Super-hydrophobic aluminum alloy filter screen as well as preparation method and application thereof

A super-hydrophobic, aluminum alloy technology, applied in comprehensive cross-fields, can solve the problems of poor oil-water separation effect, complex modification process, and difficulty in special micro-nano structure, and achieve high oil-water separation efficiency and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

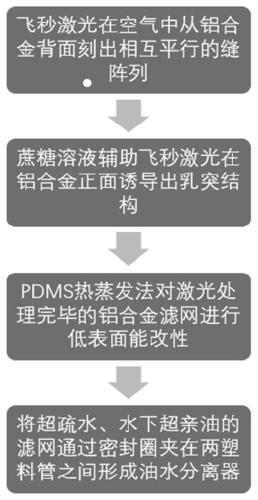

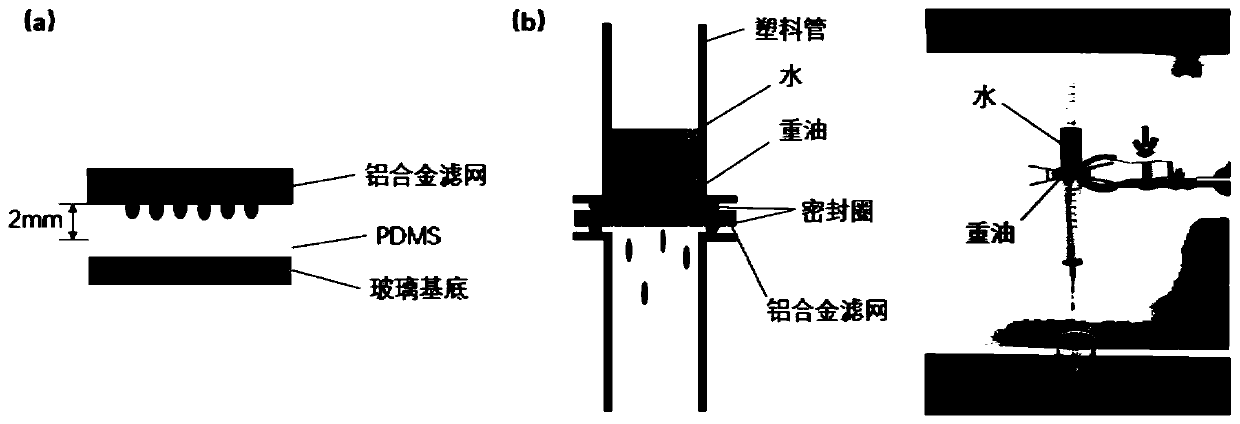

[0034] This embodiment is a kind of embodiment of the preparation method of superhydrophobic aluminum alloy filter screen of the present invention, and this preparation method comprises the following steps:

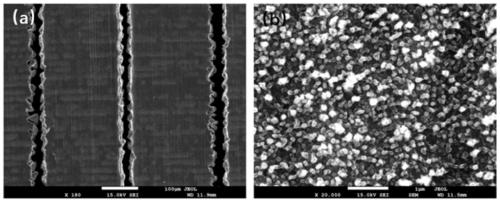

[0035] (1) Use acetone, ethanol and water to ultrasonically clean each aluminum alloy for 3-5 minutes, and then use a focused femtosecond laser to engrave parallel seams on the back of the aluminum alloy in the air to form a seam array (specifically as figure 2 As shown in (a), the slit width is maintained at 35 μm, the slit spacing is 200-350 μm, the thickness of the aluminum alloy is 100 μm, and the output center wavelength of the amplifier laser used (manufacturer: Coherent, USA, model: Legend) is 800nm , the pulse width is 100fs, the repetition rate is 1kHz, the femtosecond laser is focused through a lens with a focal length of 15cm, and the spot size after focusing is about 40μm;

[0036] (2) Submerge the aluminum alloy treated in step (1) in a sucrose solution, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Oil-water separation efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com