Material with biological adhesive and biodegradable component, and preparation method and application thereof

A polyurethane adhesive, amino technology, applied in the direction of surgical adhesives, applications, medical science, etc., to achieve strong offensive ability, improve shear strength and adhesive strength, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Provide a kind of preparation method of polyurethane adhesive, it is characterized in that, comprises the following steps:

[0035] S1. Drying of polyols: Take castor oil and polyethylene glycol, remove water under vacuum at 105-115°C for 2.5-3h, after the water removal is completed, let stand and cool down to 50-52°C;

[0036] S2. Synthesis of prepolymer: under the condition of nitrogen protection, after the dehydrated and dried polyol is heated to 70-72°C, add isophorone diisocyanate, and react for 6-7h under the condition of slow stirring;

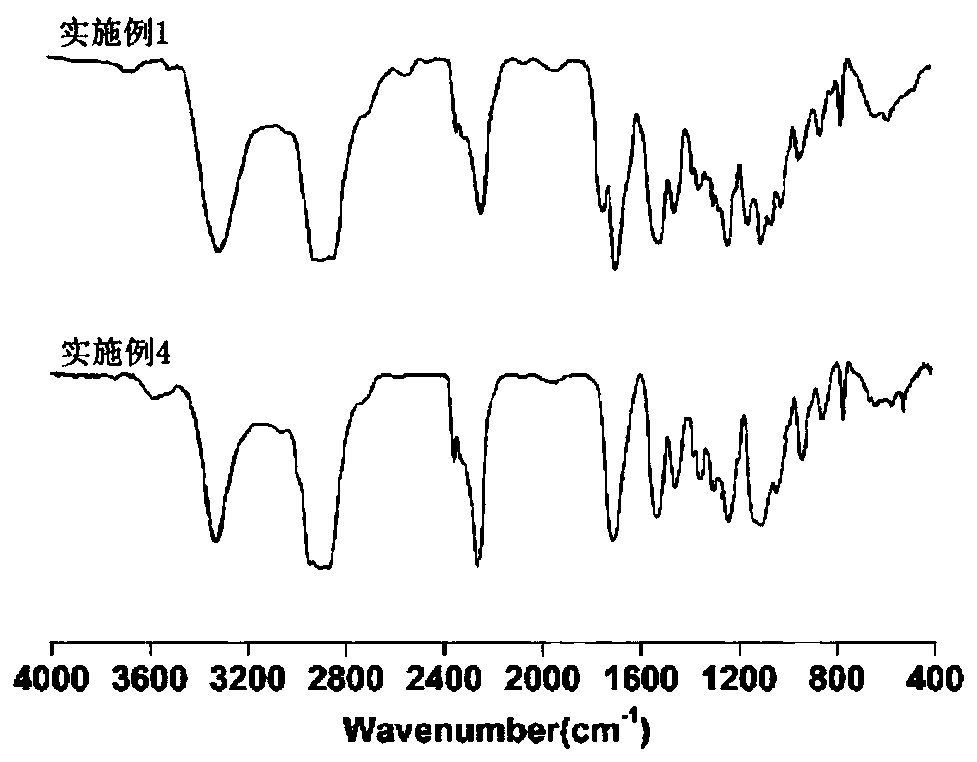

[0037] Grafting of S3, 2-amino-4-sulfonic acid benzoic acid: add the isopropanol solution containing 2-amino-4-sulfonic acid benzoic acid and methyl propionate to the prepolymer obtained in step S2, 70 React at a constant temperature of -72°C for 1-2 hours, after the reaction is completed, cool down to room temperature, and store the product in isolation from water vapor for later use;

[0038]The castor oil: polyethylene glycol...

Embodiment 1

[0048] Provide a kind of preparation method of polyurethane adhesive, comprise the following steps:

[0049] S1. Drying of polyols: first add 0.6g castor oil and 7.3g polyethylene glycol to the container, remove water in vacuum at 110°C for 2.5h, after the water removal is completed, let stand and cool down to 50°C;

[0050] S2. Synthesis of prepolymer: under the condition of nitrogen protection, after the dehydrated and dried polyol is heated to 70°C, add 4.2g of isophorone diisocyanate, and react for 6 hours under the condition of slow stirring;

[0051] Grafting of S3, 2-amino-4-sulfonic acid benzoic acid: add isopropanol containing 4g 2-amino-4-sulfonic acid benzoic acid and 5.8mg methyl propionate to the prepolymer obtained in S2 step The solution was 30mL, and reacted at a constant temperature of 70°C for 1h. After the reaction was completed, the product was cooled to room temperature, and the product was isolated from water vapor and stored for later use.

Embodiment 2

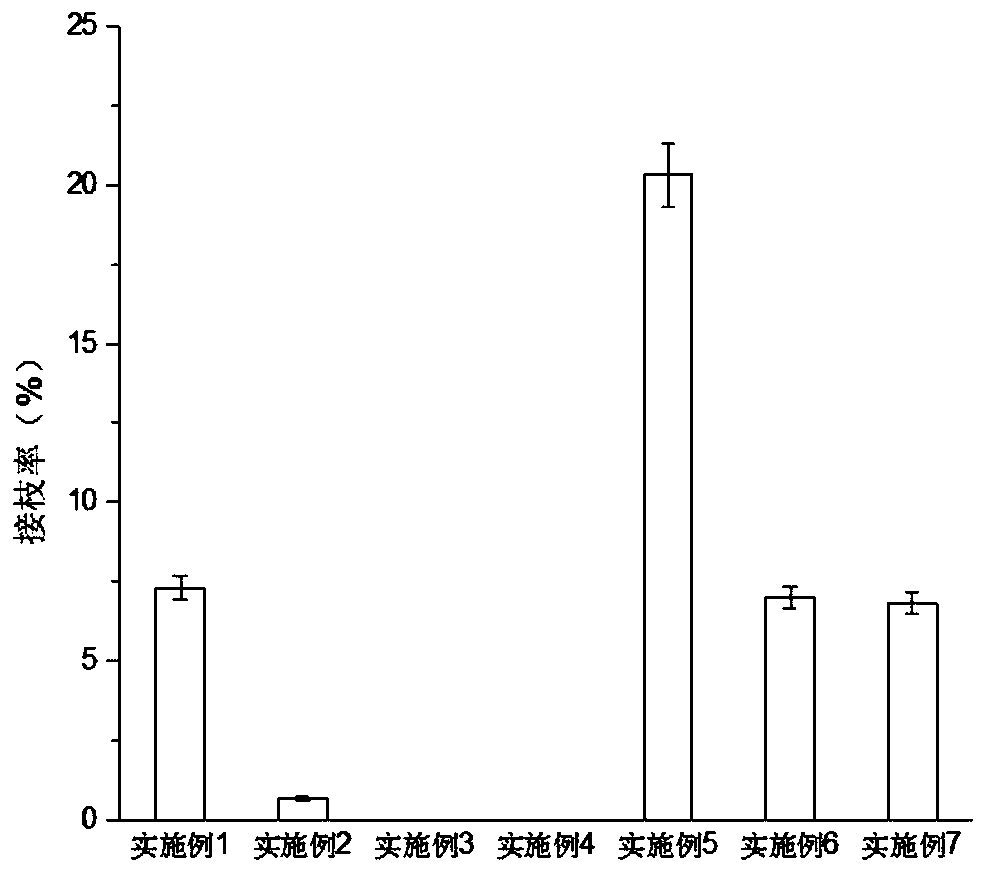

[0053] Methyl propionate was not added, and the remainder was completely consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com