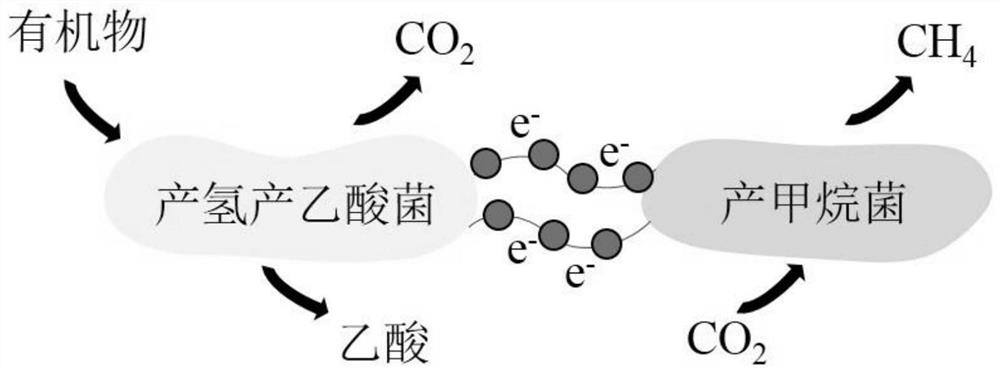

A loaded bionano fe 3 o 4 Anaerobic Granular Sludge as a Method for Improving Methane Production

An anaerobic granular sludge and bio-nano technology, which is applied in the field of anaerobic biological treatment, can solve the problems of difficult particle internal microbial electron transfer process, complex preparation process, high price, etc., to achieve the promotion of direct interspecies electron transfer, Ease of operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

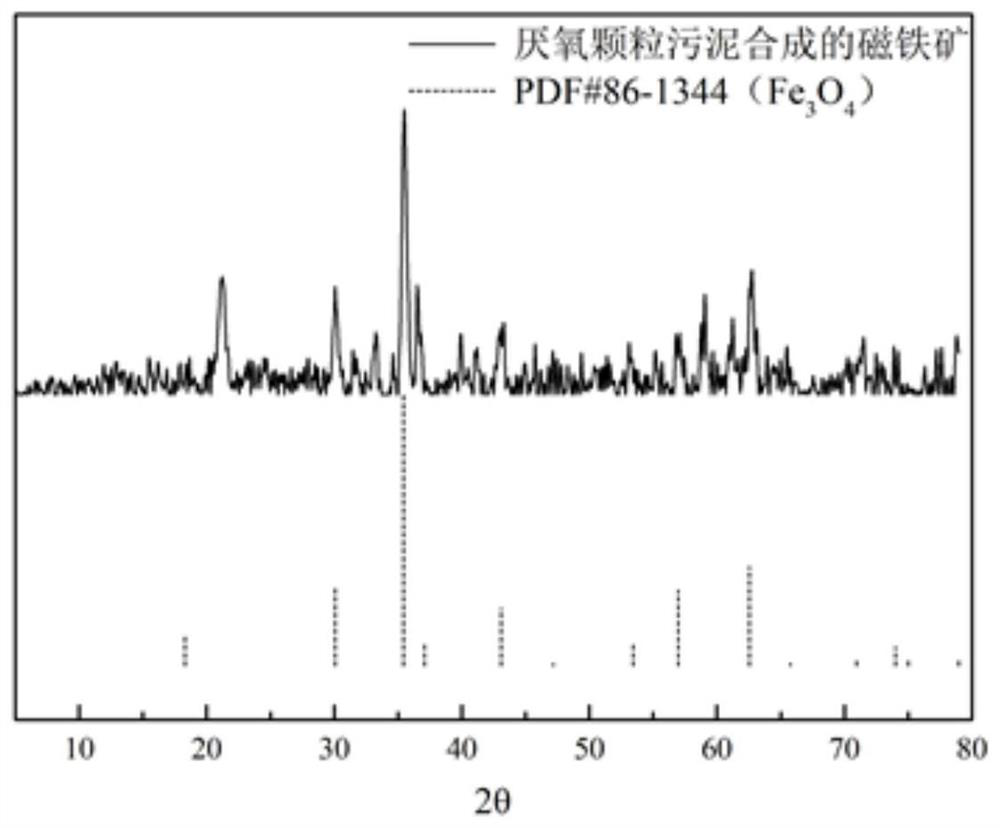

Method used

Image

Examples

Embodiment 1

[0028]The composition of the formulation of trace elements is as follows: NISO4· 6h20 = 500mg / L, MNCL2· 4h20 = 500mg / L, FESO4· 7h20 = 500mg / L, ZNSO4· 7h20 = 100mg / L, H3BO3= 100mg / L, NA2MOO4· 2h20 = 50mg / L, CoCl2· 6h20 = 50mg / L, CUSO4· 5h20 = 5 mg / L.

[0029]The composition for formulated inorganic salt culture is as follows: NH4HCO3= 460mg / l, kh2PO4= 70mg / L, NAHCO3= 1000mg / L, CACL2= 7.5 mg / L, the microelectric solution is 1 mL / L.

[0030]1) Take the anaerobic particle sludge of the sewage treatment plant, cleaned with the above-formulated inorganic salt culture fluid, and then placed in the top and space bottle, then add inorganic salt culture solution, then adding glucose to the inorganic salt culture solution. The anaerobic particle sludge mixture was obtained, allowing the concentration of glucose concentration in anaerobic particulate sludge mixture to 2500 mg / L, so that the sludge concentration was 4 g mlVSS / L.

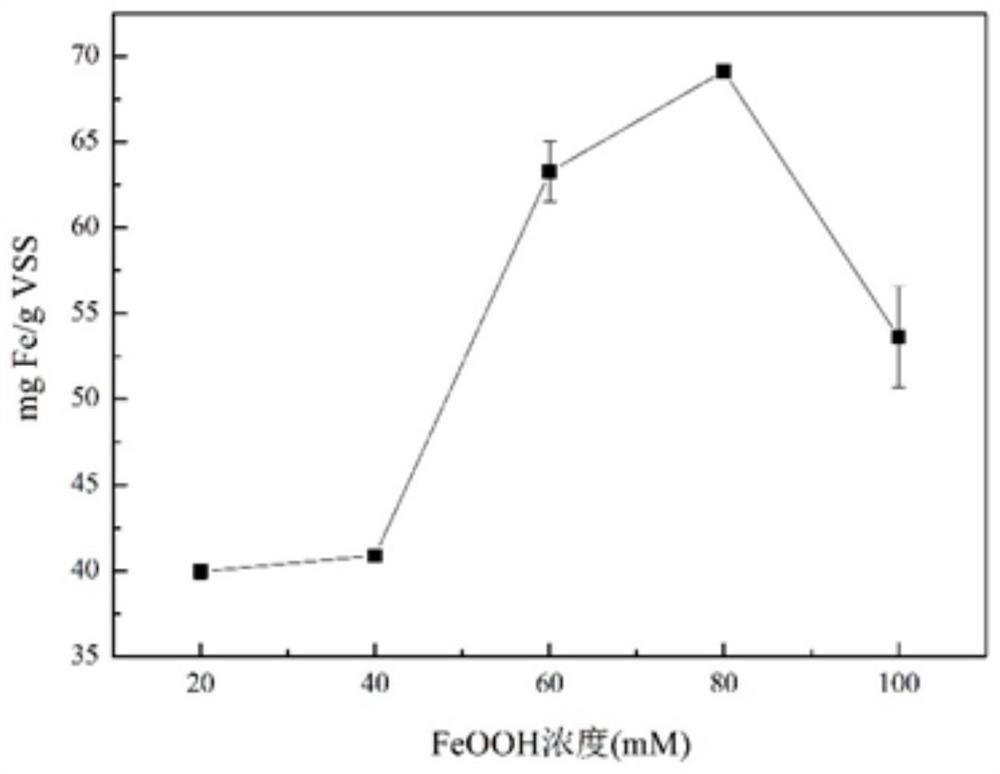

[0031]2) FECL for formulation concentration ...

Embodiment 2

[0038]1) Take the anaerobic particle sludge of the sewage treatment plant, cleaned with the inorganic salt culture fluid formulated by Example 1, and then placed in the top and spaced bottle, then adding the inorganic salt culture, and added to the inorganic salt culture. In the liquid, anaerobic particulate sludge mixture was obtained, and the concentration of the glucose concentration in anaerobic particulate sludge mixture was 2500 mg / L, so that the sludge concentration was 4 g mlVSS / L.

[0039]2) FECL for formulation concentration is 0.4mol / L3· 6h2O solution and NaOH solution having a concentration of 10 mol / L, in FeCl3· 6h2The NaOH solution was slowly added while stirring while stirring, and the resulting precipitate was washed to obtain an amorphous hydroxyl oxide suspension obtained by PH = 7.

[0040]An amorphous hydroxylide iron hydrogen peroxide suspension is added to the anaerobic particulate sludge mixture and the sodium acetate as the electron donate, and the concentr...

Embodiment 3

[0046]1) Take the anaerobic particle sludge of the sewage treatment plant, cleaned with the inorganic salt culture fluid formulated by Example 1, and then placed in the top and spaced bottle, then adding the inorganic salt culture, and added to the inorganic salt culture. In the liquid, anaerobic particulate sludge mixture was obtained, and the concentration of the glucose concentration in anaerobic particulate sludge mixture was 2500 mg / L, so that the sludge concentration was 4 g mlVSS / L.

[0047]2) FECL for formulation concentration is 0.4mol / L3· 6h2O solution and NaOH solution having a concentration of 10 mol / L, in FeCl3· 6h2The NaOH solution was slowly added while stirring while stirring, and the resulting precipitate was washed to obtain an amorphous hydroxyl oxide suspension obtained by PH = 7.

[0048]An amorphous hydroxylide iron oxide suspension and a pyruvate of the electron donor were added to the anaerobic particulate sludge mixture, and the concentration of the hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com