Ceramic simulating coating as well as preparation method and system thereof

A technology for preparation system and imitation porcelain coating, which is applied in mixing methods, chemical instruments and methods, mixers, etc., and can solve problems affecting the quality of coatings and uneven stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

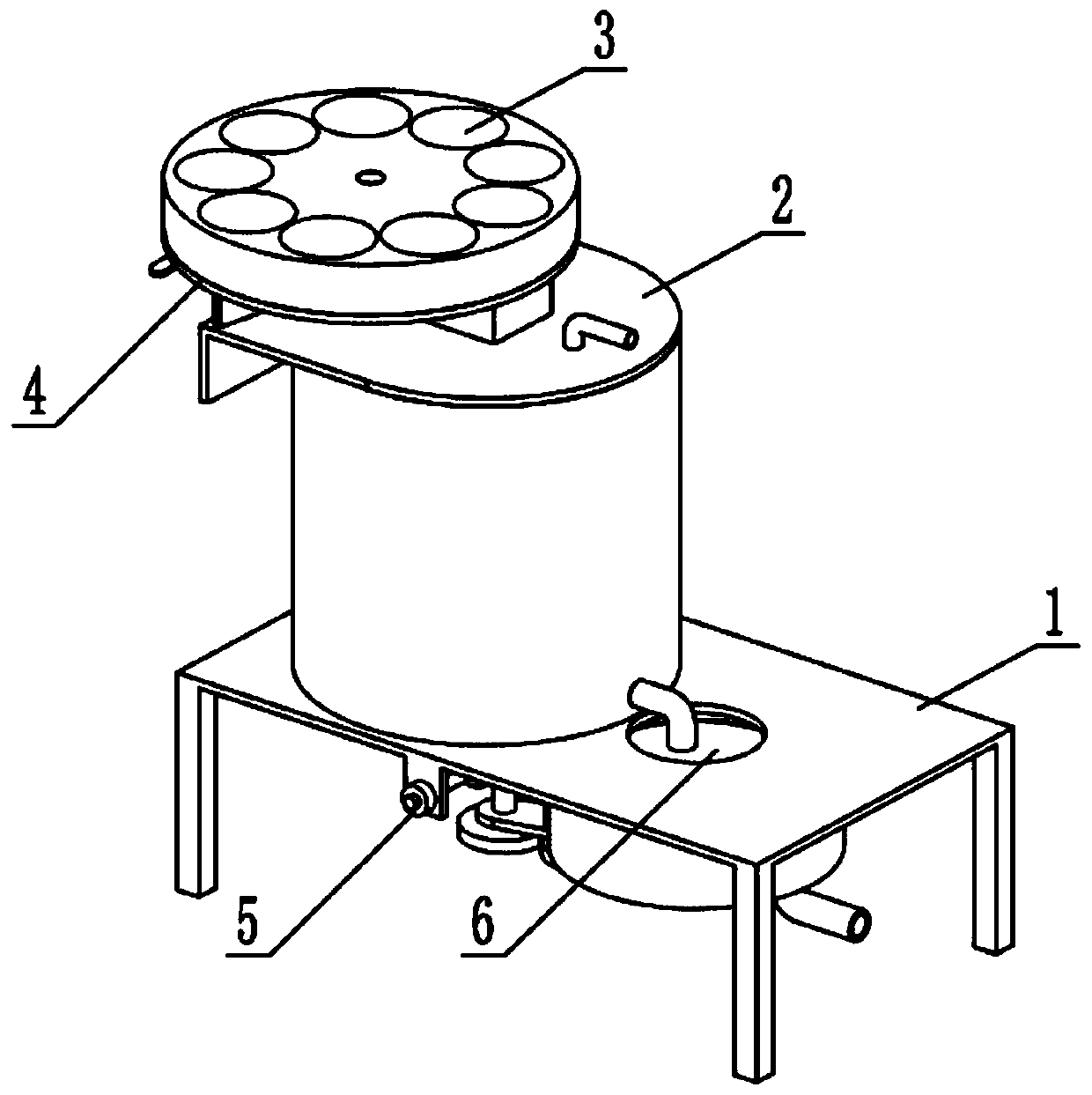

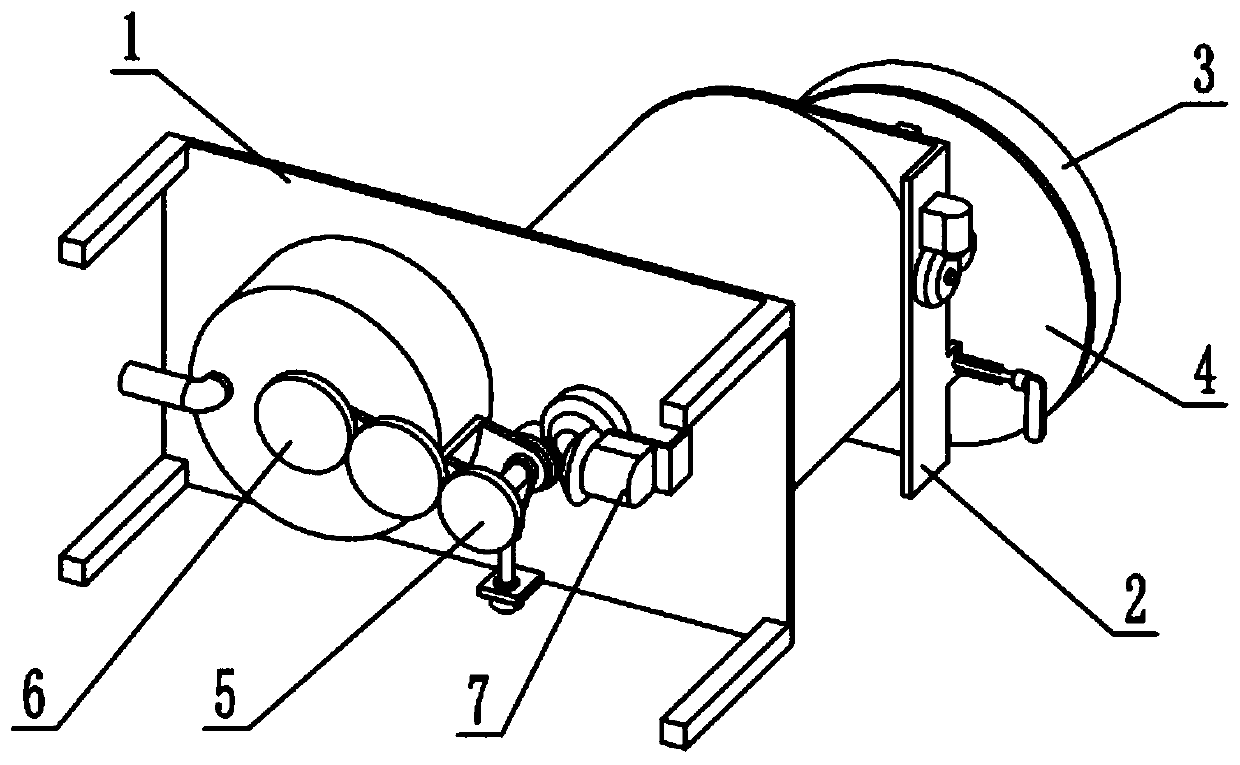

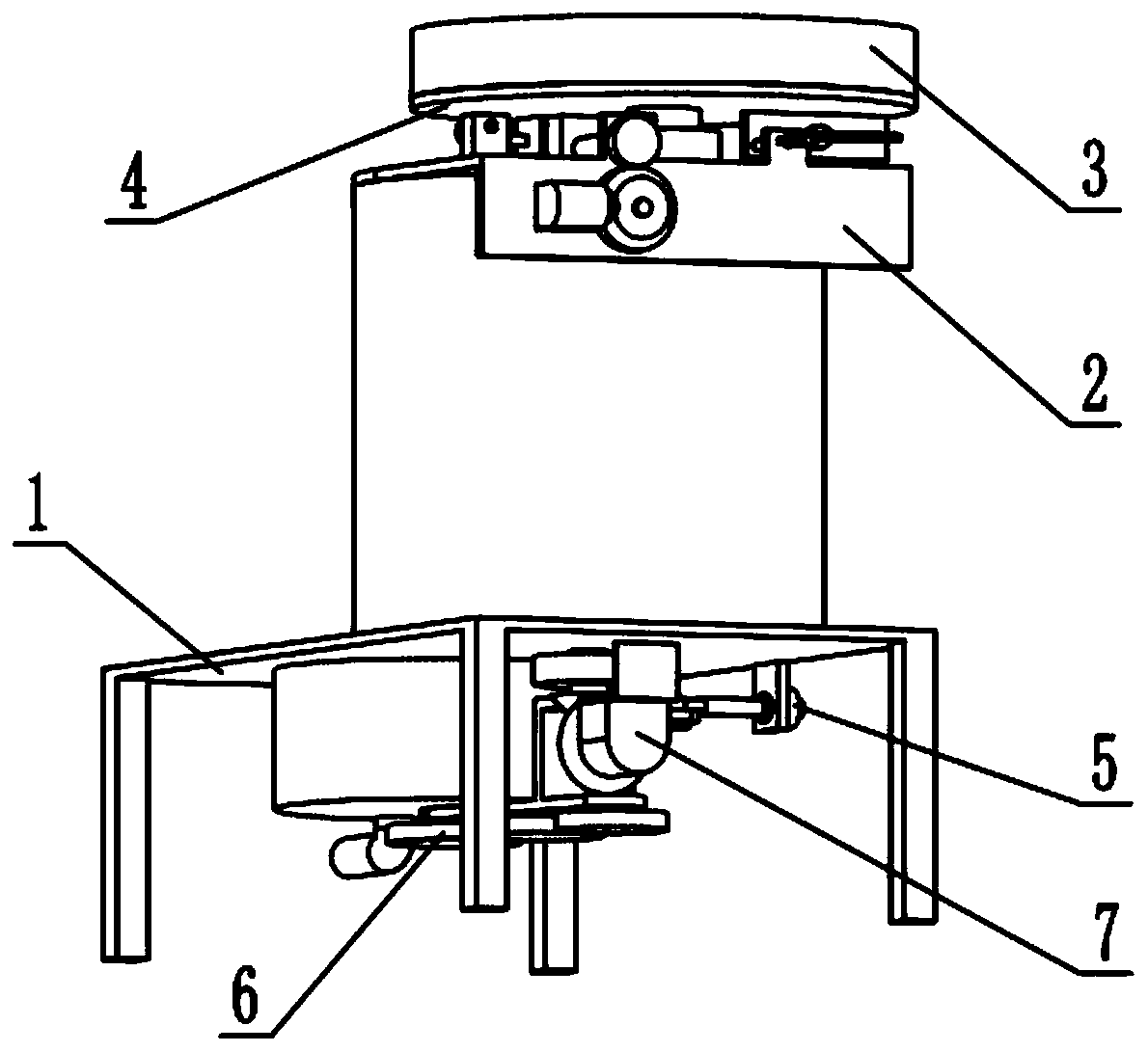

[0036] like Figure 1-13 As shown, a preparation system for imitation porcelain paint includes a stirring main frame 1, an upper cover mechanism 2, a feeding mechanism 3, a feeding blocking mechanism 4, a transmission mechanism 5, a filtering mechanism 6 and a stirring mechanism 7, and the upper cover mechanism 2 is fixedly connected to the upper end of the stirring main frame 1, the feeding mechanism 3 is rotatably connected to the upper cover mechanism 2, the described feeding blocking mechanism 4 is rotatably connected to the feeding mechanism 3, and the feeding blocking mechanism 4 and the upper cover The mechanism 2 is slidingly connected, the filter mechanism 6 is rotatably connected to the stirring main frame 1, the transmission mechanism 5 is rotatably connected to the filter mechanism 6 and is connected in transmission, the transmission mechanism 5 is rotatably connected to the stirring main frame 1, and the The stirring mechanism 7 is rotatably connected to the stirr...

specific Embodiment approach 2

[0039] like Figure 1-13 As shown, the stirring main frame 1 includes a supporting main board 1-1, a stirring round pipe 1-2, a discharge pipe I1-3, a supporting leg 1-4, a mounting plate I1-5, a filter barrel 1-6, an outlet Material pipe II 1-7 and motor mounting plate 1-8, the four corners of supporting main board 1-1 are all provided with supporting legs 1-4, and stirring circular pipe 1-2 is fixedly connected on the upper end surface of supporting main board 1-1, and stirring circle The pipe 1-2 is provided with a heating ring, the filter bucket 1-6 is fixedly connected to the lower end surface of the supporting main board 1-1, and the mounting plate 1-5 and the motor mounting plate 1-8 are fixedly connected to the lower surface of the supporting main board 1-1. On the end face, the lower end of the mixing tube 1-2 is provided with a discharge pipe Ⅰ1-3, the lower end of the filter barrel 1-6 is provided with a discharge pipe Ⅱ1-7, and the discharge pipe Ⅰ1-3 and the disch...

specific Embodiment approach 3

[0041] like Figure 1-13 As shown, the upper cover mechanism 2 includes an upper cover plate 2-1, a fixed shaft 2-2, a feed pipe 2-3, a water inlet pipe 2-4, a fixed sliding seat 2-5, a mounting plate II 2-6, The fixed pin 2-7, the locking plate 2-8 and the gear ring 2-9, the upper cover plate 2-1 are fixedly connected to the upper end of the mixing tube 1-2, and the upper cover plate 2-1 is provided with a feed pipe 2- 3 and water inlet pipe 2-4, fixed shaft 2-2, fixed sliding seat 2-5, mounting plate II 2-6 and locking plate 2-8 are all fixedly connected on the upper end surface of upper cover plate 2-1, and fixed pin 2- 7 is fixedly connected to the rear end of the upper cover plate 2-1, and the gear ring 2-9 is fixedly connected to the lower end surface of the upper cover plate 2-1;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap