Method for increasing yield of methane by using anaerobic granular sludge loaded with biological nano Fe3O4

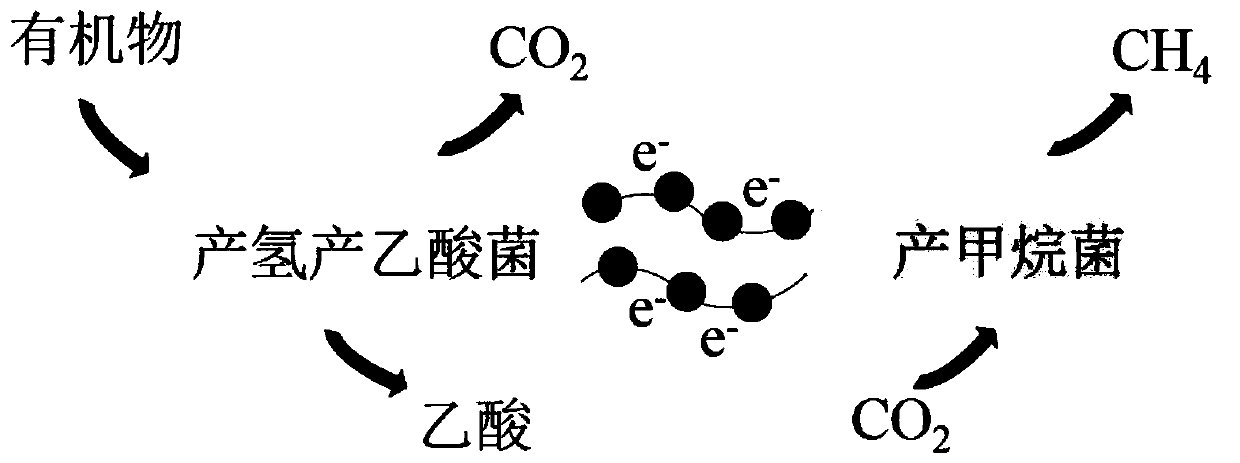

An anaerobic granular sludge and bio-nano technology, applied in the field of anaerobic biological treatment, can solve the problems of high price, complicated preparation process, and the role of microbial electron transfer process in difficult particles, so as to improve efficiency, simple operation, and promote Effects of direct interspecies electron transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

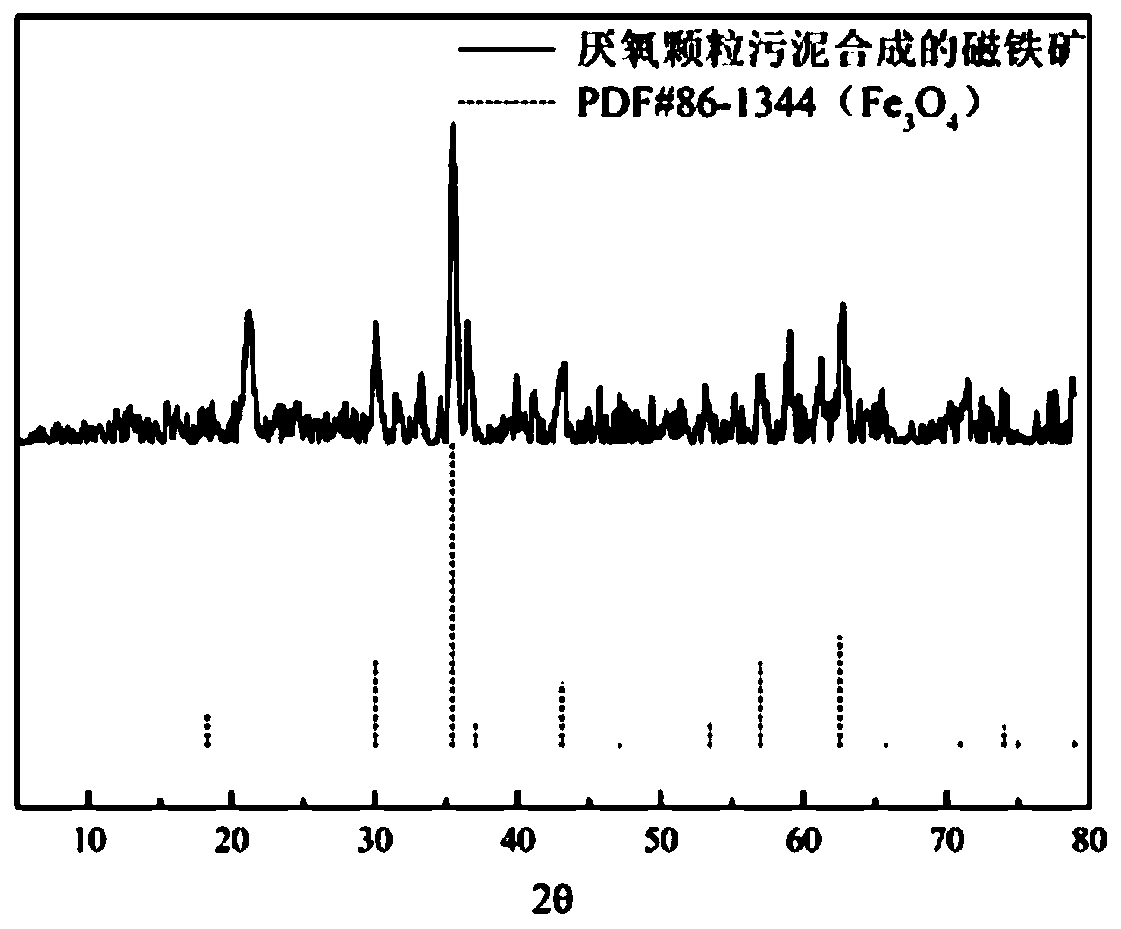

Examples

Embodiment 1

[0028] The composition of the trace element solution is as follows: NiSO 4 ·6H 2 0=500mg / L, MnCl 2 ·4H 2 0=500mg / L, FeSO 4 ·7H 2 0=500mg / L, ZnSO 4 ·7H 2 0=100mg / L, H 3 BO 3 =100mg / L, Na 2 MoO 4 ·2H 2 0=50mg / L, CoCl 2 ·6H 2 0=50mg / L, CuSO 4 ·5H 2 0=5mg / L.

[0029] The composition of the inorganic salt culture solution is as follows: NH 4 HCO 3 =460mg / L, KH 2 PO 4 =70mg / L, NaHCO 3 =1000mg / L, CaCl 2 =7.5mg / L, trace element solution is 1mL / L.

[0030] 1) Take the anaerobic granular sludge from the sewage treatment plant, wash it with the inorganic salt culture solution prepared above, and then place it in the headspace bottle to add the inorganic salt culture solution, and then use glucose as the carbon source to add it to the inorganic salt culture solution , To obtain the anaerobic granular sludge mixture, so that the glucose concentration in the anaerobic granular sludge mixture is 2500mg / L, and the sludge concentration is 4g MLVSS / L.

[0031] 2) Prepare FeCl with a concentration of 0...

Embodiment 2

[0038] 1) Take the anaerobic granular sludge from the sewage treatment plant and wash it with the inorganic salt culture solution prepared in Example 1, then place it in a headspace bottle to add the inorganic salt culture solution, and then use glucose as the carbon source to add it to the inorganic salt culture In the liquid, an anaerobic granular sludge mixture is obtained, so that the glucose concentration in the anaerobic granular sludge mixture is 2500 mg / L and the sludge concentration is 4 g MLVSS / L.

[0039] 2) Prepare FeCl with a concentration of 0.4mol / L 3 ·6H 2 O solution and NaOH solution with a concentration of 10mol / L, in FeCl 3 ·6H 2 The NaOH solution was slowly added to the O solution while stirring to pH=7, and the obtained precipitate was washed with water to obtain an amorphous iron oxyhydroxide suspension.

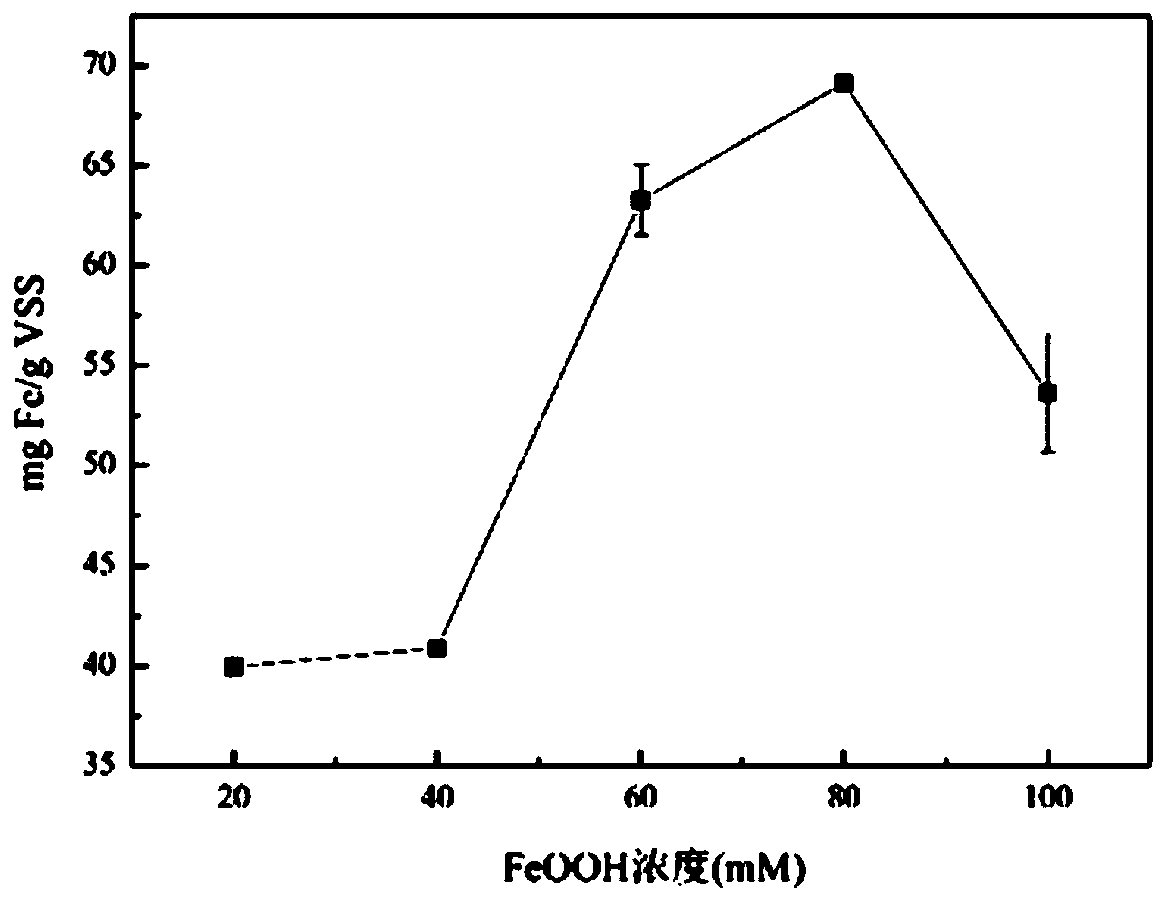

[0040] Add amorphous iron oxyhydroxide suspension and sodium acetate as an electron donor to the anaerobic granular sludge mixture to make the iron oxyhydrox...

Embodiment 3

[0046] 1) Take the anaerobic granular sludge from the sewage treatment plant and wash it with the inorganic salt culture solution prepared in Example 1, then place it in a headspace bottle to add the inorganic salt culture solution, and then use glucose as the carbon source to add it to the inorganic salt culture In the liquid, an anaerobic granular sludge mixture is obtained, so that the glucose concentration in the anaerobic granular sludge mixture is 2500 mg / L and the sludge concentration is 4 g MLVSS / L.

[0047] 2) Prepare FeCl with a concentration of 0.4mol / L 3 ·6H 2 O solution and NaOH solution with a concentration of 10mol / L, in FeCl 3 ·6H 2 The NaOH solution was slowly added to the O solution while stirring to pH=7, and the obtained precipitate was washed with water to obtain an amorphous iron oxyhydroxide suspension.

[0048] Add amorphous iron oxyhydroxide suspension and sodium pyruvate as an electron donor to the anaerobic granular sludge mixture to make the concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com