Method for producing coumestrol by using cultured roots of leguminous plant

A technology of coumestrol and production method, which is applied in the directions of biochemical equipment and methods, tissue culture, cell culture medium, etc., can solve the problems of short-term, small amount of coumestrol, difficulty in commercialization and the like, and achieve cost saving , the effect of saving time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] [Example 1] Germination of bean seeds and induction of isolated plants

[0062] After sterilizing each surface of bean seeds (Glycine max, preferably mythical bean variety) and Bean bean with a 2% by weight aqueous solution of sodium hypochlorite (Sodium Hypochlorite) for 20 minutes, they were washed 3 times with sterile water. Then, according to the bean species, 0.5-1.0MS medium (Murashige and Skoog Medium, Haarlem, Netherlands) supplemented with 30g / L sucrose was used to induce the germination of plants in the reactor under the light condition of 25±1°C for 2 weeks. .

Embodiment 2

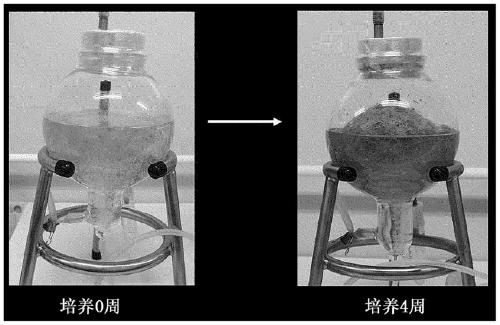

[0063] [Example 2] Induction and Proliferation of Bean Cultured Roots

[0064] After the radicle induction culture root of the plant body germinated from the reactor, in the spherical (BulbType) bioreactor (generally can buy from the market, refer to that the air volume is 3L) figure 1 ) within 2L of 0.5MS medium ( Murashige and Skoog medium, Duchefa, Netherlands) proliferated root cultures for 4 weeks. In addition, the roots were multiplied and cultured for 4 weeks under the same conditions as above using 1.0 MS medium. The 0.5MS medium is a medium prepared by setting the concentration of raw materials such as inorganic substances used in the medium to 1 / 2 of that of a normal MS medium. same base medium. The medium was sterilized at 121°C and 1.2 atmosphere for 35 minutes after adjusting the pH to 5.8 with 1N NaOH. The cultured roots were cut into 1-1.5 cm and inoculated into the culture medium at an inoculation density of 4 g / L on the basis of fresh weight, and then cult...

Embodiment 3

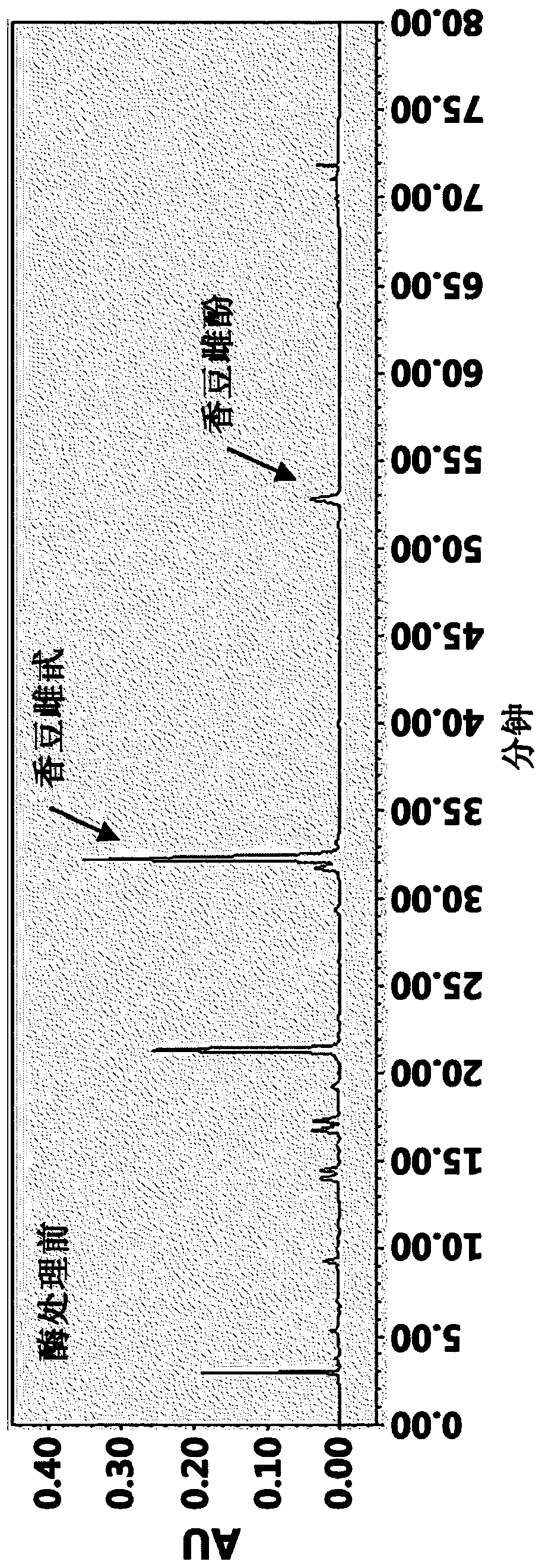

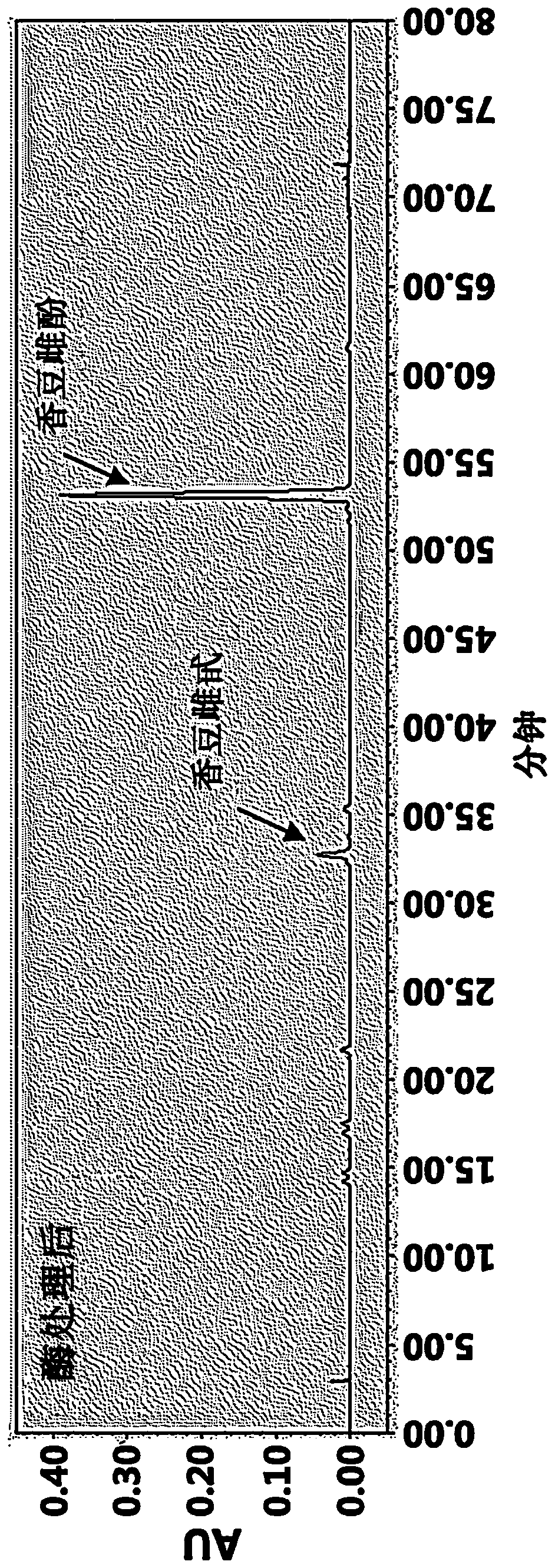

[0066] [Example 3] Preparation of extract and enzyme treatment

[0067] 1. Preparation of Extract

[0068] The cultured roots of beans harvested and dried according to the above Examples 1 and 2 were dipped into 80% (w / v) ethanol water so that the weight ratio of cultured roots: ethanol water was 1:30 to 1:50 (preferably 1:30 ), and extracted at room temperature for 24 hours. The extract was filtered through a filter paper, and the solvent was evaporated to dryness to obtain a powder (extract). In addition, through repeated extraction experiments, it can be confirmed that when using the cultured root produced in Example 1 to prepare the extract, the components in the extract remain uniform, and it is confirmed that a large amount of extraction can be carried out by combining the extract preparation methods such as subculture. Production.

[0069] 2. Enzyme treatment

[0070] After the extract powder was treated with the same weight of liquid-phase pectinase (pectinase) enz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com