Si-based modified Ge monolithic same-layer photoelectric device

A photoelectric device and modification technology, which is applied in the field of photoelectric communication, can solve the problems of low device integration, long process cycle, and high production cost, and achieve the effects of high device integration, low process cost, and reduced effective mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

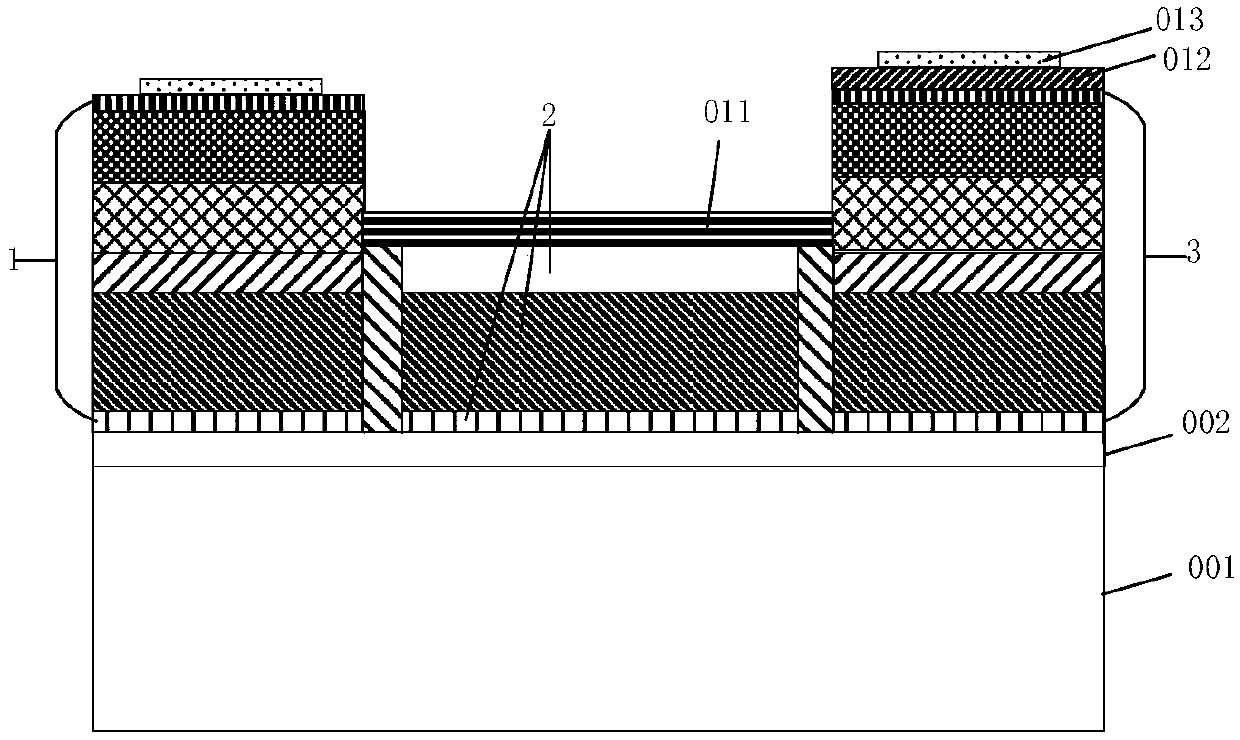

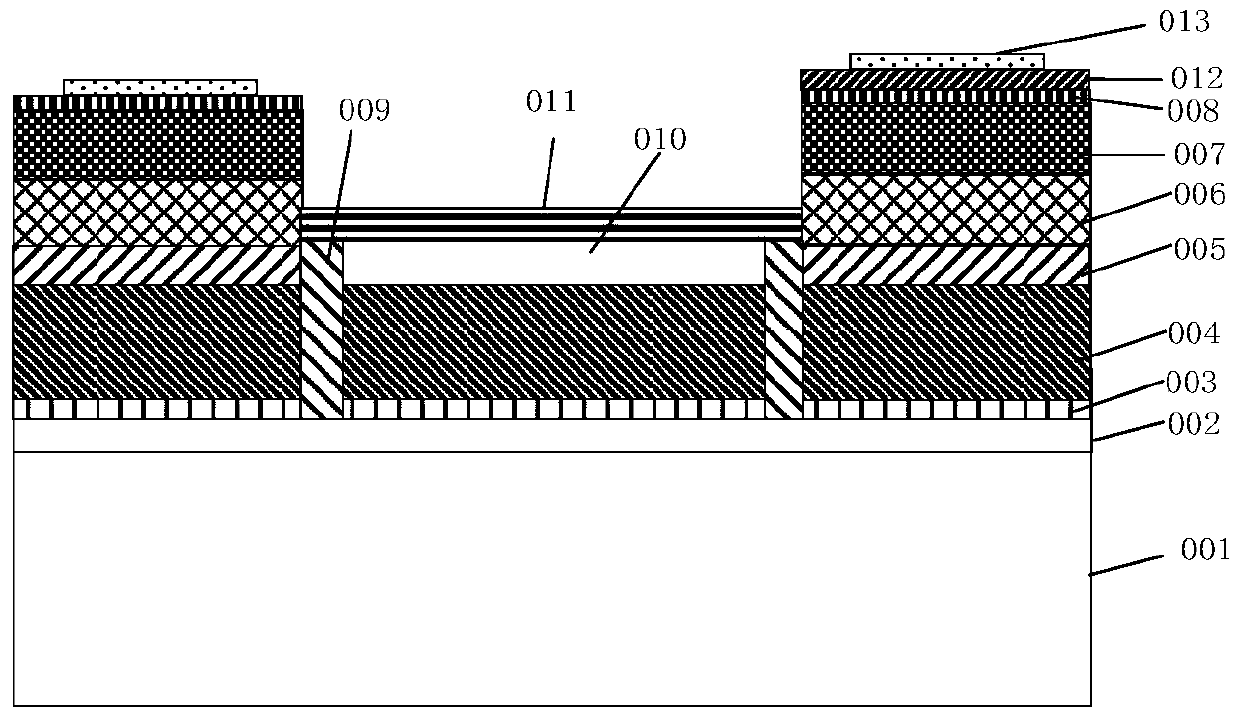

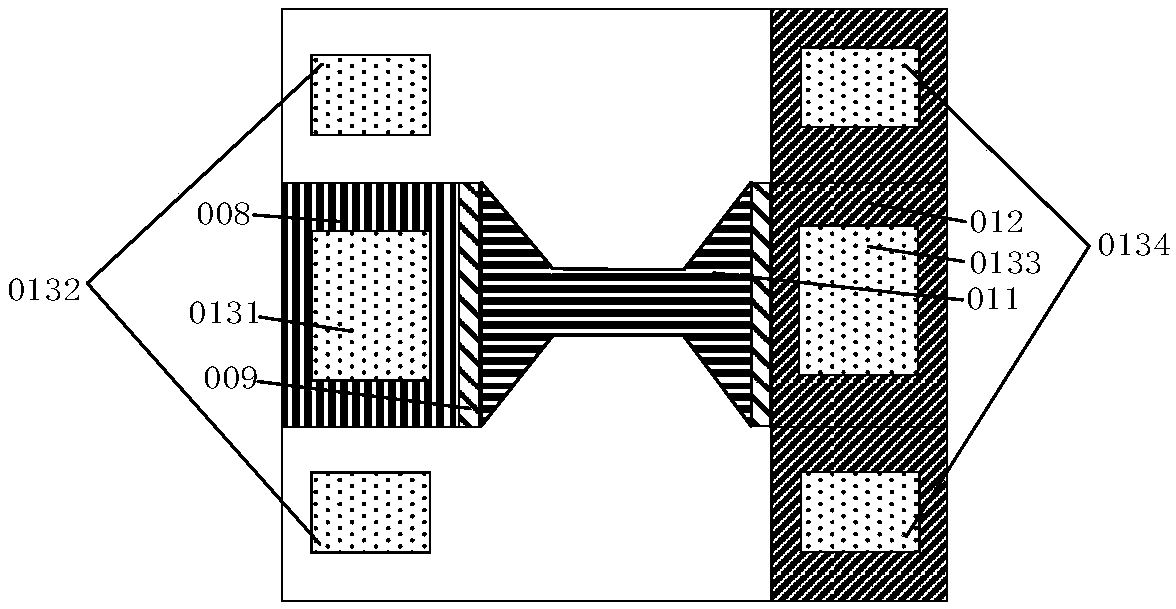

[0047] refer to figure 1 , figure 1 Schematic structure of Si-based modified Ge monolithic same-layer optoelectronic device provided for the present invention Figure 1 , specifically including a substrate 001; a buried layer 002 is disposed on the substrate 001; a light emitter part 1, a waveguide part 2 and a detector part 3 are sequentially arranged on the buried layer 002 from left to right; the light emitter part 1 and the detector part 3 are respectively provided with electrodes 013 .

[0048] Wherein, the substrate 001 is a P-type doped Si substrate 001 with a height of 30-750 nm and a doping concentration of 10 18 cm -3 , the buried layer 002 is a P-type doped Ge layer with a height of 50 nm and a doping concentration of 10 20 cm -3 .

[0049] It should be noted that the light emitter part 1, the waveguide part 2 and the detector part 3 are only arranged in the middle area of the buried layer 002, further, the top of the light emitter part 1 and the detector part...

Embodiment 2

[0079] A method for preparing a Si-based modified Ge monolithic photoelectric device with the same layer provided by the embodiment of the present invention, such as Figure 6a ~ Figure 6n (1) as shown, Figure 6a ~ Figure 6n (1) A schematic diagram of the preparation process of a Si-based modified Ge monolithic same-layer photoelectric integrated device provided by the embodiment of the present invention, the specific steps include:

[0080] S101. Substrate 001 is selected. like Figure 6a As shown, the P-type Si substrate with a height of 30-750nm is selected as the initial material, and the doping concentration is 10 18 cm -3 .

[0081] S102, growing the buried layer 002. like Figure 6b As shown, at a temperature of 330° C., a P-type doped Ge layer with a height of 50 nm is epitaxially grown on the substrate layer 001 by chemical vapor deposition, and the doping concentration is 10 20 cm -3 .

[0082] S103 , growing the first intrinsic Ge layer 003 . like Figur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com