Regenerative aluminum melting furnace

An aluminum melting furnace and regenerative technology, applied in furnaces, crucible furnaces, waste heat treatment, etc., can solve problems such as poor temperature self-control, overheating of molten aluminum, poor heat exchange structure, etc., to improve the utilization level and reduce contact. Area, the effect of reducing the degree of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

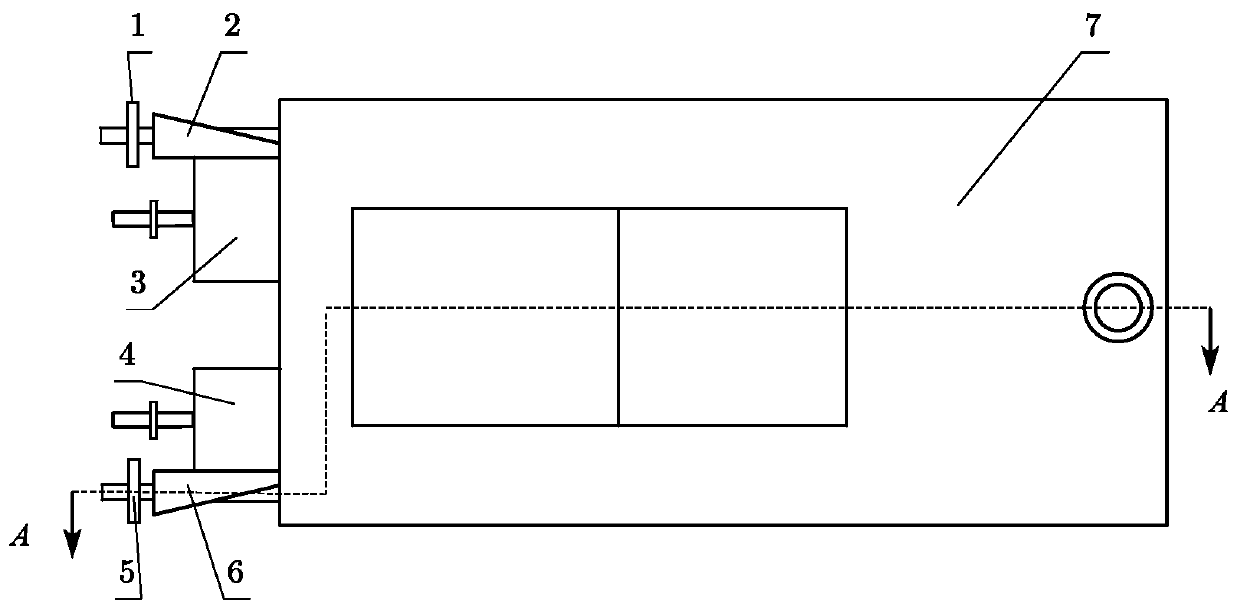

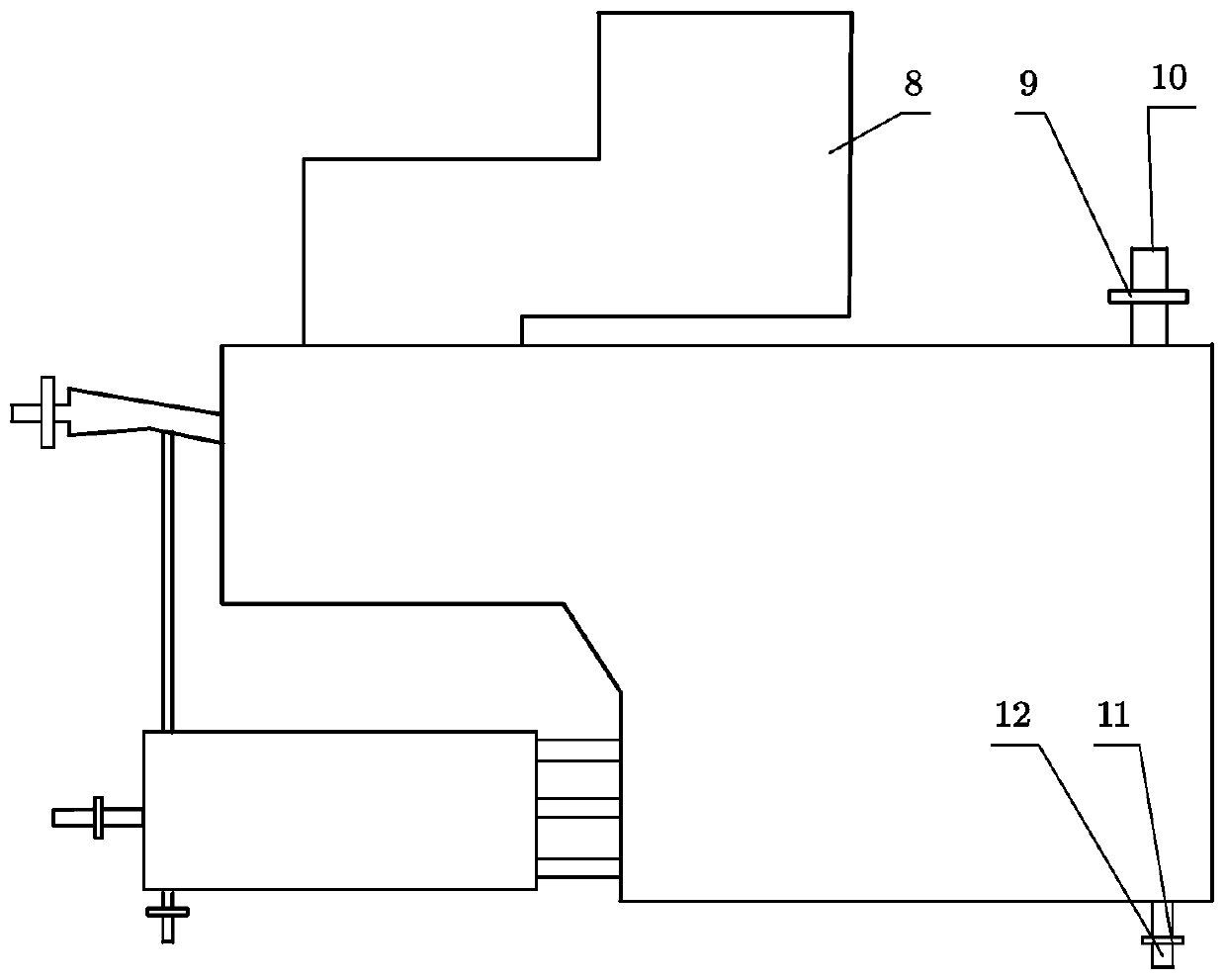

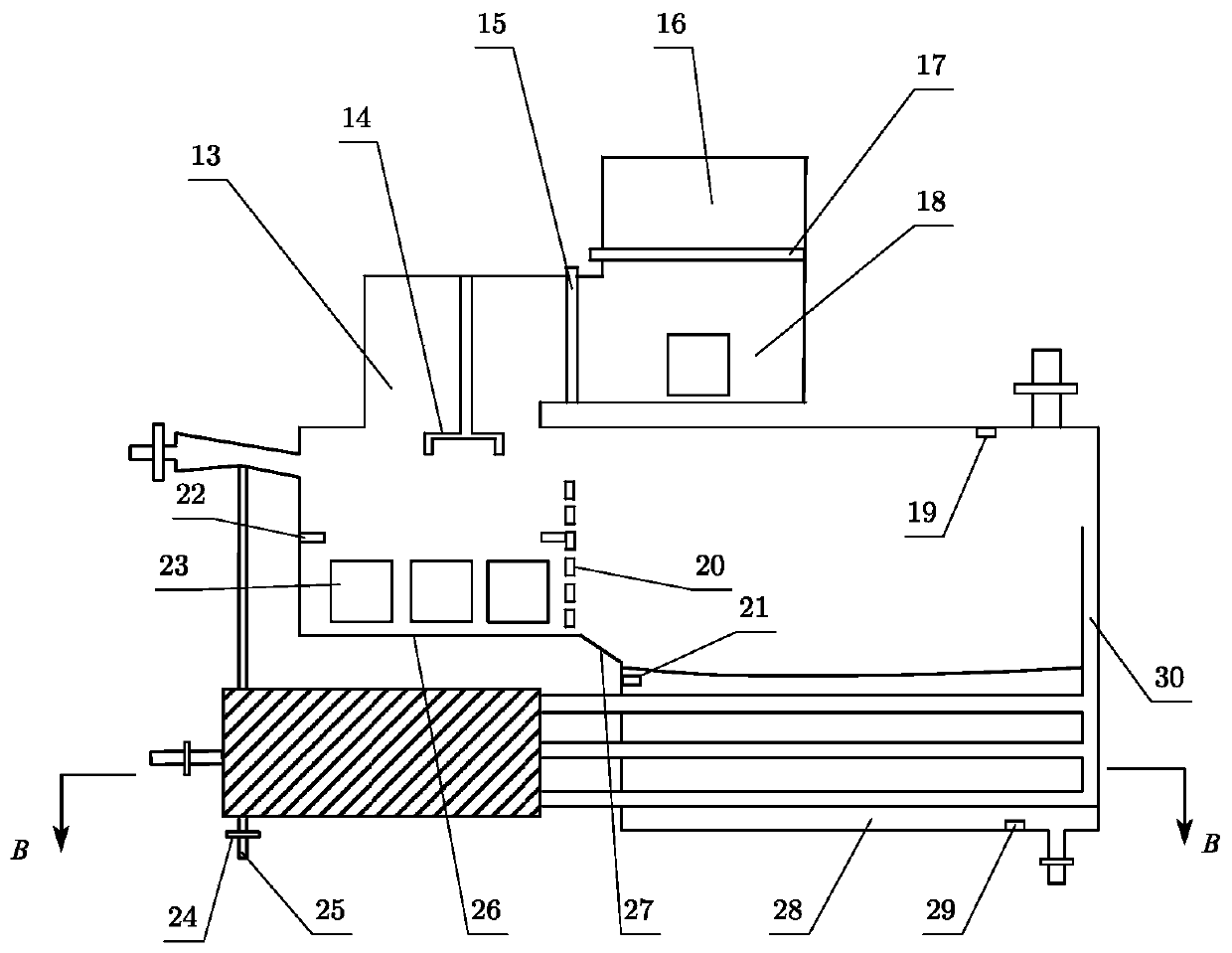

[0039] The regenerative aluminum melting furnace of this embodiment, refer to figure 1 , including a furnace body 7, the furnace body is provided with a feed inlet, the furnace body is provided with a burner 2, an aluminum ingot melting platform 26 and a molten pool 28, and the bottom of the molten pool is provided with a discharge port 12, and the aluminum ingot 23 passes through The feed inlet is placed on the aluminum ingot melting platform, and the burner generates hot flue gas to heat and melt the aluminum ingot. The liquid aluminum flows into the molten pool and is discharged through the discharge port; There are also heat exchange pipes (30, 35) inside. The function of the heat exchange pipes is to introduce the waste heat / hot flue gas into the molten pool to exchange heat with the aluminum liquid, and then output it to the outside of the furnace, and further recover it to the heat storage body. The inlet of the heat pipe is set above the molten pool, and extends into t...

Embodiment 2

[0065] In order to increase the utilization rate of waste heat, heat pipes can be directly arranged on the horizontal heat exchange pipes for sufficient heat exchange between hot flue gas and molten aluminum; the horizontal cross-sectional area of the horizontal heat exchange pipes can also be appropriately increased to form heat pipe flue gas flow channels; A heat pipe can be arranged on the heat pipe flue flow channel.

[0066] For details, see Figure 5 , the horizontal heat exchange tube 35 is changed to the heat pipe flue gas flow channel 39, and the heat pipe flue gas flow channel 39 is distributed horizontally, and its structure is not limited to the horizontal thin channel (the channel height is determined by the actual project, such as 0.1m), equidistant or unequal Indirect circular ducts, equally spaced or unequal indirect square ducts. The heat pipe one 38 is vertically inserted into the heat pipe flue flow channel 39. The hot side of the heat pipe is in contact ...

Embodiment 3

[0068] In order to reduce the corrosion of the aluminum liquid by the flue gas and reduce the burning loss of the aluminum liquid. A heat exchange plate 40 is arranged in the furnace body and close to the upper part of the molten pool. Furthermore, a solid heat exchange tube with high thermal conductivity can be arranged on the heat exchange plate.

[0069] Specific examples such as Figure 6 As shown, the heat exchange plate 40 is arranged horizontally and sealed to the wall of the molten pool. The side of the heat exchange plate 40 close to the aluminum ingot melting platform 26 has a square hole (not limited to a square), and the baffle is arranged downward along the hole. The baffle is inserted into the molten aluminum but does not prevent the horizontal flow of the molten aluminum in the molten pool. In addition, during operation, the molten aluminum is not higher than the plate platform 40 .

[0070] In a further solution, a solid heat exchange tube 41 with high thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com