Covalent organic framework material as well as synthesis method and application thereof

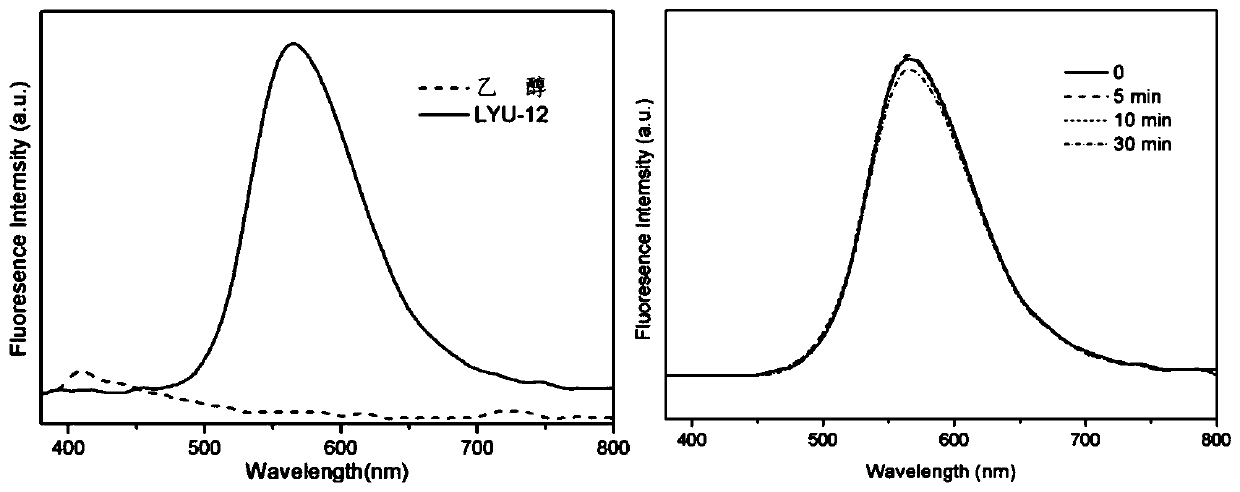

A technology of covalent organic framework and synthesis method, which is applied in the fields of analysis materials, luminescent materials, material excitation analysis, etc., to achieve the effect of sensitive fluorescence response behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Example 1: Synthesis of covalent organic framework material LYU-12

[0023]

[0024] Add 7.0mg of 2,4,6-trihydroxy-1,3,5-trithenaldehyde and 16.9mg of 2,5-dibutoxy-1,4-phthalhydrazide to a 10mL ampoule . Then add 1mL of 1,4-dioxane, 1mL of mesitylene and 1mL of ethanol, shake well and add 0.3mL of 9M acetic acid solution. Place the ampoule in liquid nitrogen, pump the air to 0mbar after the solution solidifies, and then seal the ampoule. It was placed in an oven and reacted at 80° C. for five days. After the reaction, a solid was produced at the bottom of the ampoule, and the solid was transferred to a centrifuge tube, washed with acetone and tetrahydrofuran for 3 times, respectively. The solid was dried at 100° C. to obtain 18.1 mg of brown yellow solid powder LYU-12 with a yield of 82%.

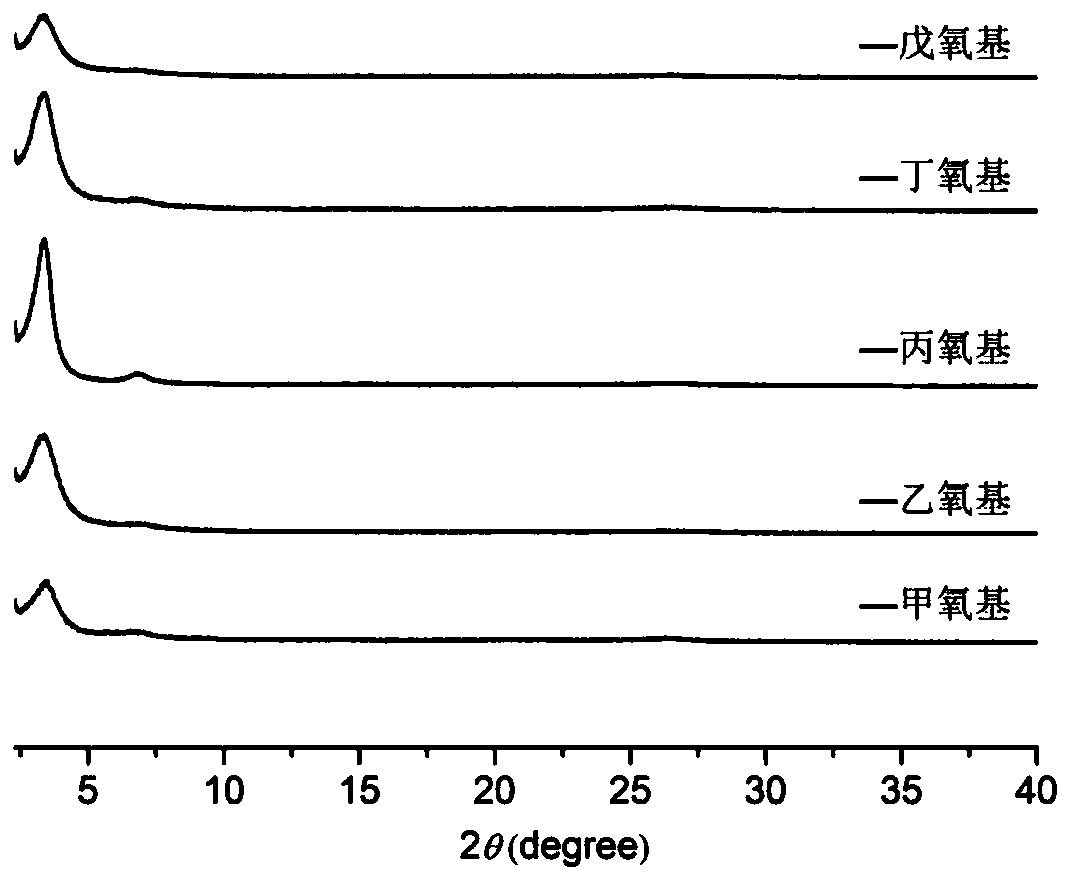

[0025] figure 1 (-Butoxy) is the X-ray diffraction pattern of LYU-12 in Example 1. It can be seen from the comparison of spectra that the powder X-ray diffraction of this ty...

Embodiment 2

[0029] Example 2: Synthesis of covalent organic framework material LYU-12

[0030] Add 7.0mg of 2,4,6-trihydroxy-1,3,5-trithenaldehyde and 11.3mg of 2,5-dibutoxy-1,4-phthalic hydrazide to a 10mL ampoule middle. Then add 1mL of mesitylene and 2mL of ethanol, shake well and add 0.3mL of 9M acetic acid solution. Place the ampoule in liquid nitrogen, pump the air to 0mbar after the solution solidifies, and then seal the ampoule. It was placed in an oven and reacted at 150° C. for seven days. After the reaction, a solid was produced at the bottom of the ampoule, and the solid was transferred to a centrifuge tube, washed with acetone and tetrahydrofuran for 3 times, respectively. The solid was dried at 100°C to obtain 12.1 mg of LYU-1212 as a brown yellow solid powder with a yield of 71%.

Embodiment 3

[0031] Example 3: Synthesis of covalent organic framework material LYU-12

[0032] Add 7.0mg of 2,4,6-trihydroxy-1,3,5-trithenaldehyde and 22.5mg of 2,5-dibutoxy-1,4-phthalhydrazide to a 10mL ampoule . Then add 1mL n-butanol, 1mL o-dichlorobenzene and 1mL ethanol, shake well and add 0.3mL 9M acetic acid solution. Place the ampoule in liquid nitrogen, pump the air to 0mbar after the solution solidifies, and then seal the ampoule. Put it in an oven and react at 90°C for one day. After the reaction, a solid was produced at the bottom of the ampoule, and the solid was transferred to a centrifuge tube, washed with acetone and tetrahydrofuran for 3 times, respectively. The solid was dried at 100° C. to obtain 19.2 mg of brown yellow solid powder LYU-12 with a yield of 69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com