Antibacterial, mildew-proof, antistatic and yellowing-resistant TPU

A anti-yellowing and anti-static technology applied to TPU. It can solve the problems of reducing the service life of TPU and affecting the yellowing resistance of TPU

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

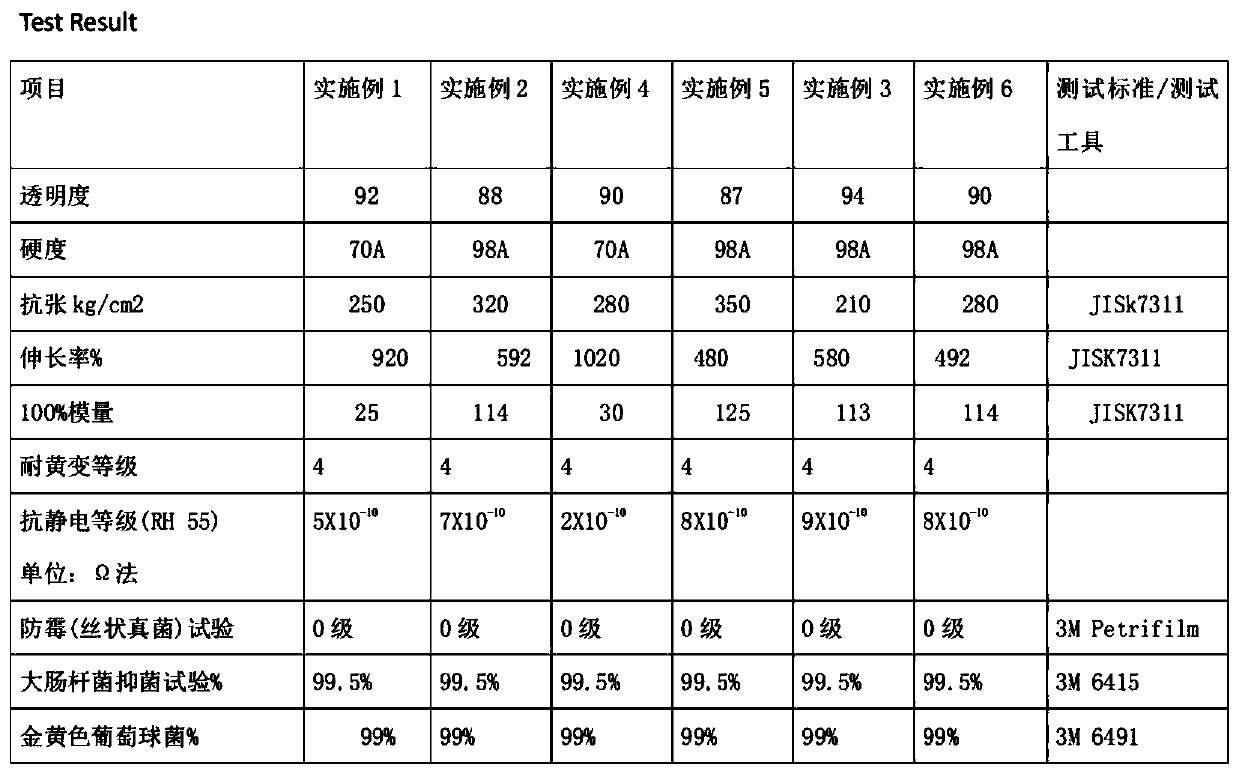

Image

Examples

Embodiment 1

[0032] Step 1: by weight component, get 72 parts of PTMEG type polyether type glycols, 1 part of cetyltrimethylammonium chloride, 0.6 part of nanometer zinc oxide, then the cetyltrimethylammonium of formula quantity Put both ammonium chloride and nano-zinc oxide into PTMEG type polyether glycol, stir and mix, and let it stand for at least 12 hours to fully infiltrate cetyltrimethylammonium chloride and nano-zinc oxide.

[0033] Step 2: Take 4 parts of 1,4-butanediol and 0.4 parts of ethylenediamine and put them into the product obtained in step 1, and then take 20 parts of isocyanate and put them into the mixture, so that the isocyanate index is 1.

[0034] Step 3: Mix 0.5 part of antioxidant and 0.5 part of anti-UV agent with the product obtained in step 2.

[0035] Step 4: put the product obtained in step 3 into a twin-screw machine, and set the screw temperature to 150 degrees.

[0036] Step 5: Put the granules extruded in step 4 into water at 20 degrees to complete granul...

Embodiment 2

[0038] Step 1: by weight component, get 50 parts of PTMEG type polyether type glycols, 1.2 parts of cetyl trimethyl ammonium chloride, 0.8 part of nano-zinc oxide, then the cetyl trimethyl ammonium Put both ammonium chloride and nano-zinc oxide into PTMEG type polyether glycol, stir and mix, and let it stand for at least 12 hours to fully infiltrate cetyltrimethylammonium chloride and nano-zinc oxide.

[0039] Step 2: Take 9 parts of 1,4-butanediol and 1 part of ethylenediamine and put them into the product obtained in step 1, and then take 37 parts of isocyanate and put them into the mixture, so that the isocyanate index is 1.

[0040] Step 3: Mix 0.5 part of antioxidant and 0.5 part of anti-UV agent with the product obtained in step 2.

[0041] Step 4: put the product obtained in step 3 into a twin-screw machine, and set the screw temperature to 150 degrees.

[0042] Step 5: Put the granules extruded in step 4 into water at 20 degrees to complete granulation.

Embodiment 3

[0044] Step 1: by weight component, get 50 parts of PPG type polyether type glycols, 1.2 parts of cetyltrimethylammonium chloride, 0.8 part of nano-zinc oxide, then the cetyltrimethylammonium Put both ammonium chloride and nano-zinc oxide into PPG type polyether glycol, stir and mix, and let it stand for at least 12 hours to fully infiltrate cetyltrimethylammonium chloride and nano-zinc oxide.

[0045] Step 2: Take 9 parts of 1,4-butanediol and 1 part of ethylenediamine and put them into the product obtained in step 1, and then take 20 parts of isocyanate and put them into the mixture, so that the isocyanate index is 1.

[0046] Step 3: Mix 0.5 part of antioxidant and 0.5 part of anti-UV agent with the product obtained in step 2.

[0047] Step 4: put the product obtained in step 3 into a twin-screw machine, and set the screw temperature to 150 degrees.

[0048] Step 5: Put the granules extruded in step 4 into water at 20 degrees to complete granulation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com