A kind of preparation method of multi-branched nano-triangular Pt catalyst functionalized with polyethyleneimine

A polyethylenimine and functionalization technology, which is applied in the field of preparation of multi-branched nano-triangular Pt catalysts, can solve the problems that hinder the commercial development of hydrogen production technology by electrolysis of water, the high price of Pt black catalysts, and low catalytic activity, and achieve Excellent catalytic stability, inhibition of Ostwalder ripening effect, simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

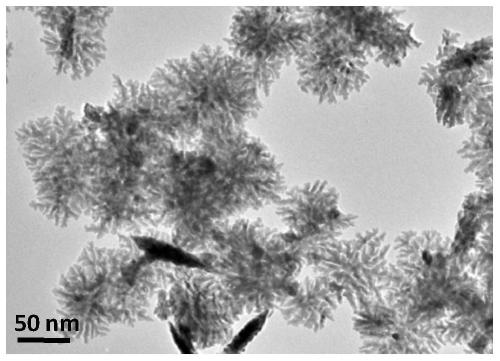

[0023] Mix 5 mL of 0.01 mol / L aqueous solution of potassium chloroplatinite with 5 mL of 0.2 mol / L aqueous solution of polyethyleneimine with a number average molecular weight of 70,000, adjust the pH of the mixture to 8 with 0.1 mol / L hydrochloric acid, and heat to 80°C, add 1mL of hydrazine hydrate aqueous solution with a mass fraction of 85%, let stand at 80°C for 15 hours under normal pressure, and centrifuge and wash the obtained black suspension 3 to 5 times with a high-speed centrifuge at a speed of 10,000 rpm Afterwards, it was dried in a vacuum oven at 60° C. for 12 hours to obtain a multi-branched nanotriangular Pt catalyst functionalized with polyethyleneimine. Depend on figure 1 It can be seen that the obtained sample has a planar multi-branched nano-triangular structure, which greatly improves the utilization rate of the noble metal Pt.

Embodiment 2

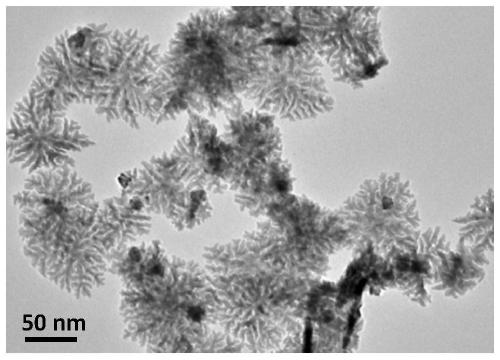

[0025] Mix 5 mL of 0.01 mol / L aqueous solution of potassium chloroplatinite with 5 mL of 0.3 mol / L aqueous solution of polyethyleneimine with a number average molecular weight of 70,000, adjust the pH of the mixture to 8 with 0.1 mol / L hydrochloric acid, and heat to 80°C, add 1mL of hydrazine hydrate aqueous solution with a mass fraction of 85%, let stand at 80°C for 15 hours under normal pressure, and centrifuge and wash the obtained black suspension 3 to 5 times with a high-speed centrifuge at a speed of 10,000 rpm Afterwards, dry in 60 ℃ of vacuum ovens for 12 hours, obtain polyethylenimine functionalized multi-branched nano-triangular Pt catalyst (see figure 2 ).

Embodiment 3

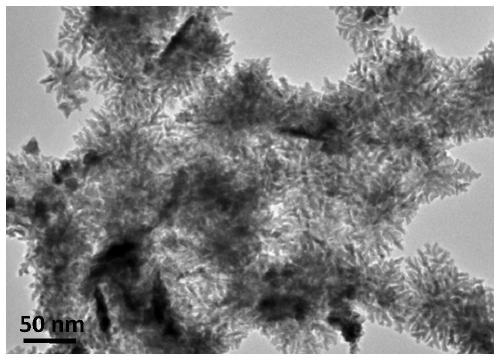

[0027] Mix 5mL of 0.01mol / L aqueous solution of potassium chloroplatinite with 5mL of 0.2mol / L aqueous solution of polyethyleneimine with a number average molecular weight of 70000, adjust the pH of the mixture to 10 with 0.1mol / L hydrochloric acid, and heat to 80°C, add 1mL of hydrazine hydrate aqueous solution with a mass fraction of 85%, let stand at 80°C for 15 hours under normal pressure, and centrifuge and wash the obtained black suspension 3 to 5 times with a high-speed centrifuge at a speed of 10,000 rpm Afterwards, dry in 60 ℃ of vacuum ovens for 12 hours, obtain polyethylenimine functionalized multi-branched nano-triangular Pt catalyst (see image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com