Preparation method of high-flux bulk material based on friction stir technology

A block material and friction stir technology, which is applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of limited material density and achieve the effects of large sample size, good sample contrast, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 provides a high-throughput preparation method of a magnesium-aluminum-zinc ternary alloy:

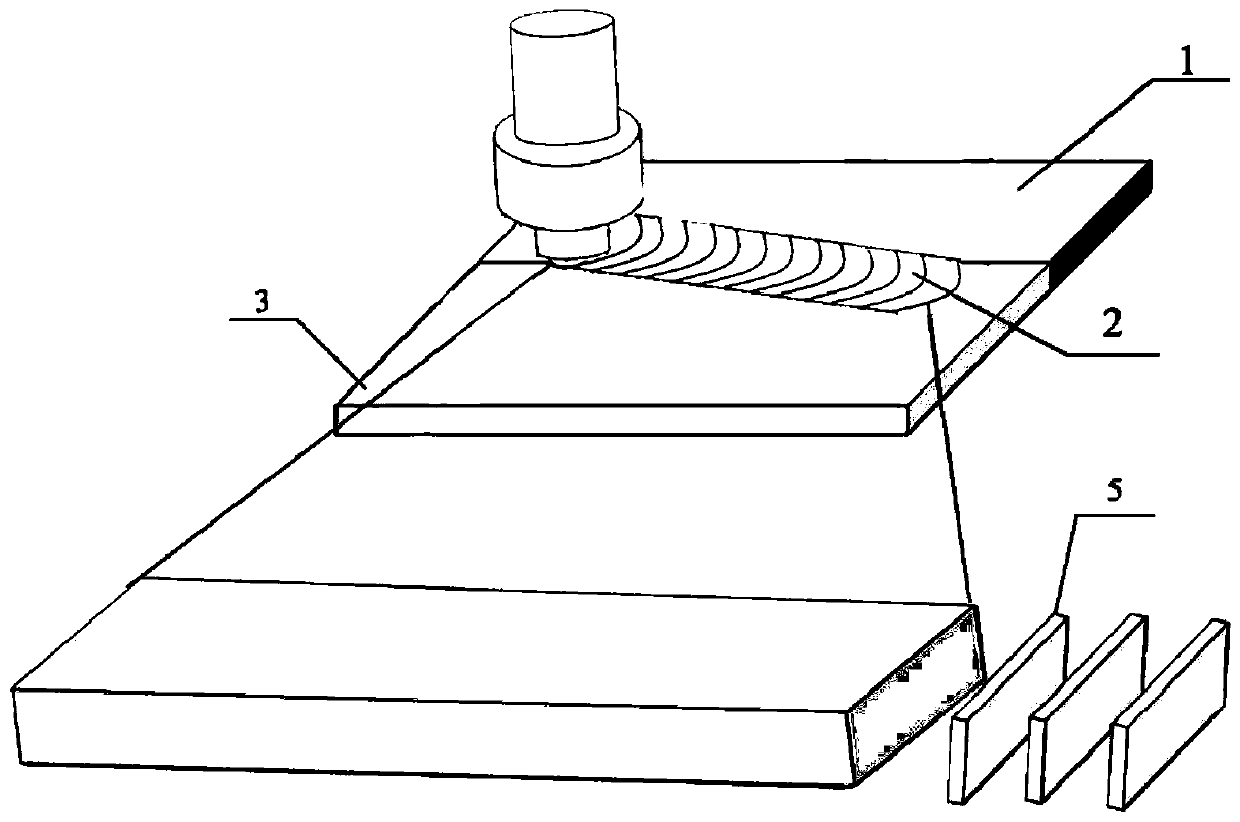

[0037] (1) Two ternary alloy plates whose components are Mg-3%Al-1%Zn dissimilar plate 1 and Mg-9%Al-1%Zn dissimilar plate 3 are used as the experimental base materials, dissimilar plate 1 and dissimilar The size of the plate 3 is 50mm*100mm*6mm, and the two ternary alloy plates are processed according to the preparation work described in the process steps: use acetone as the cleaning agent to clean the plates: clean for 3 minutes under the action of ultrasonic waves, remove Dust and oil stains on the surface of the parent material, the cleaned base material is dried for later use; use 240# to 2000# sandpaper to grind step by step, and the contact surface is polished to make it easier for the two materials to fit closer together, so as to ensure the prepared sample At the same time, the oxide film on the surface of the material is removed during this process, which f...

Embodiment 2

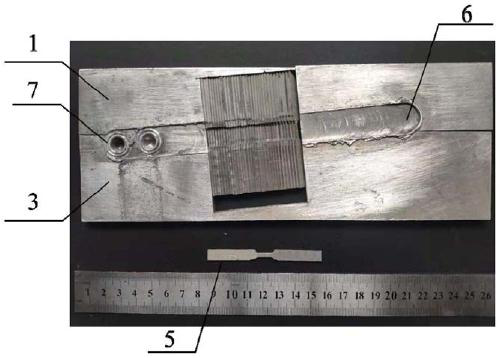

[0042] Example 2 provides a high-throughput preparation method of an Al-SiC composite material. Al-based composite materials with content of 0% and 40% respectively are used as the base material, and the plate size is: 50mm*100mm*6mm. The alloy plate is processed according to the preparation work described in the process steps. After cleaning and polishing, it is placed on the welding platform fixed.

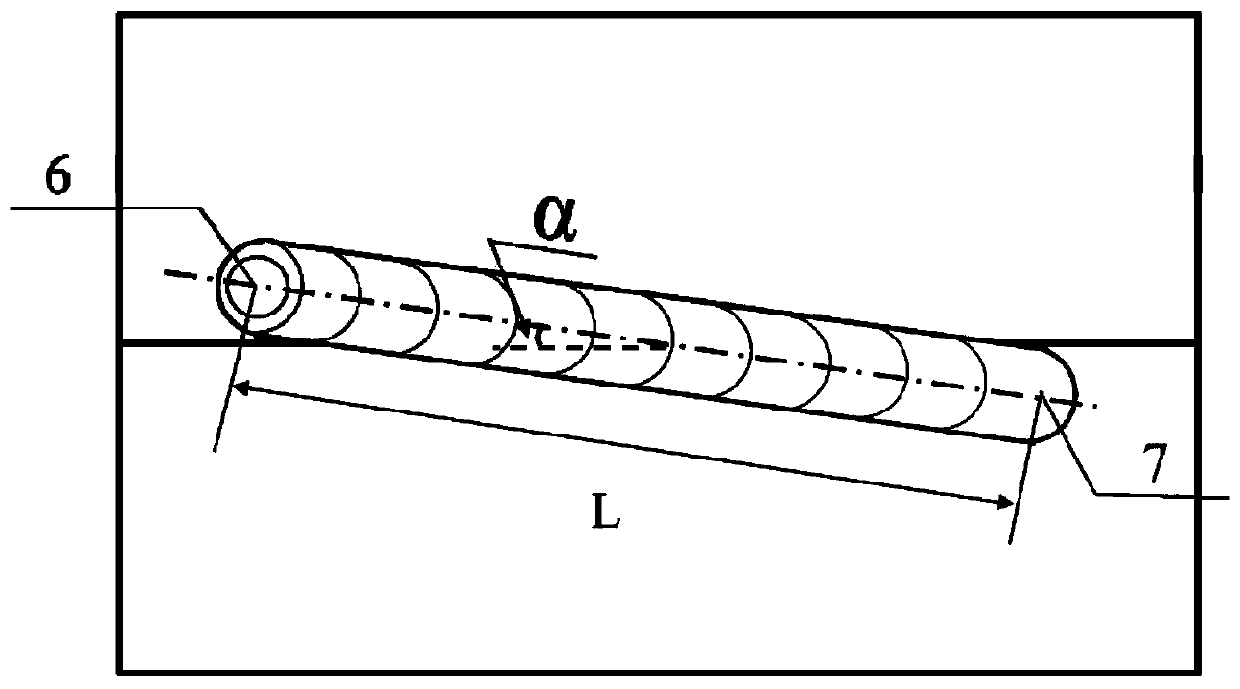

[0043] Use a threaded stirring needle with a needle length of 5.4mm and a diameter of 8mm for processing. The relative position of the stirring needle and the two plates is as follows Figure 5 As shown, at the starting position at 6, the stirring pin is completely on the Al alloy side and is tangent to the seam line; similarly at the end position 7, the stirring pin is completely on the Al-40%SiC side. The welding length L is 40mm. The rotating speed during welding is 600rpm, and the welding speed is 100mm / min. Processing direction such as Figure 5 As shown, changing the d...

Embodiment 3

[0046] Example 3 provides a high-throughput method for preparing an aluminum alloy containing copper, lithium, and magnesium. Al-Cu (special-shaped plate 3), Al-Mg (special-shaped plate 1) and wedge-shaped Al-Li (special-shaped plate 1) alloy plates were used as the experimental base material, and the alloy plates were processed according to the preparation work described in the process steps, cleaned After grinding, place it on the welding platform and fix it.

[0047] Use a threaded stirring needle with a needle length of 2.8mm and a diameter of 5mm for processing. The relative position of the stirring needle and the two plates is as follows Figure 6 As shown, at the beginning, the stirring pin is completely located on the special-shaped plate 3 (Al-Cu alloy) side, and is tangent to the seam line; at the end, the stirring head is completely located on the special-shaped plate 1 (Al-Mg) side. The welding length L is 40mm. The rotating speed during welding is 1200rpm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com