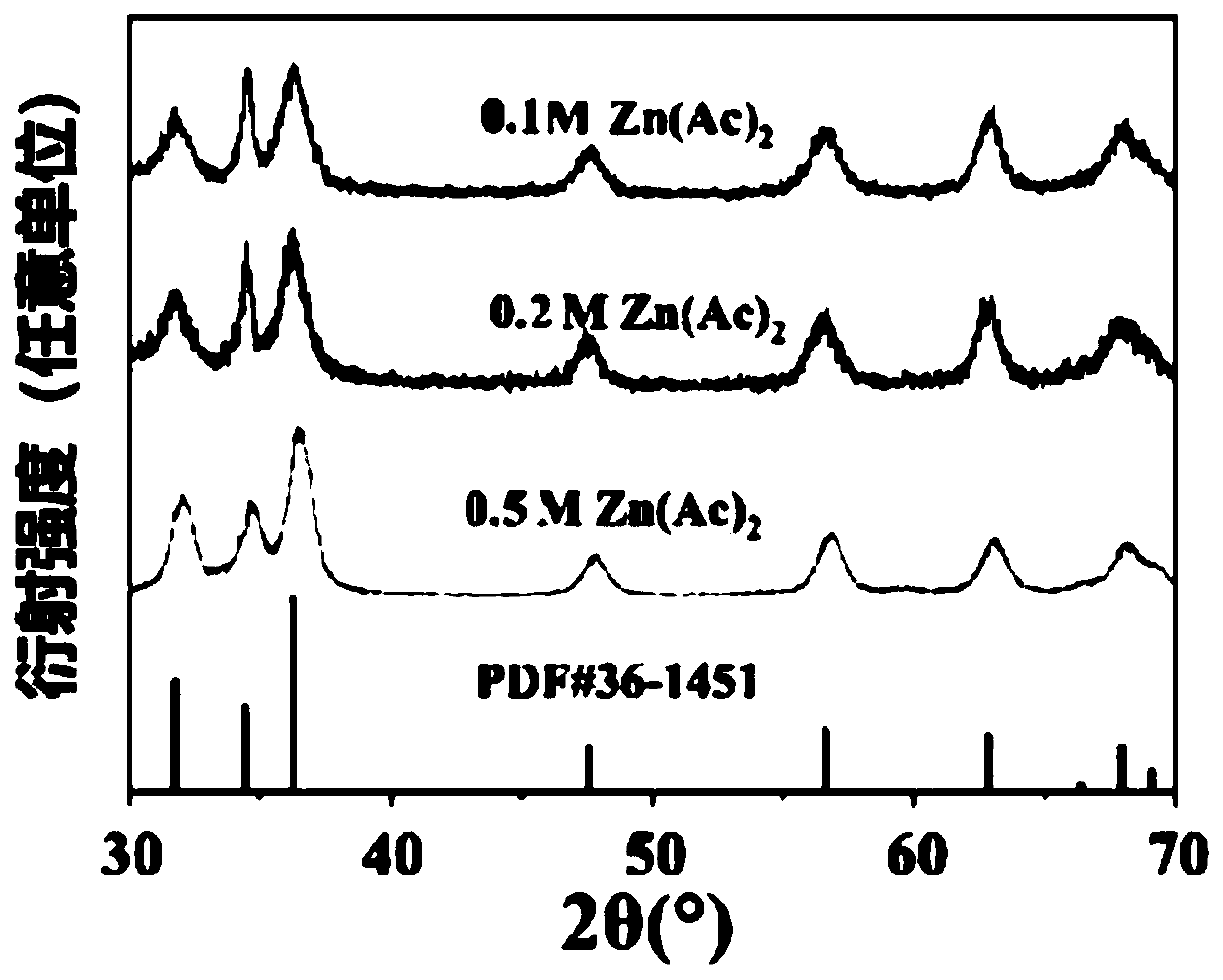

[0027] (S2) Use a pipette gun to measure 20 mL of an aqueous zinc acetate solution with a concentration of 0.2 mol / L and drop it into the aqueous methanol solution at 45° C. in step (S1);

[0028] (S3) heating the solution obtained in step (S2) to 50° C. and keeping it warm for 5 minutes to form a uniform solution, and this temperature is conducive to the subsequent reaction, which can make the crystal growth rate appropriate;

[0029] (S4) The solution obtained in step (S3) is added dropwise with a methanol solution of sodium hydroxide until the value displayed by the pH te...

Embodiment 2

[0033] A method for preparing ZnO functional nanomaterials at near room temperature, the method comprising:

[0034] (S1) Add 5mL deionized water and 5mL methanol into a dry 100mL beaker according to the volume ratio of 1:1; then fully stir to form a uniform solvent, and heat to 45°C at the same time;

[0035] (S2) Use a pipette gun to measure 20 mL of zinc acetate aqueous solution with a concentration of 0.2 mol / L and drop it into the methanol / water solution prepared in step (S1);

[0036] (S3) heating the solution obtained in step (S2) to 50° C. and keeping it warm for 5 minutes, the purpose is to form a uniform solution, and this temperature is conducive to subsequent reactions, which can make the crystal growth rate appropriate;

[0037] (S4) Add methanol solution of sodium hydroxide dropwise to the solution obtained in step (S3) until the value displayed by the pH tester is 9, seal the reaction vessel, and raise the temperature to 55° C. and keep it for 2 hours to obtain ...

Embodiment 3

[0041] A method for preparing ZnO functional nanomaterials at near room temperature, the method comprising:

[0042] (S1) Add 5 mL of deionized water and 5 mL of methanol into a dry 100 mL beaker according to the volume ratio of 1:1; then fully stir to form a uniform solvent, and heat to 45 degrees Celsius at the same time;

[0043] (S2) Use a pipette gun to measure a zinc acetate aqueous solution with a concentration of 0.2mol / L and drop it into the methanol / water solution prepared in step (S1);

[0044] (S3) heating the solution obtained in step (S2) to 50° C. and keeping it warm for 5 minutes to form a uniform solution;

[0045] (S4) Add methanol solution of sodium hydroxide dropwise to the solution obtained in step (S3) until the value displayed by the pH tester is 11, seal the reaction vessel, and raise the temperature to 55° C. and keep it for 2 hours to obtain a milky white suspension. The turbid liquid is methanol suspension of ZnO;

[0046](S5) Naturally cool the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com