Smelting furnace with tin concentrate continuous crude tin smelting and continuous slag fuming functions and smelting method

A tin concentrate and smelting furnace technology, which is applied in the field of non-ferrous metal metallurgical equipment, can solve the problems of long time consumption, many production links, and complicated processes, and achieve the effects of small fluctuations in SO2 concentration, improved product quality, and simple raw material preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

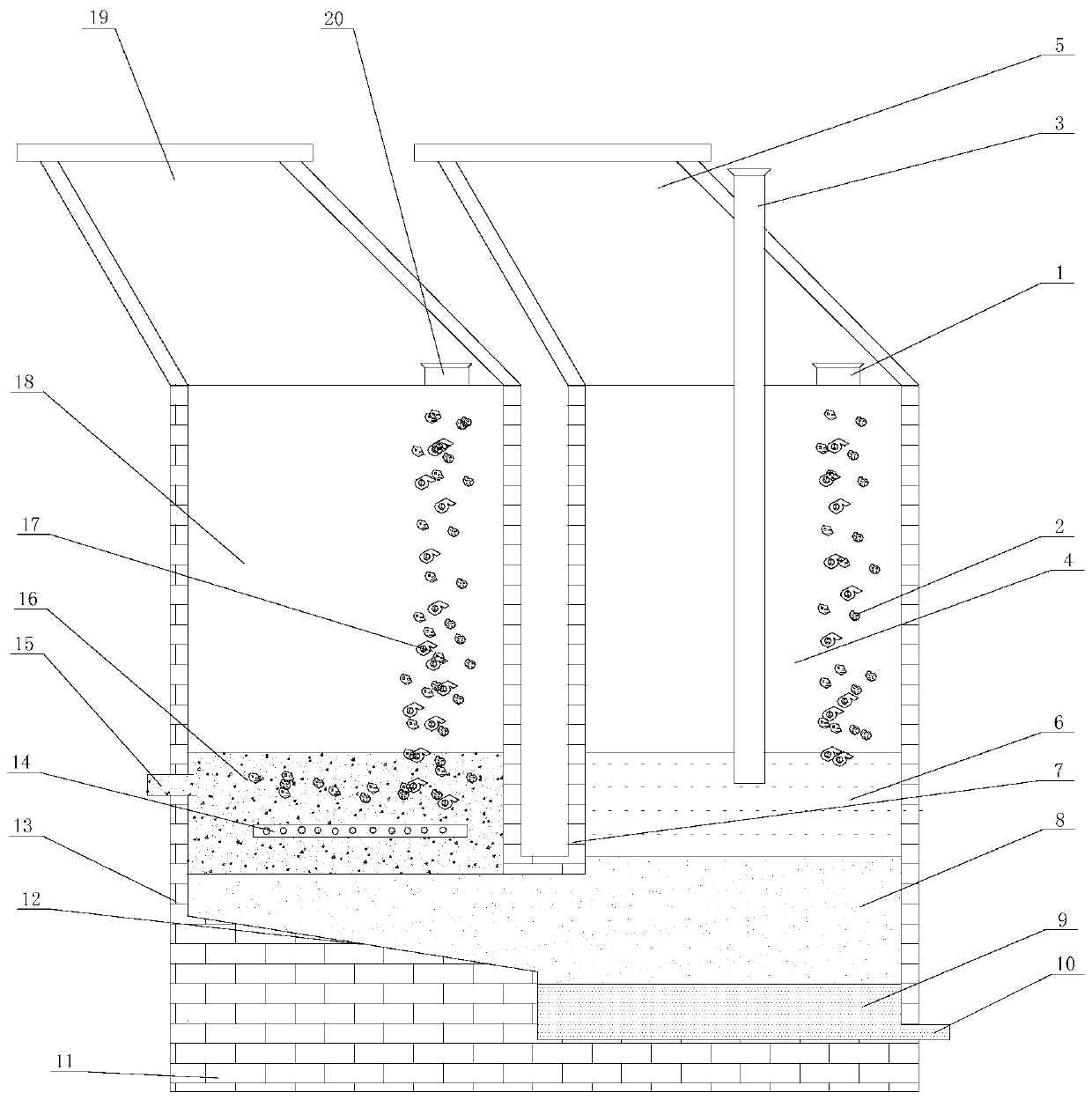

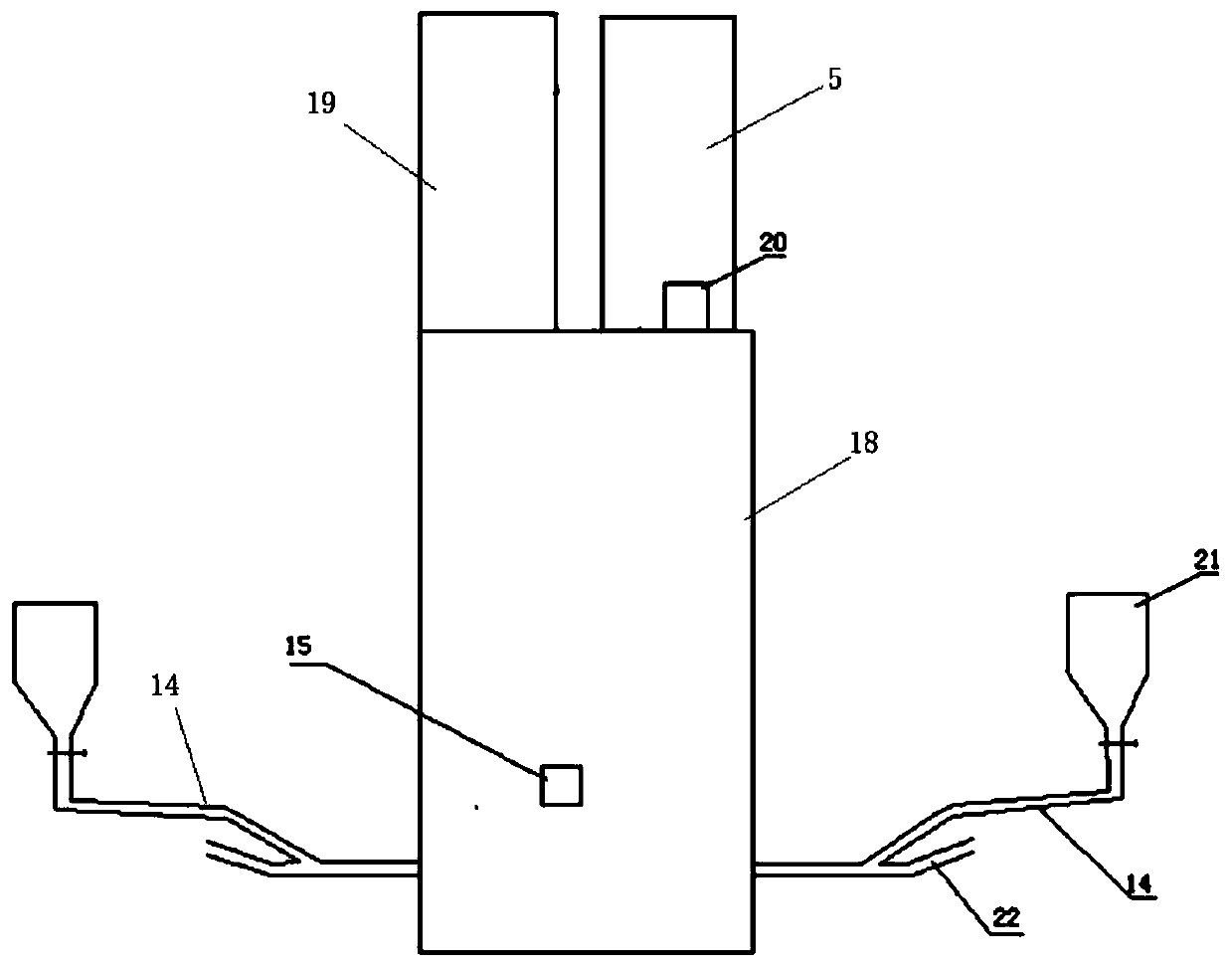

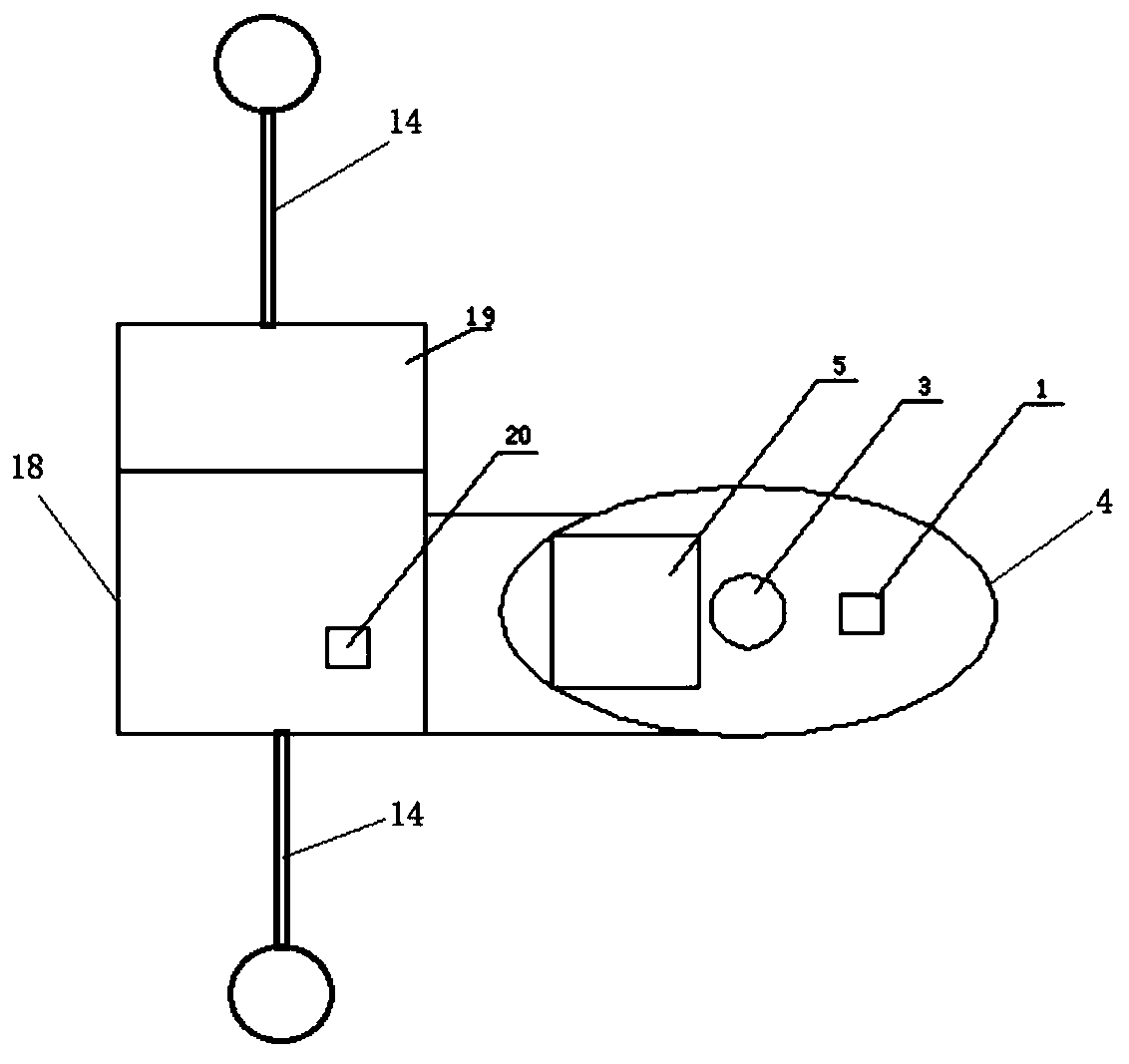

[0023] Such as figure 1 , figure 2 , image 3 Shown is a smelting furnace for continuous smelting of crude tin from tin concentrate and continuous fuming of slag. The bottom is an integral furnace bottom 11, on which an outer wall 13 of the smelting furnace is built by masonry. The integrated metallurgical furnace includes a front-end top-blown smelting furnace connected to the bottom and a rear-end side-blown fuming depletion furnace.

[0024] The front-end top-blown smelting furnace includes a cylindrical furnace body 4, a material inlet 1 arranged on the top of the cylindrical furnace body, a melting spray gun 3 inserted into the furnace from the top of the cylindrical furnace body, and a smelting flue gas furnace arranged on the top of the cylindrical furnace body. Outlet 5, the thick tin discharge outlet 10 that is arranged at the bottom of the cylindrical furnace body.

[0025] The side-blowing fuming and depleting furnace includes a rectangular box-type furnace bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com