Method for reducing coupling interference of electrostatic micro-mirror angle detection sensor

An angle detection and coupling interference technology, applied in the field of micro-nano optical devices, can solve the problems of high requirements for detection signal processing circuits, detection signal coupling interference, and reduction of detection accuracy, so as to improve the control accuracy of micromirrors, reduce the complexity, The effect of improving the signal-to-noise ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 micromirror design

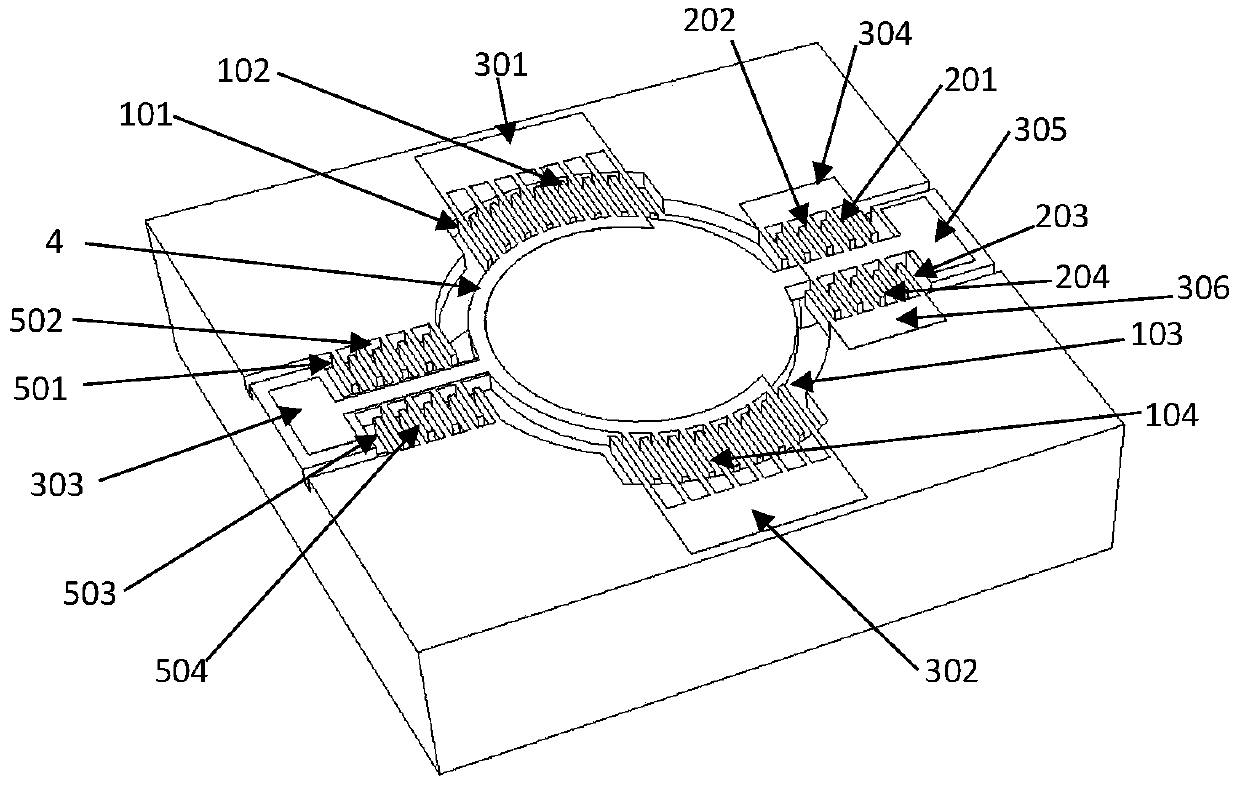

[0040] Such as Figure 4 Shown is a micromirror design, the mirror surface is circular, and the side of the mirror surface is provided with a first rotating comb 102 and a second rotating comb 104, which are respectively connected with the first fixed comb 101 and the third fixed comb fixed on the outer frame. The comb teeth 103 are staggered to form two groups of driving comb teeth. A rotating shaft is arranged in a direction perpendicular to the line connecting the rotating comb teeth, one end of the rotating shaft is connected to the circular mirror, and the other end is connected to the peripheral frame. A first movable detection comb 202 and a second movable detection comb 204 , a first movable balance comb 501 and a second movable balance comb 503 are arranged on the side of the rotating shaft. The first movable detection comb 202 and the second movable detection comb 204 respectively interleave with the first fixed detection co...

Embodiment 2

[0041] Embodiment 2 micromirror design

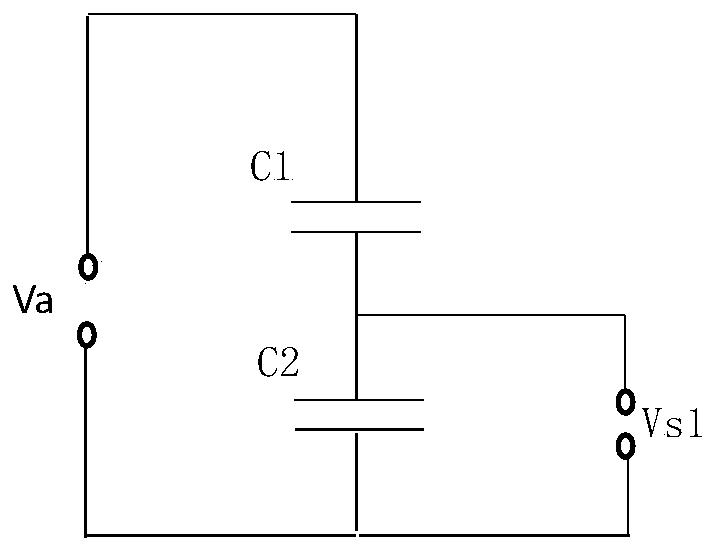

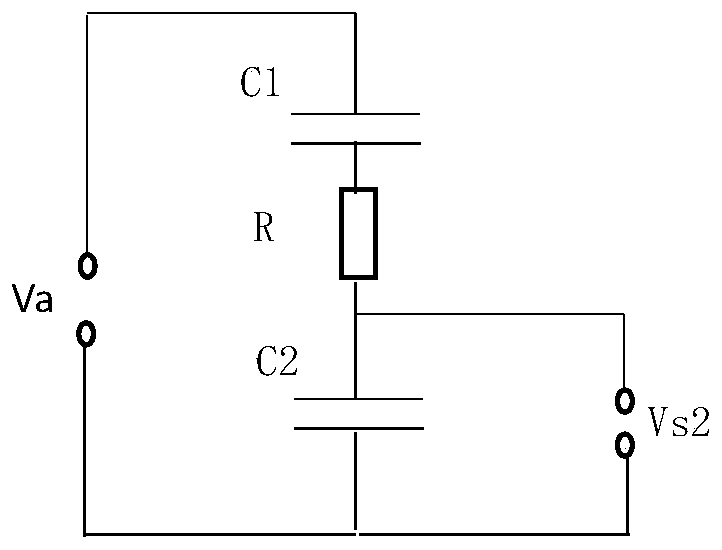

[0042] Such as Figure 5 Shown is a micromirror design, the difference from Example 1 is that the mirror surface is rectangular, all driving combs, detection combs and corresponding lead areas are doped, and then all driving combs, detection combs The teeth, pad areas and corresponding lead areas are deposited with an aluminum metal layer with a thickness of 500nm. According to the principle of resistance-capacitance voltage division, the coupling interference caused by the driving signal to the detection signal is Vs2=Va XC2 / (XC1+XC2+R), where XC1 and XC2 are the capacitive reactances of C1 and C2 respectively, and C1=C2=C, then XC1=XC2=1 / 2πfC, where f is the drive signal frequency, which is 2kHz in the present embodiment; C=NεS / d, where N is the logarithm of the comb teeth, which is 100 in the present embodiment; ε is the air permittivity, The value is 8.85×10 -12 F / m; S is comb tooth side area, is 2 * 10 in the present embodiment ...

Embodiment 3

[0043] Embodiment 3 Micromirror manufacturing method

[0044] In order to better illustrate the manufacturing method of the micromirror of the present invention, a specific operation process after the existing manufacturing method is added to the method of the present invention is listed. Such as Image 6

[0045] A method for making a micromirror that reduces the coupling interference of an electrostatic micromirror angle detection sensor:

[0046] (1) Prepare SOI (Silicon On Insulator) silicon wafer. The SOI silicon wafer includes a three-layer structure of base silicon 701 , buried oxide layer 702 and top layer silicon 703 from bottom to top. The base silicon 701 and the top layer silicon 703 are high-resistance silicon, and the resistivity range is 1-10 8 Ω·cm. The thickness of the base silicon 701 is 100-800 μm, the thickness of the buried oxide layer is 0.5-10 μm, and the thickness of the top layer is 5 μm-100 μm. Preferably, the base silicon 701 has a thickness of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com