A preparation method of high-quality vanadium-titanium pellets with low energy consumption based on high-pressure roller mill pretreatment

A technology of high-pressure roller milling and pelletizing, which is applied in the production of pellets and the preparation of high-quality vanadium-titanium pellets with low energy consumption. It can solve the problems of affecting the oxidation reaction rate, low pellet consolidation strength, and poor pellet oxidation effect. problem, achieve the effect of promoting recrystallization connection, improving strength and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

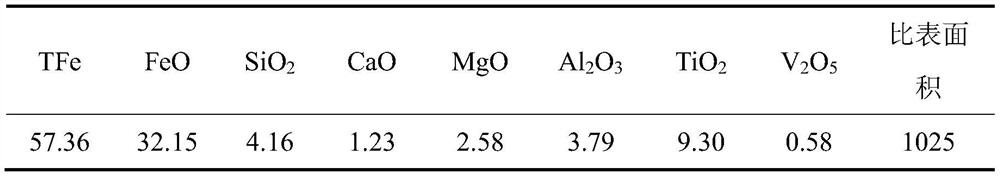

Embodiment 1

[0039] Adopt the vanadium-titanium magnetite of table 1, with it under the condition of pressure 2.5MPa, iron concentrate moisture 7.5% high-pressure roller mill, the specific surface area relative change η of vanadium-titanium magnetite concentrate after roller milling S 0.23, the increase ratio of particle crack rate ΔL 5%; after roller milling, the water pressure is pressurized to 1.2MPa through the pipeline booster pump during the pelletizing process, and the water is dispersed by compressed air to form a particle size of 20-30μm The water mist beads within the range are added to the growing area of the pelletizing disc to make pellets, and the proportion of particle size 13-15mm reaches 88%; the adjusted material height is 180mm×(1+0.23 2 )=190mm, machine speed 2.5 / (1+0.23 2 )=2.37m / min, adjust the preheating temperature 970-0.23×80-0.05×120=946°C, and the calcination temperature 1275-0.23×100=1252°C. After roasting, the pellet oxidation rate is 97%, the residual FeO c...

Embodiment 2

[0041] Adopt the vanadium-titanium magnetite of table 1, with it under the condition of pressure 3MPa, iron concentrate moisture 7.0% high-pressure roller mill, the specific surface area relative change η of vanadium-titanium magnetite concentrate after roller milling S 0.30, the increase ratio of particle crack rate ΔL 7%; after roller milling, pressurize the water pressure to 1MPa through the pipeline booster pump, and disperse the water through compressed air to form water mist with a particle size in the range of 30-40μm Beads are added to the growing area of the pelletizing disk, and it is made into pellets, and the proportion of particle size 13-15mm reaches 90%; the adjustment material height is 180mm×(1+0.3 2 )=196mm, machine speed 2.5 / (1+0.3 2 )=2.29m / min, adjust the preheating temperature 970-0.3×80-0.07×120=938°C, and the calcination temperature 1275-0.3×100=1245°C. After roasting, the pellet oxidation rate is 98%, the residual FeO content is 0.6%, the pellet str...

Embodiment 3

[0043] Adopt the vanadium-titanium magnetite of table 1, with it under the condition of pressure 2.75MPa, iron concentrate moisture 6.5% high-pressure roller mill, the specific surface area relative change η of vanadium-titanium magnetite concentrate after roller milling S 0.25, the increase ratio of particle crack rate ΔL 4%; after roller milling, the water pressure is pressurized to 1.1MPa through the pipeline booster pump during the pelletizing process, and the water is dispersed by compressed air to form a particle size of 30-40μm The water mist beads within the range are added to the growing area of the pelletizing disc to make pellets, and the proportion of particle size 13-15mm reaches 87%; the adjustment material height is 180mm×(1+0.25 2 )=191mm, machine speed 2.5 / (1+0.25 2 )=2.35m / min, adjust the preheating temperature 970-0.25×80-0.04×120=945°C, and the calcination temperature 1275-0.25×100=1250°C. After roasting, the pellet oxidation rate is 97%, the residual Fe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com