Preparation method of MOF-5/PPy/GO nano material and application of MOF-5/PPy/GO nano material in supercapacitor

A MOF-5, 1. MOF-5 technology, applied in the field of supercapacitors, can solve the problems of limiting the application of MOF-5 derivative materials, poor conductivity, poor cycle stability, etc., to achieve improved capacitance performance and high electrical conductivity , high electrical conductivity and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

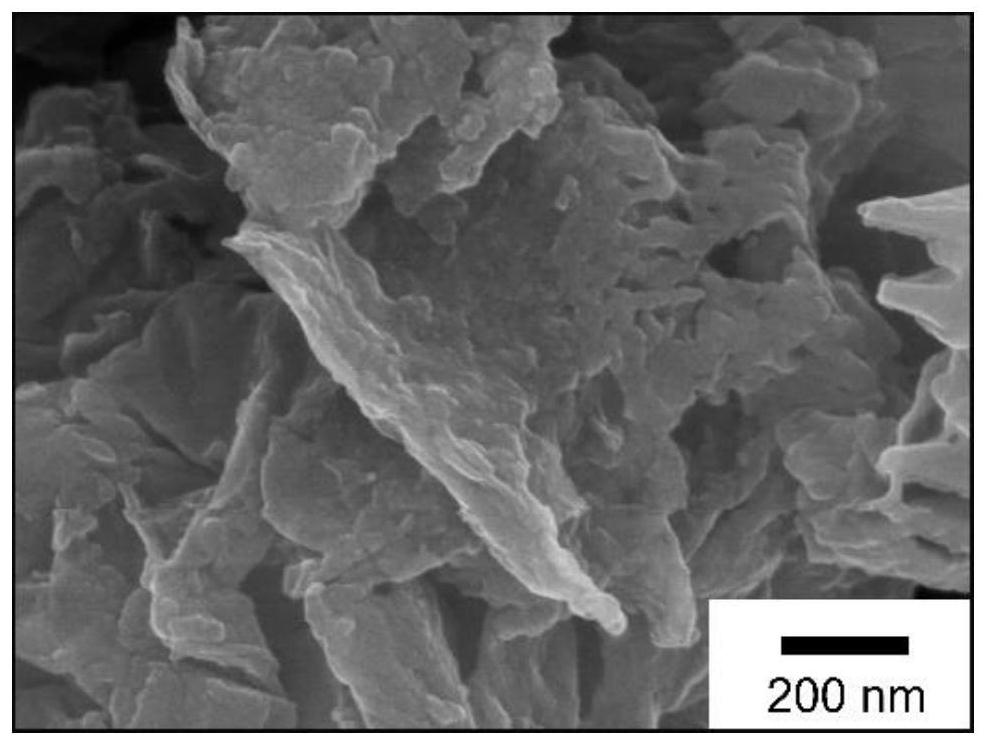

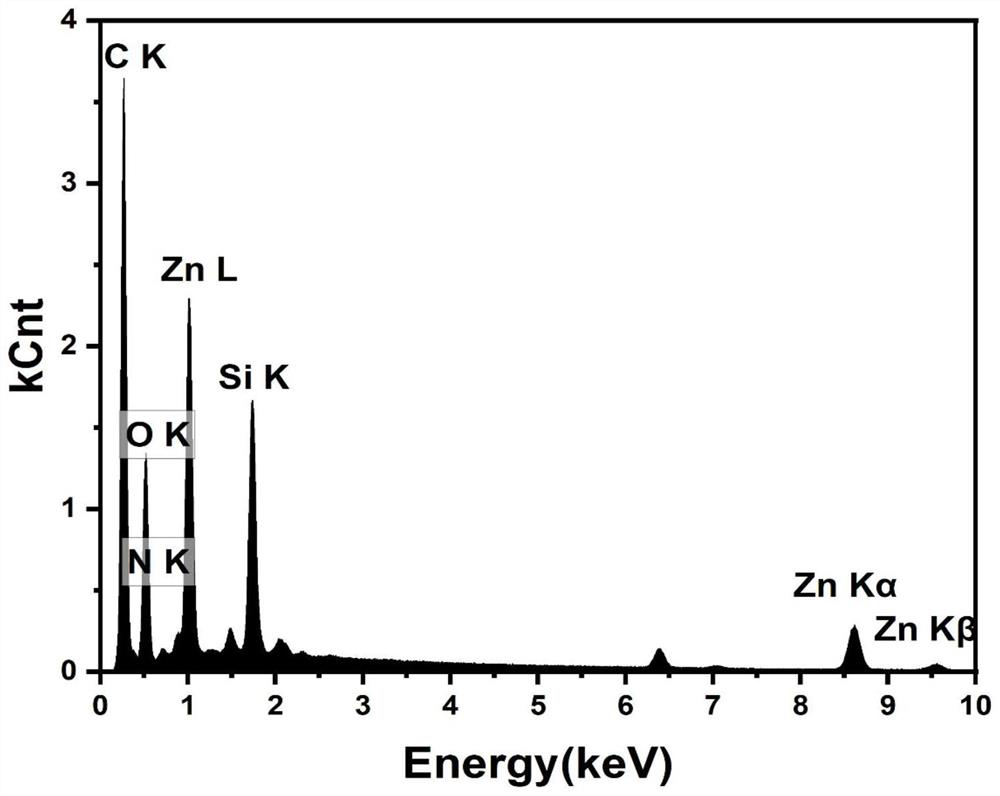

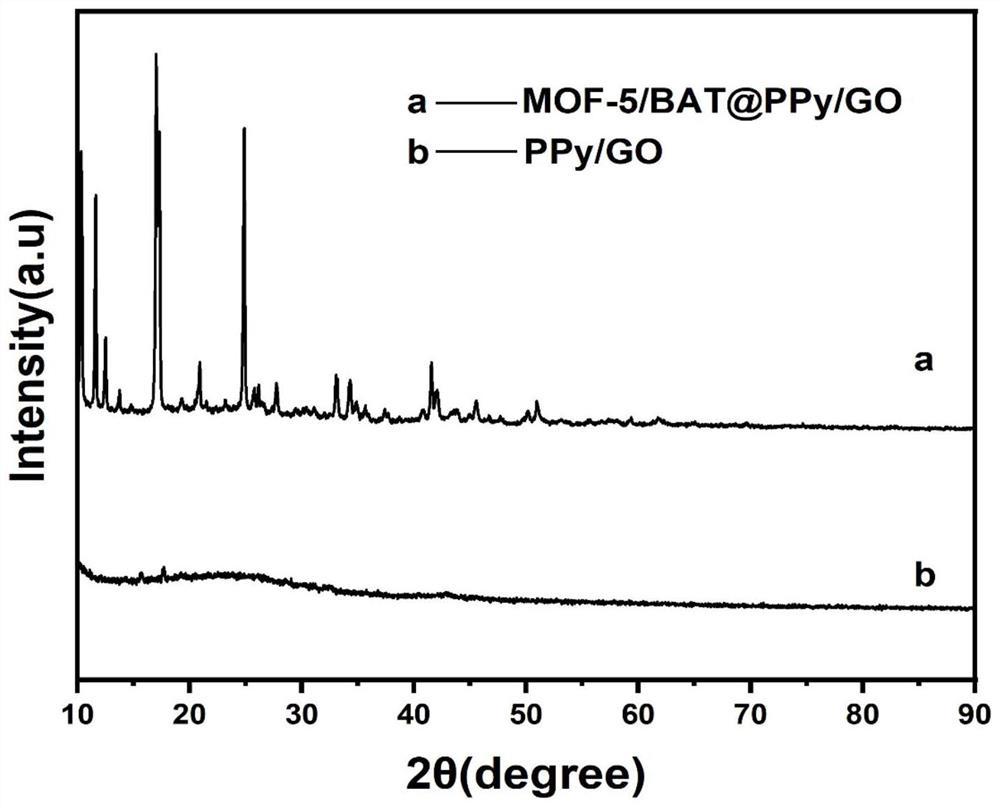

[0032] Embodiment 1MOF-5 / PPy / GO nanometer material

[0033] (1) The preparation method is as follows:

[0034] 1) Preparation of GO nanosheets by Hummers method: 67.5mL of concentrated sulfuric acid, 2.0g of high-purity graphite and 1.6g of NaNO were sequentially added into a three-neck flask 3 , Stir evenly, keep the system temperature below 5°C, slowly and continuously add 9gKMnO to the mixed solution within 1h 4 , then placed in a 36°C water bath to react for 0.5h, after two weeks at room temperature, diluted with 560mL of 60°C water, and added dropwise with H 2 o 2 Until the solution is bright yellow, centrifuge while it is hot (10000rpm), wash to neutrality, and vacuum dry at 50°C to obtain GO nanosheets;

[0035] 2) Preparation of PPy / GO nanosheets: Add 0.2g GO nanosheets to 100mL deionized water, ultrasonically disperse, then add 0.2g pyrrole (Py), add 0.6g FeCl after ultrasonically dispersed 3 ·6H 2 O, continue to sonicate for 0.5h, wash the obtained product with ...

Embodiment 2

[0042] Example 2 Modified electrodes based on MOF-5 / PPy / GO nanomaterials

[0043] (1) The preparation method is as follows:

[0044] 1) Preparation of composite modifier: take 8 mg of the dry MOF-5 / PPy / GO nanomaterial prepared in Example 1, add 1 mg of acetylene black, 1 mg of tetrafluoroethylene and 1 mL of absolute ethanol, and ultrasonically disperse for 30 minutes to obtain a black suspension The turbid liquid is the composite modifier, which is reserved;

[0045] 2) Electrode treatment: ultrasonically wash a 1cm×1.5cm stainless steel sheet with acetone, absolute ethanol and water for 30 minutes, and then dry it for later use;

[0046] 3) Preparation of modified electrode: Use a pipette to pipette 0.125mL of the composite modifier prepared in step 1), drop-coat it on the surface of the stainless steel sheet treated in step 2), and dry it at 60°C for 12h to obtain MOF-5 / PPy / GO modified electrodes.

[0047] (2) Electrochemical performance test

[0048] 1. Research on ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com