Blade air film hole machining quality tracing system and method

A technology of processing quality and traceability system, applied in the field of traceability system, can solve the problem of low automation of information acquisition, achieve the effects of shortening delivery time, saving production cost, and reasonable system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

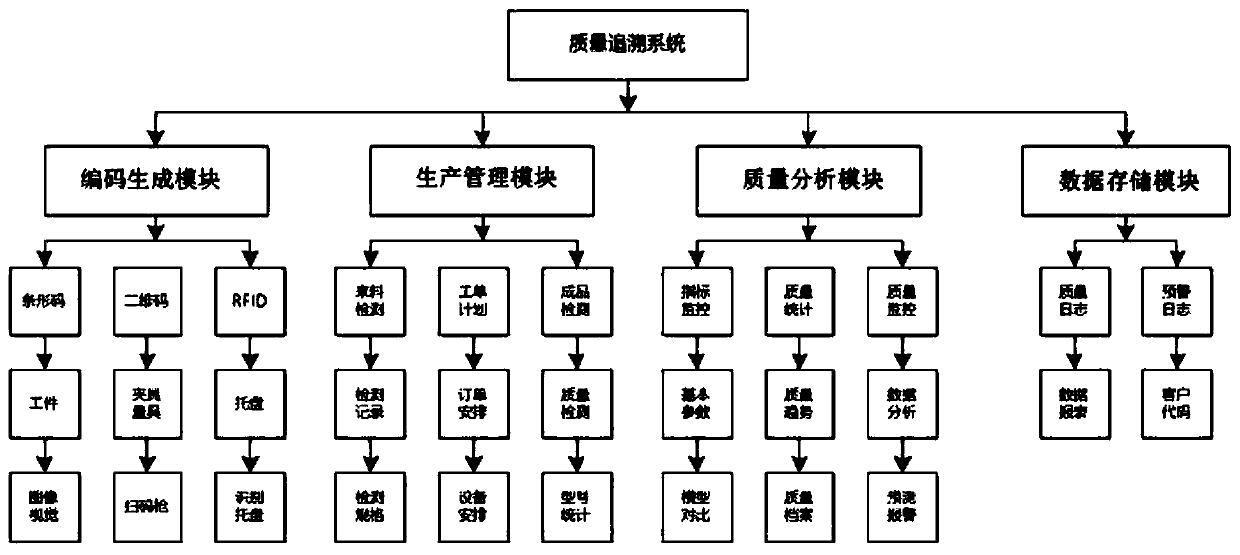

[0046] Example: see figure 1 , The present embodiment provides a blade air film hole processing quality traceability system. The hardware mainly includes code reading equipment, industrial control computers, mice, keyboards, printers, etc. The code reading equipment supports mainstream code scanning guns and RFID readers on the market. Data input generated by devices such as barcode readers and visual barcode readers. The system software part has MES system interface, which can be integrated into the MES system as a plug-in to realize the automatic traceability function, or the same traceability function can be realized by manually importing the corresponding data, which can be adapted to different working conditions or adjusted according to customer needs Regardless of whether the data is imported automatically or manually, the software part of the blade air film hole processing quality traceability system of the present invention has the following figure 1 The shown sub-module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com