Waste heat utilization and circulating refrigeration device of mixed refrigerant compressor unit

A technology of mixed refrigerant and compressor unit, which is applied in refrigeration and liquefaction, separation of cold treatment, lighting and heating equipment, etc. It can solve problems such as energy loss and waste of resources, reduce water content, save industrial costs, and improve the level of technical equipment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0051] Take the 1 million m3 / day LNG liquefaction unit of an LNG liquefaction plant as an example:

[0052] serial number equipment items amount) Total power (kW) 1 Raw material gas compressor unit 1 2000 2 Original mixed refrigerant compressor unit 1 13500 3 Original dehydration molecular sieve heater 1 600 4 Added lithium bromide unit 1 10 5 Added hot water circulation pump 2 45 6 Add chilled water circulation pump 2 70

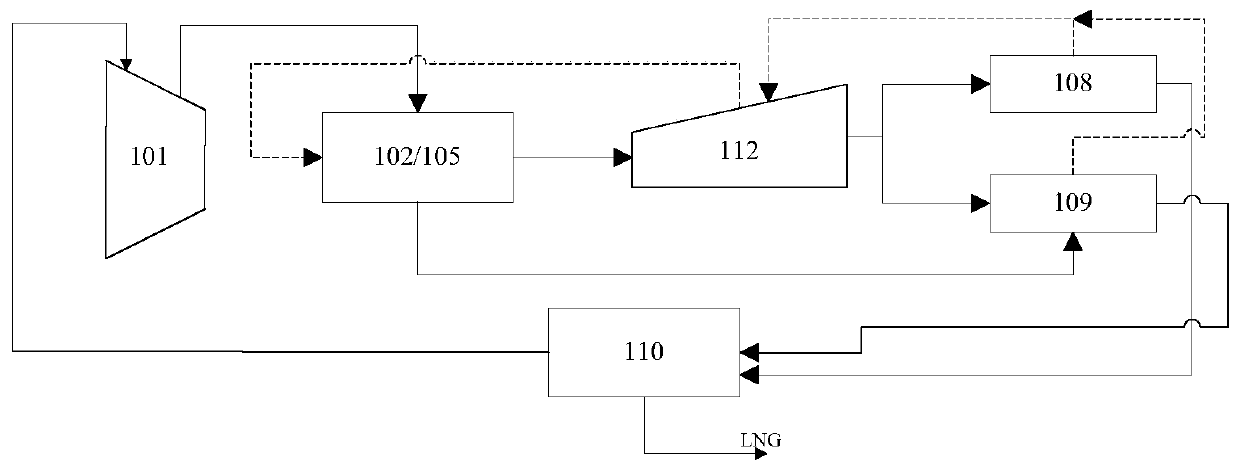

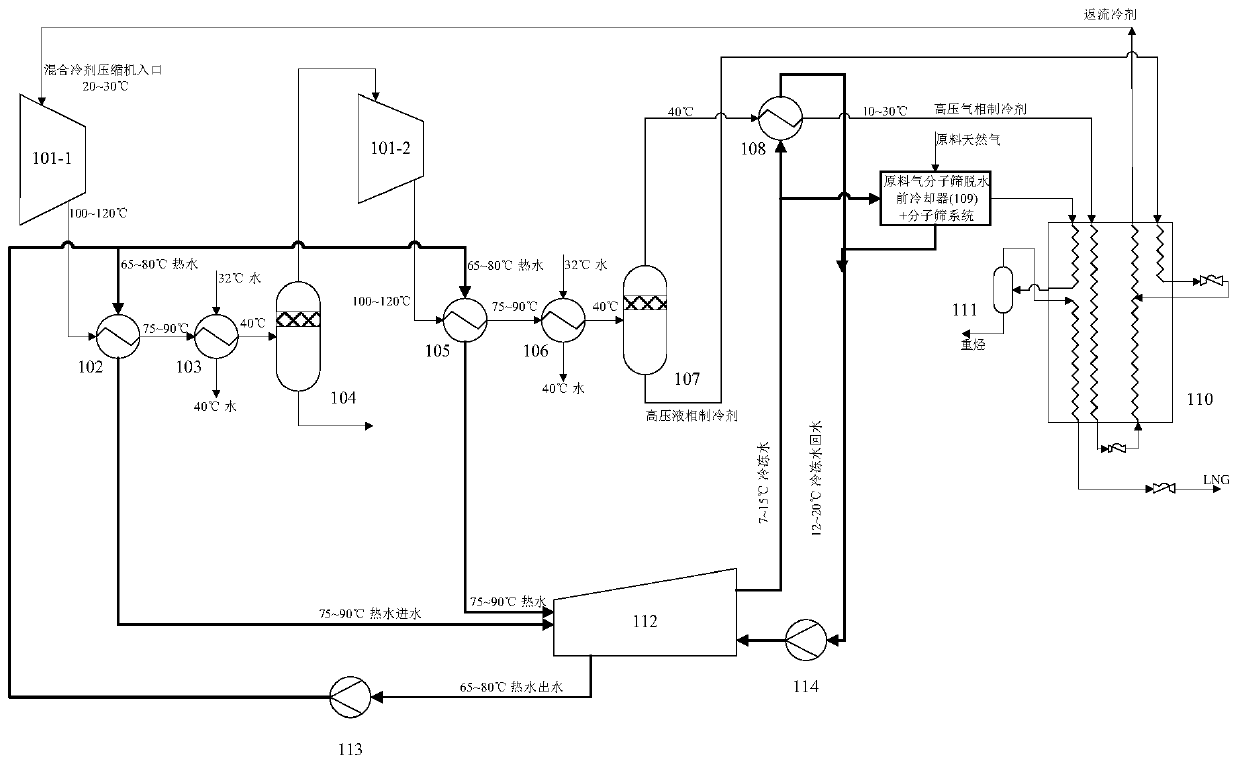

[0053] Use Aspen software to carry out numerical simulation calculation and heat exchanger selection calculation on the thermal data of the high-temperature process gas waste heat of the mixed refrigerant compressor unit, such as figure 1 As shown, the total amount of waste heat that can be used after the system is balanced and the specific parameters of each module are obtained through analysis and calculation.

[0054] The 1 million m3 / day LNG liquefaction plant can save 625-850kw of ener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com