Micro-water monitoring and processing system for GIS transformer substation

A treatment system and substation technology, which is applied in the detection and treatment of micro-water content of sulfur hexafluoride gas, can solve the problems of non-recovery of replacement gas, flashover, and time-consuming detection and processing, and achieve convenient installation and accurate detection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

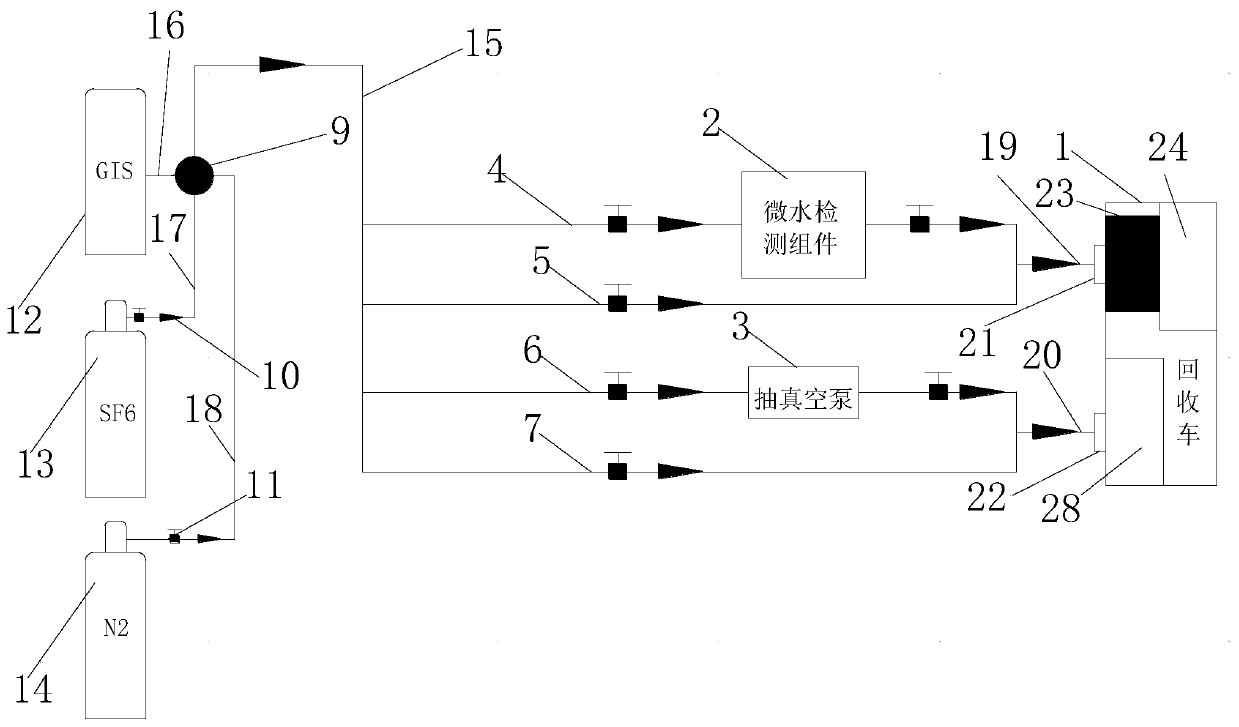

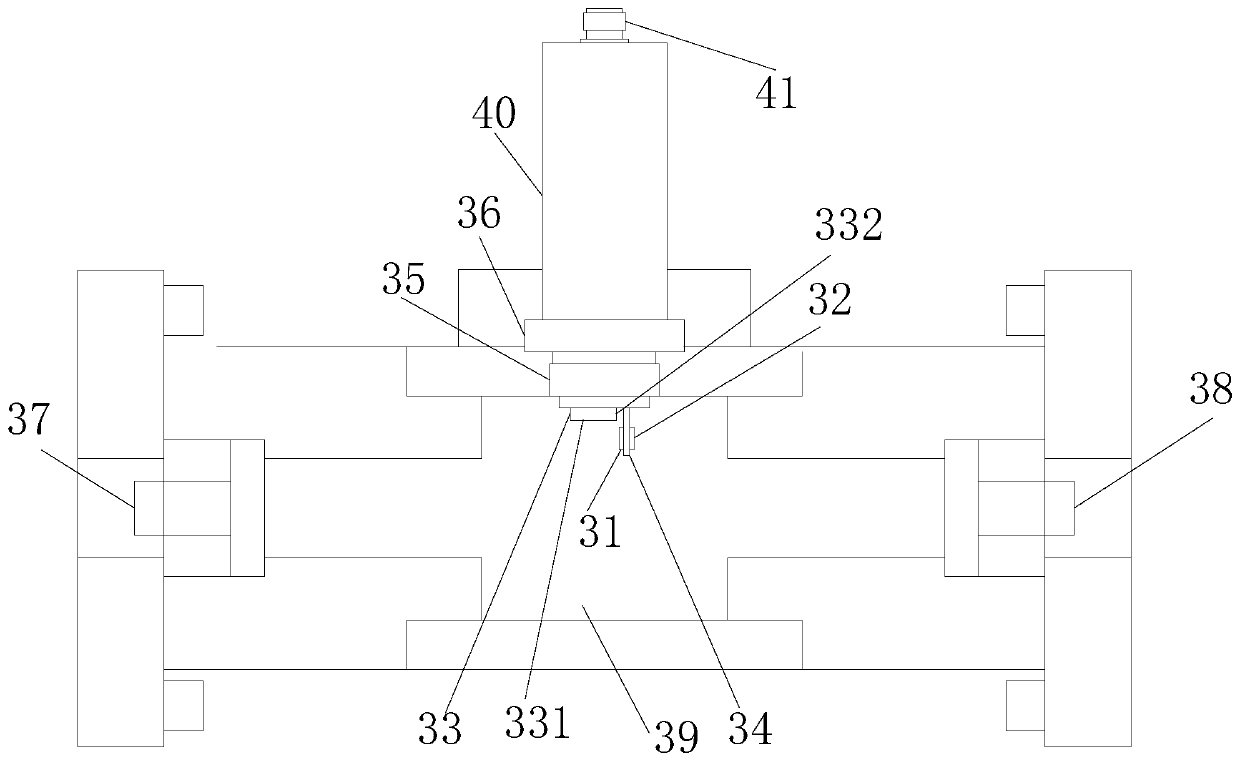

[0037] Such as Figure 1~4 As shown, it shows the specific implementation of the present invention, as shown in the figure, the present invention is used in the micro-water monitoring and processing system of GIS substation, including the four-way connection with the GIS equipment air chamber interface 16 of the GIS equipment air chamber 12 Valve 9; the second outlet pipeline 93 of the four-way valve 9 is connected to the gas chamber interface of the GIS equipment through the second outlet air joint 94; the four-way valve 9 is also provided with a first outlet pipeline 91, a second Three outlet pipelines 96 and a fourth outlet pipeline 98;

[0038] The first outlet pipeline, the third outlet pipeline and the fourth outlet pipeline are respectively connected with a discharge main pipeline 15, a sulfur hexafluoride gas charging pipeline 17 and a nitrogen gas charging pipeline 18;

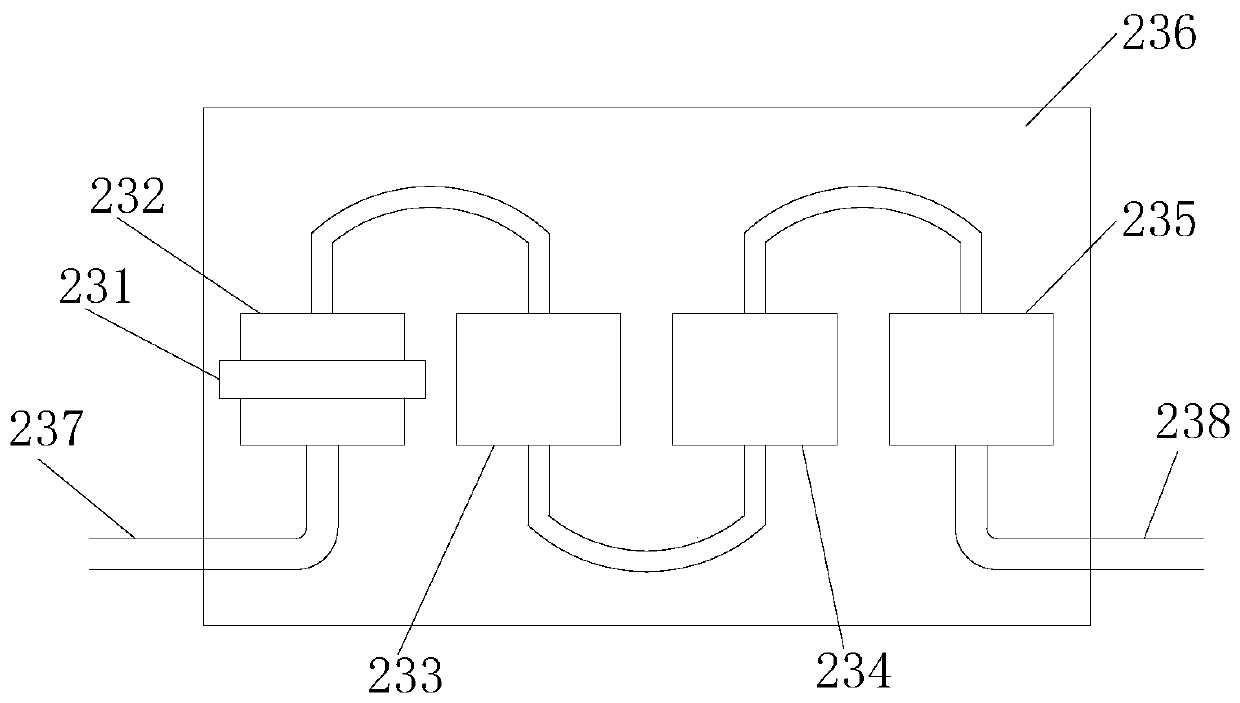

[0039] There are four branches connected in parallel on the main discharge main line 15, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com