Heat exchanger and manufacturing method thereof

A manufacturing method and heat exchanger technology, applied in heat exchange equipment, lighting and heating equipment, tubular elements, etc., can solve the problems of low heat exchange efficiency, achieve the effects of improving heat exchange efficiency, increasing disturbance, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

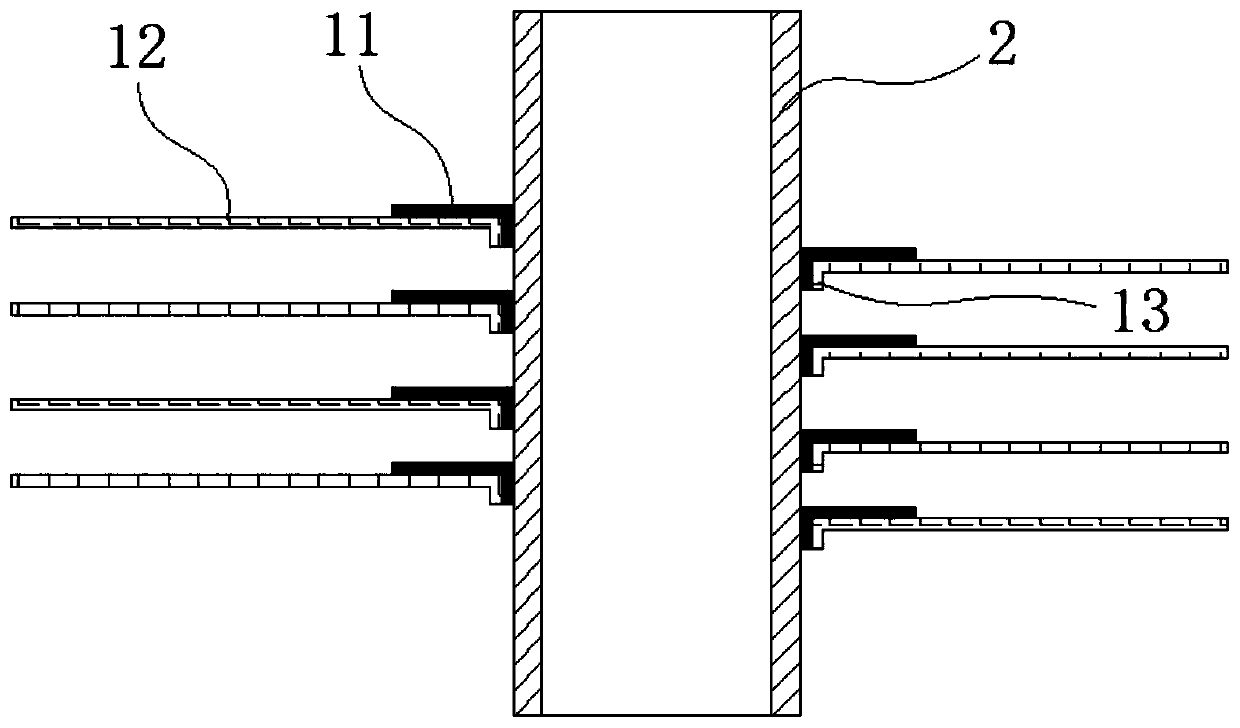

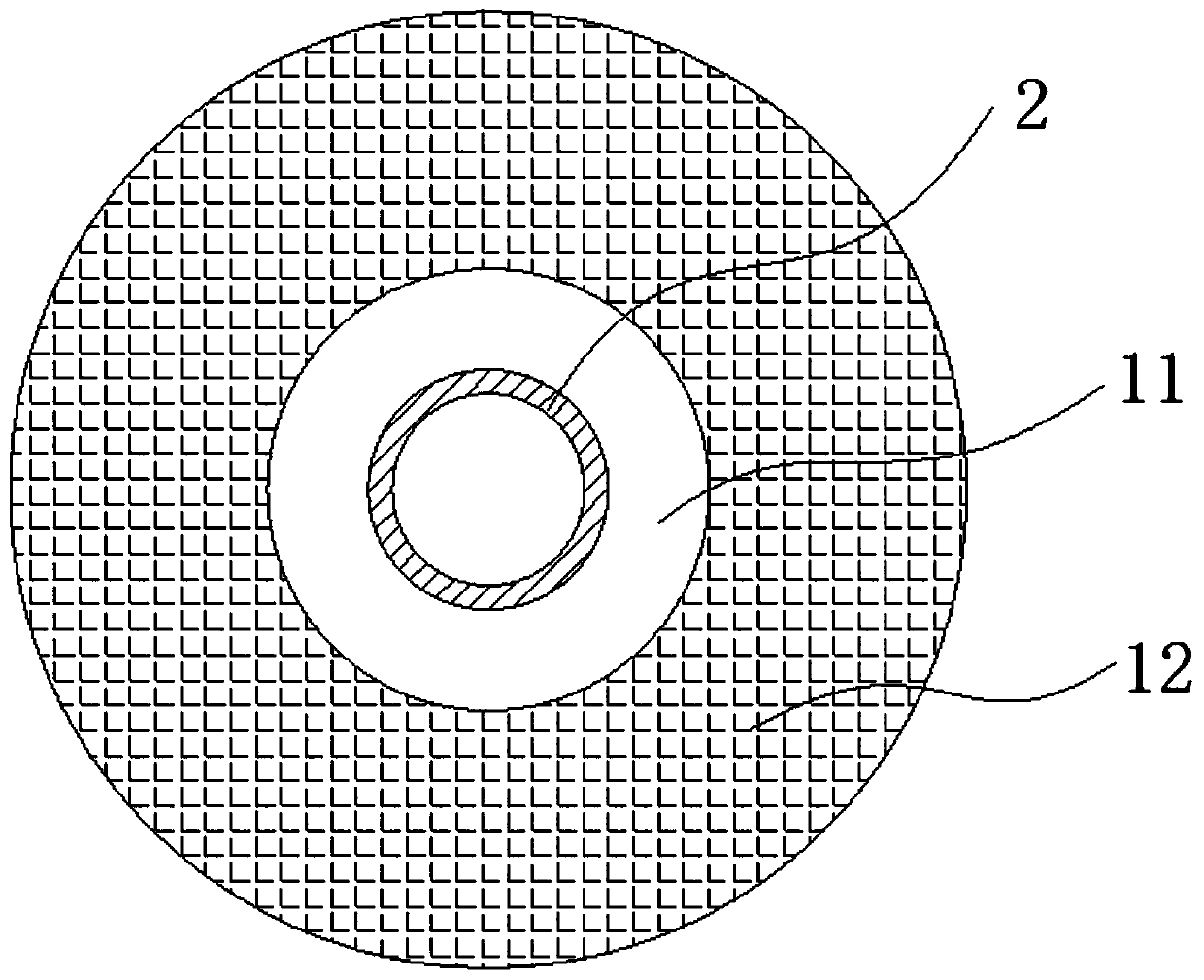

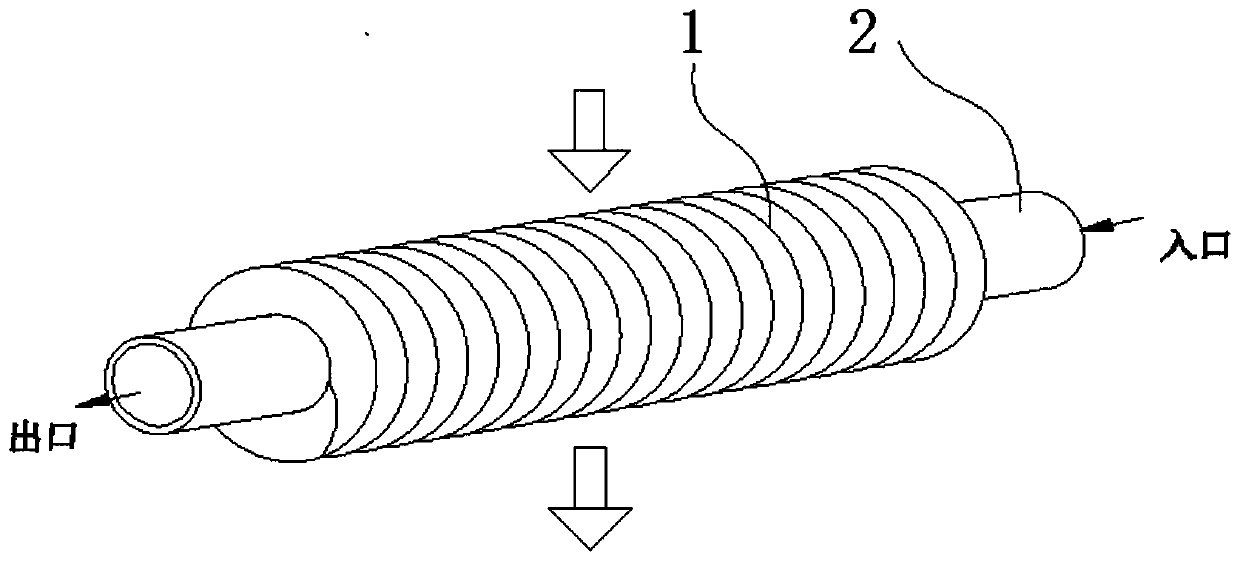

[0029] Such as Figure 1 to Figure 4 As shown, a heat exchanger includes a heat exchange tube 2, and a spiral coil 1 is wound on the outer wall of the heat exchange tube 2; the coil 1 includes a metal sheet 11 and a wire mesh 12, and the The wire mesh 12 is fixed on the surface of the metal sheet 11. The wire mesh 12 greatly increases the contact area of fluids such as air, and can also increase the disturbance when fluids such as air flow through, which will significantly enhance the heat exchange efficiency.

[0030] In this embodiment, the wire mesh 12 is fixed on the surface of the thin metal plate 11 by diffusion welding. The wires of the wire mesh 12 are connected to each other by diffusion welding to form an integral body; the wires of the wire mesh 12 and the wire mesh 12 and the thin metal plate 11 are formed into a whole by diffusion welding At the same time, it is connected with the outer wall of the heat exchange tube 2 by an interference fit, which can ensure ...

Embodiment 2

[0036] This embodiment provides a method for manufacturing a heat exchanger, comprising the following steps:

[0037] S1. According to the design and performance requirements of the heat exchanger, determine the overall structure and size of the heat exchanger, including the diameter and length of the heat exchange tube 2, as well as the outer diameter, spacing and number of winding turns of the winding sheet 1;

[0038]S2. Determine the materials of the wire mesh 12 and the smooth metal sheet 11 according to the requirements of the heat exchanger. The wire mesh 12 and the metal sheet 11 generally use the same type of material, and the materials can be copper or copper alloy, aluminum or aluminum alloy, Steel or stainless steel, etc.;

[0039] S3. Determine the shape, size and thickness of the wire mesh 12 and the metal sheet 11 according to the outer diameter of the winding sheet 1, the spacing and the number of winding turns, and the wire mesh 12 and the metal sheet 11 are e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com