Lining assembly and reaction chamber

A technology of lining components and reaction chambers, which is applied in the fields of electrical components, semiconductor/solid-state device manufacturing, discharge tubes, etc., can solve problems such as high product cost, complex structure, and eccentric etching results, so as to reduce product production costs, The effect of improving angular uniformity and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order for those skilled in the art to better understand the technical solution of the present invention, the lining assembly and the reaction chamber provided by the present invention will be described in detail below with reference to the accompanying drawings.

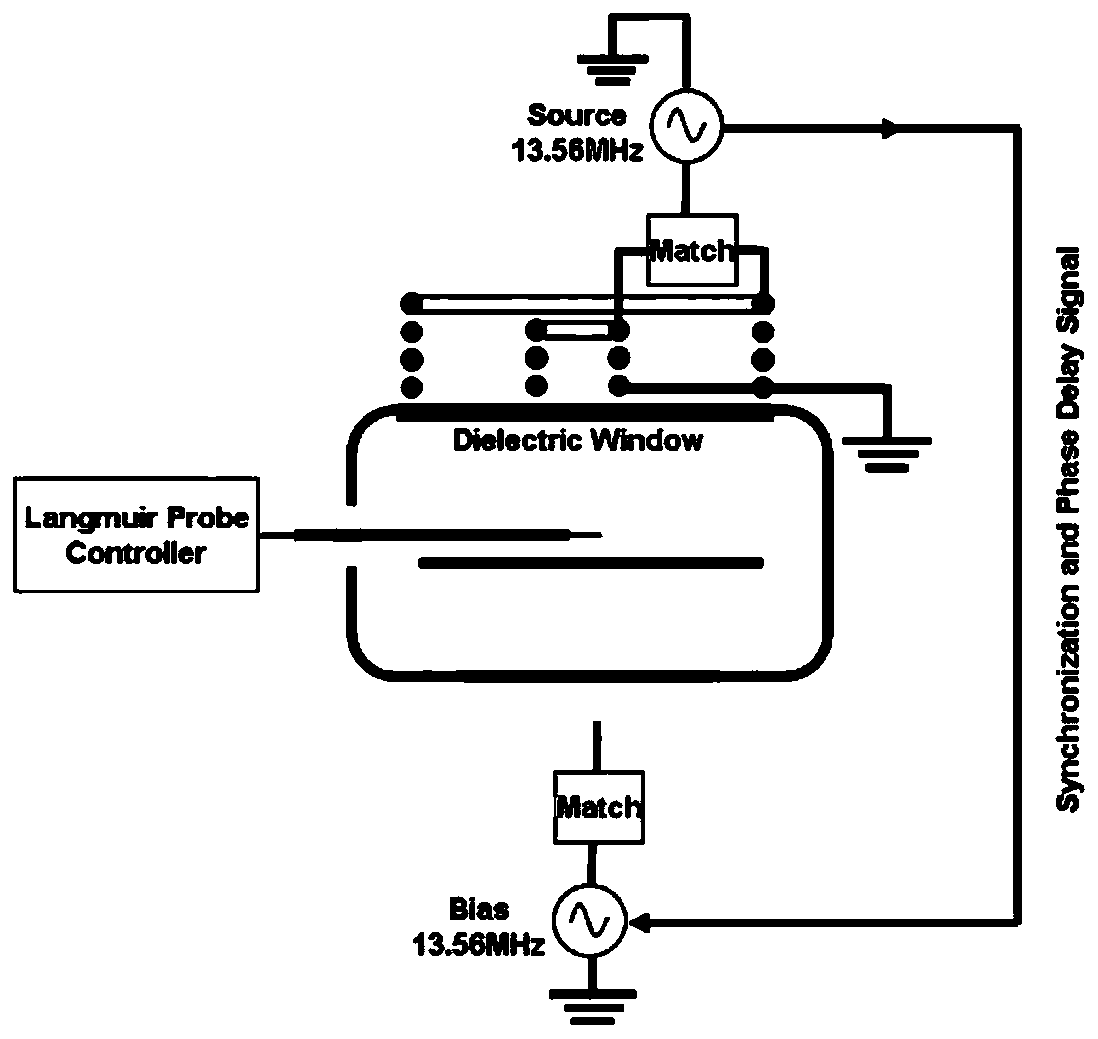

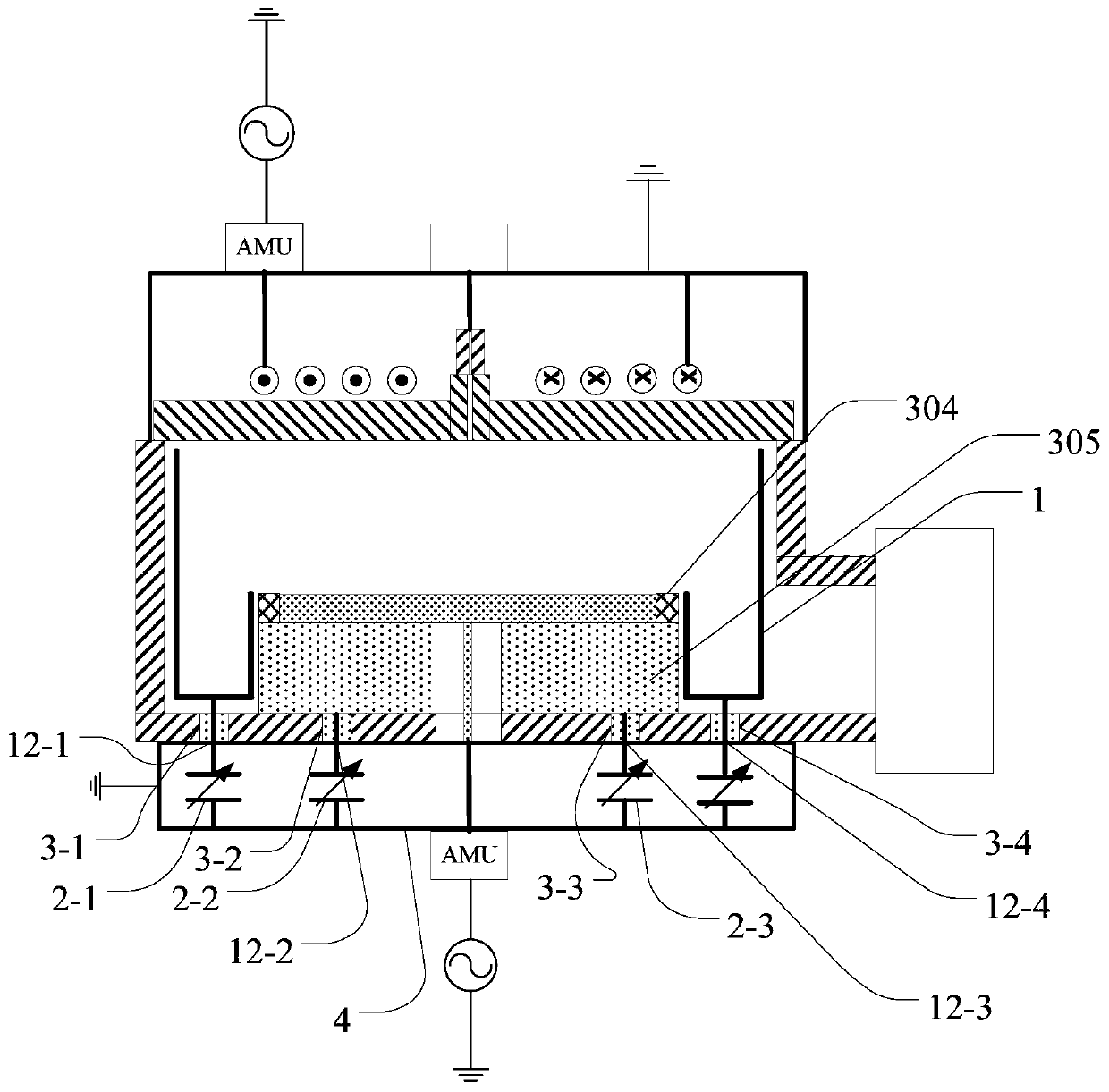

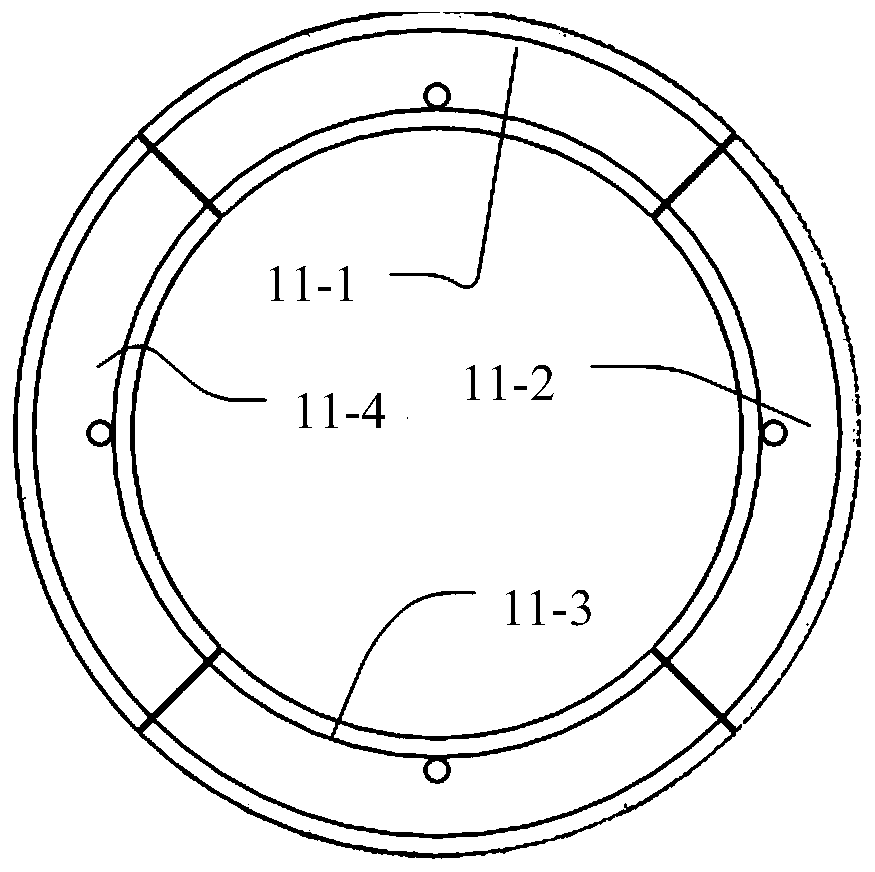

[0027] figure 2 It is a schematic structural view of a reaction chamber provided by an embodiment of the present invention, and FIG. 3 is a schematic structural view of a liner used in a liner assembly provided by an embodiment of the present invention. please combine figure 2 3, the first embodiment of the present invention provides a liner assembly, including a liner 1 and a plurality of adjustment units 2, wherein the liner 1 is used to surround the inside of the side wall of the reaction chamber, and the liner 1 includes A plurality of sub-liners 11 (11-1, 11-2, 11-3, 11-4) corresponding to a plurality of adjustment units 2 (2-1, 2-2, 2-3, 2-4), A plurality of sub-liners 11 (11-1, 11-2, 11-3, 11-4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com