Catalyst, reaction device and reaction method for mild hydrocracking of f-t synthetic wax oil

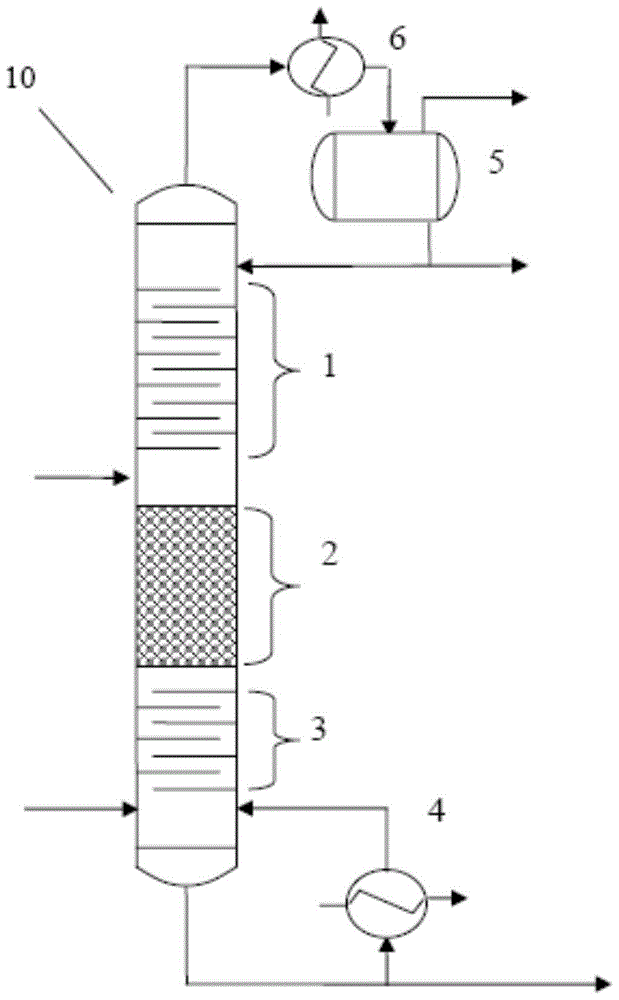

A hydrocracking and catalyst technology, applied in hydrocarbon oil cracking, molecular sieve catalysts, chemical instruments and methods, etc., to achieve high activity and selectivity, unique three-dimensional structure, and high heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

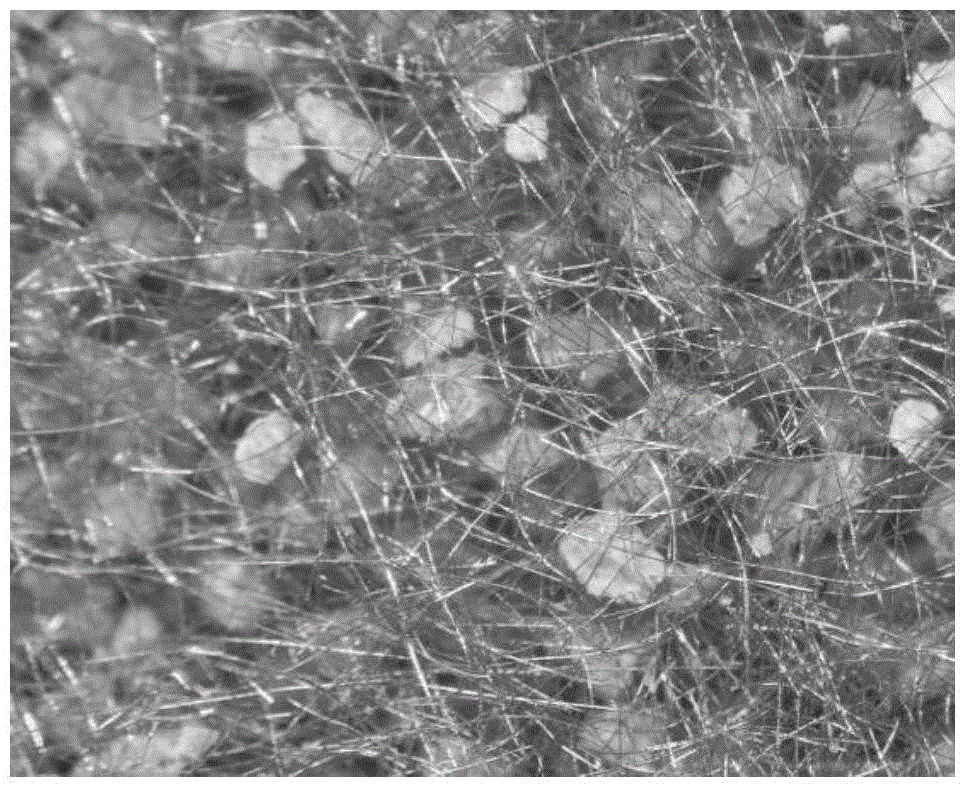

[0042] Mix 4.2g Ni fiber (diameter 8μm, length 2-3mm), 7.5g 80-100 mesh SAB carrier particles, 1.4g cellulose, appropriate amount of industrial ethanol, mix them into 1L water for beating, and make a thin layer with a diameter of 160mm on a paper forming machine Filter cake, put the obtained thin-layer filter cake in the air to dry at 110°C, oxidize in the air at 500°C for 1 hour, and bake in the hydrogen atmosphere at 950°C for 1 hour, so that the contact points of Ni microfibers are sintered and fused to form SAB Pt / SAB catalyst precursor with support particles firmly bound in a three-dimensional network of Ni microfibrils. Then measure an appropriate amount of chloroplatinic acid solution, impregnate the catalyst using an equal volume impregnation method, dry at 110°C for 12h, and roast at 550°C for 5h to obtain a Ni fiber structured Pt / SAB catalyst (the mass content of the impregnated active component Pt is 0.8%), and its optical microscope appearance is as follows figur...

Embodiment 2

[0044] Mix 4.2g Cu fiber (diameter 8μm, length 2-3mm), 4.0g 80-100 mesh SAB carrier particles, 1.4g cellulose, appropriate amount of industrial ethanol, mix them into 1L water for beating, and make a thin layer with a diameter of 160mm on a paper forming machine For filter cake, dry the obtained thin layer filter cake in air at 110°C, oxidize in air at 500°C for 1 hour, and bake in hydrogen atmosphere at 850°C for 1 hour, so that the contact points of Cu microfibers are sintered and fused to form SAB Pt / SAB catalyst precursor with support particles firmly bound in a three-dimensional network of Cu microfibrils. Then measure an appropriate amount of chloroplatinic acid solution, impregnate the catalyst with an equal volume impregnation method, dry at 110 °C for 12 h, and roast at 550 °C for 6 h in a nitrogen atmosphere to obtain a Cu fiber-structured Pt / SAB catalyst (the impregnated active component Pt The mass content is 0.8%).

Embodiment 3

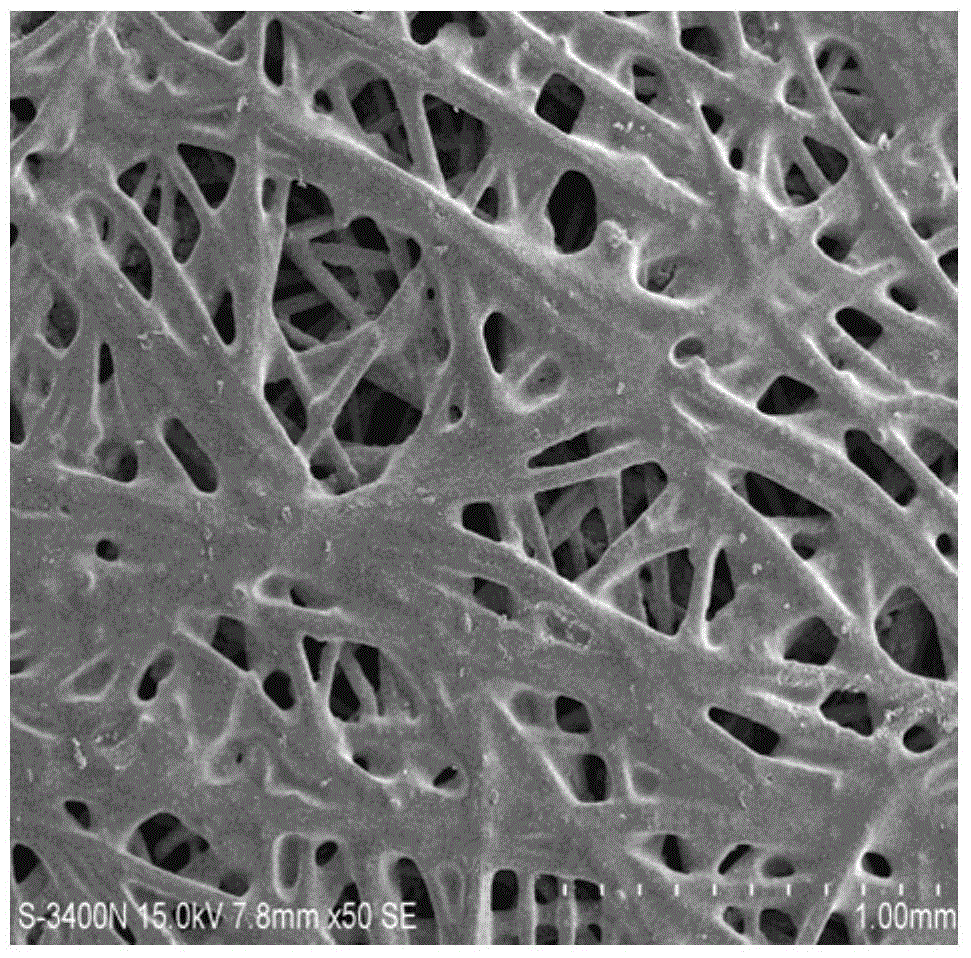

[0046] Immerse 4.2g Al fiber (diameter 50μm, length 2~3mm) in 1% silica sol 1%ZMS-5 seed crystal suspension for 10s, take it out and dry it in the shade, roast it, then add 34.8% orthosilicate ethyl ester and 35.6% Tetra Propyl ammonium hydroxide was crystallized in the crystallization solution of 0.3% sodium metaaluminate for 48 hours, and then washed and dried at 110°C to obtain a fiber growth molecular sieve carrier. Weigh 6.7g of the prepared fiber-growth molecular sieve and impregnate it with an equal volume of chloroplatinic acid solution, dry at 110°C for 12h, and calcinate at 550°C for 6h to prepare an Al fiber-structured Pt / Al catalyst (the impregnated active component Pt The mass content is 0.8%), and its scanning electron microscope is as follows image 3 shown.

[0047] The catalysts of Comparative Examples 1-2 and Examples 1-3 were used for the mild hydrocracking reaction of F-T synthetic wax oil. The reactions in which the catalysts of Examples 1-3 participate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com