Hollow slab bridge bending and shearing mixed reinforcing method

A hollow, bending and shearing technology, applied in bridge reinforcement, bridge, bridge maintenance, etc., can solve the problems of reducing the clearance under the bridge, single reinforcement effect, cumbersome operation, etc., and achieve high construction efficiency, comprehensive reinforcement effect and good integrity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

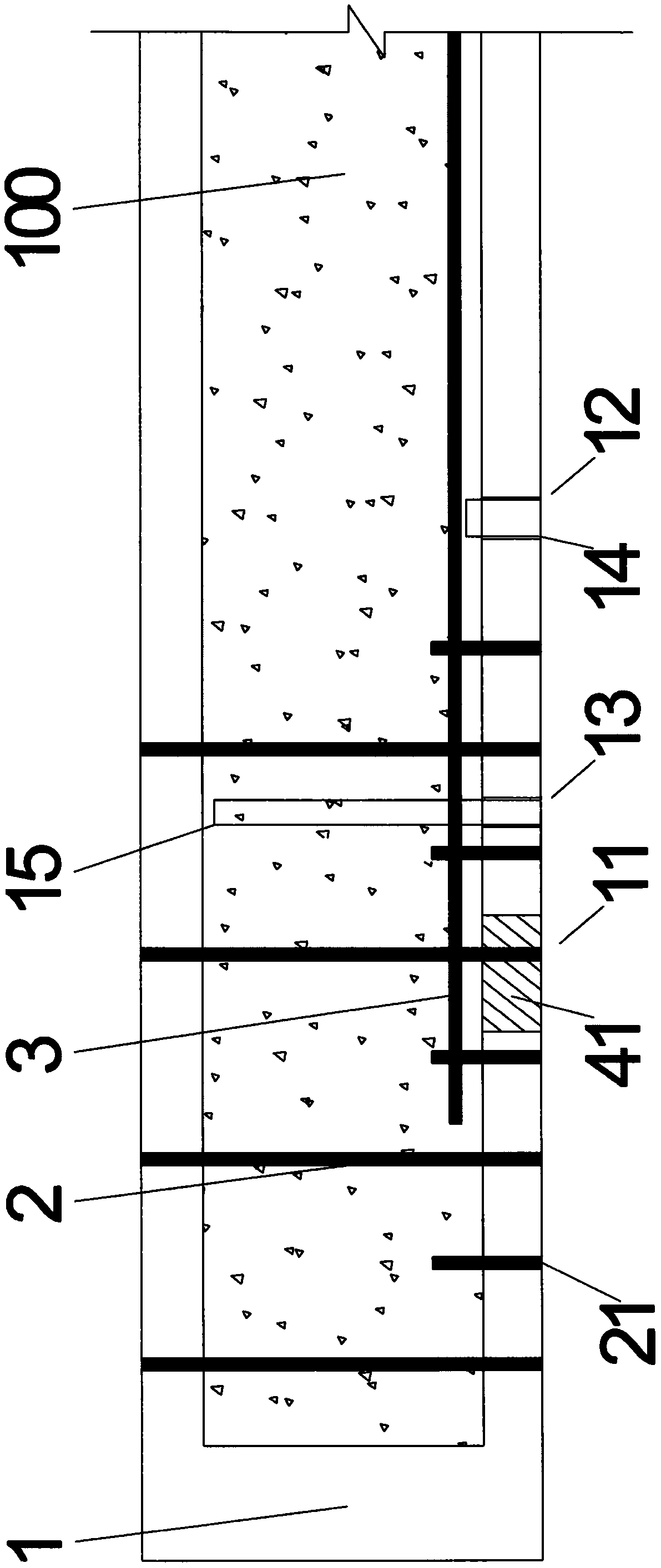

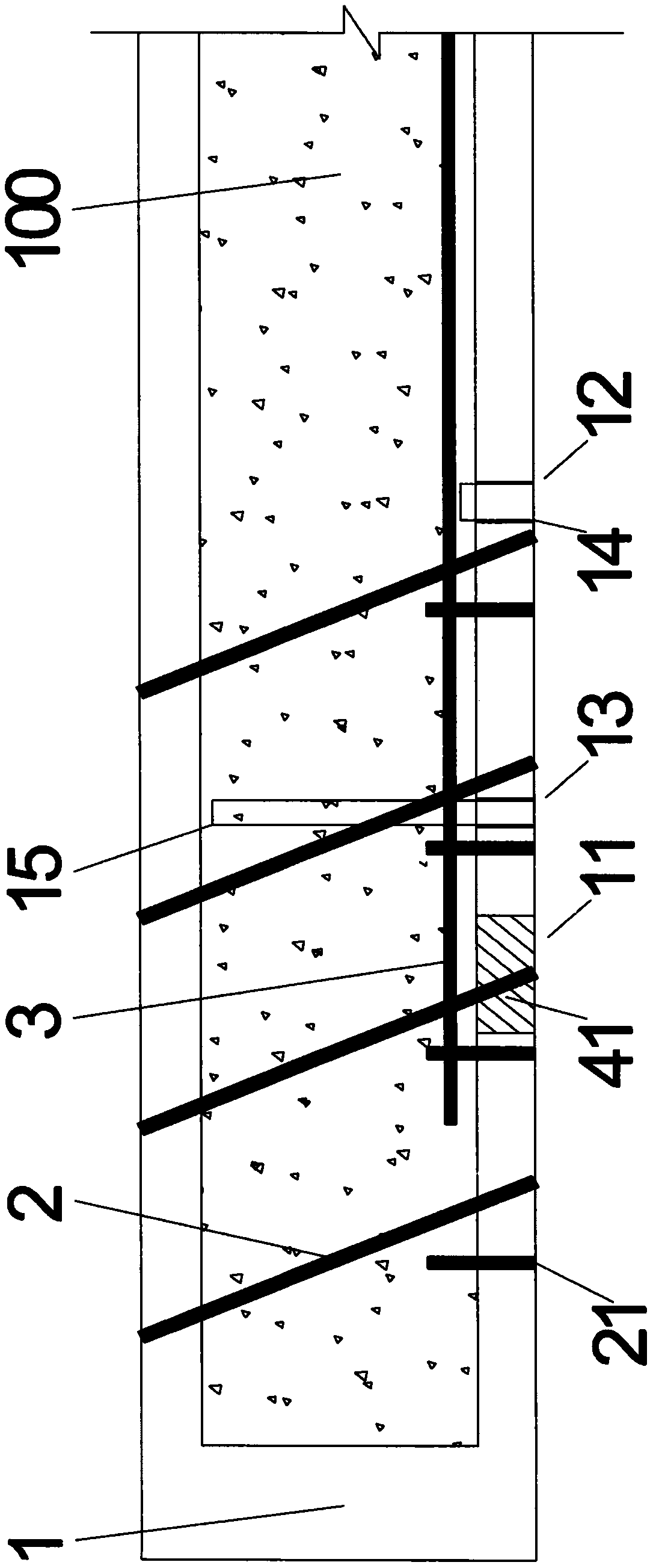

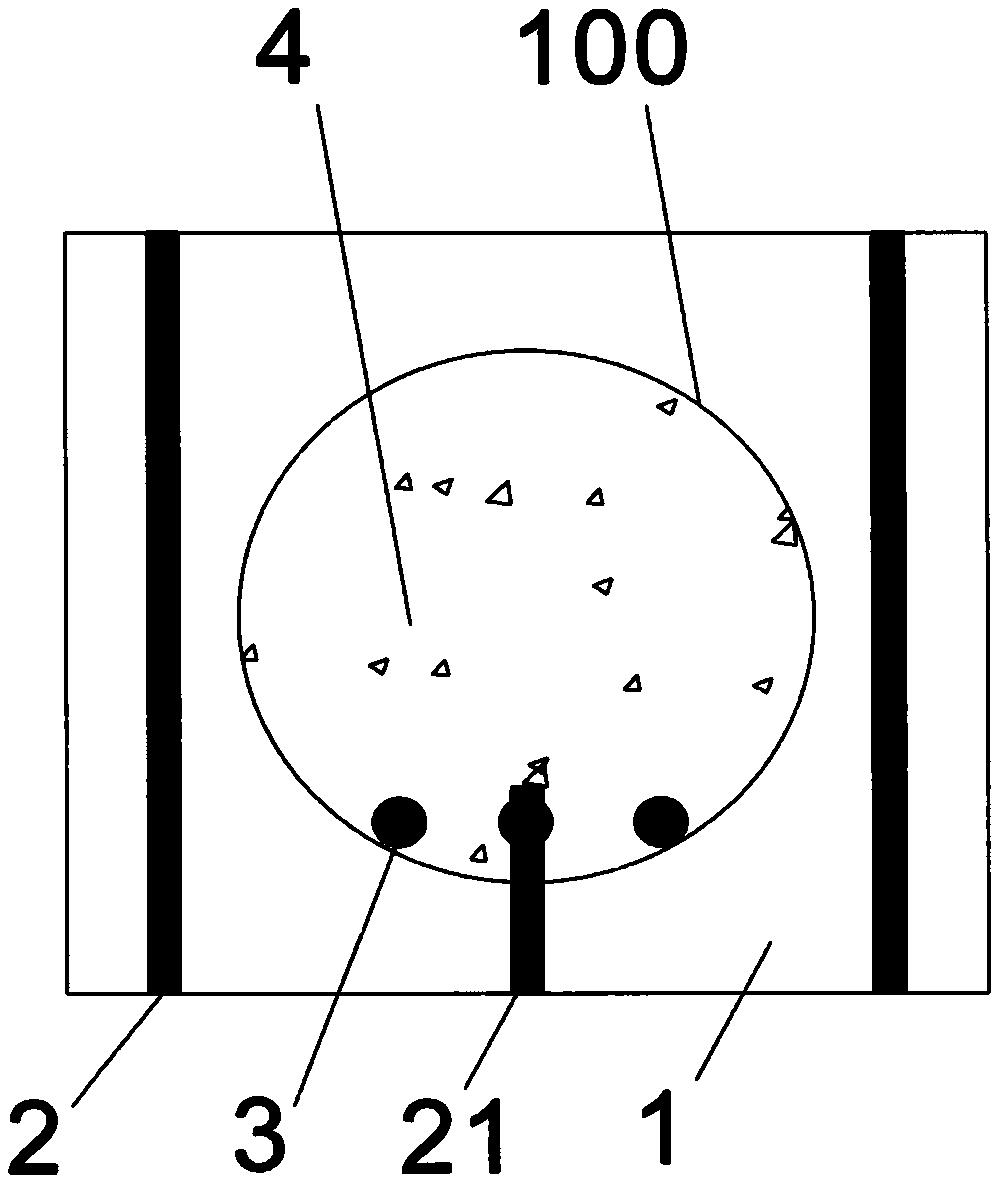

[0044] The present invention will be further described below in conjunction with the accompanying drawings. As shown in the accompanying drawings, a hollow-core slab bridge bending and shearing hybrid reinforcement method is characterized in that the bottom of the hollow-core slab bridge 1 is provided with a working channel 11, a perfusion hole 12 and an outlet The air hole 13 is connected to the cavity 100 of the hollow slab bridge 1, and the longitudinal steel bars 3 are arranged in the cavity 100 of the hollow slab bridge 1 along the axis direction of the hollow slab bridge 1 through the working tunnel 11, and the working hole is blocked with a plug 41 11. The filler 4 is filled into the cavity 100 of the hollow slab bridge 1 through the pouring hole 12. After the filler 4 is finally set, drill holes vertically or outwardly from the bottom up, and implant more than one row of shear steel bars 2 and fill it A number of connecting keys 21 are arranged between the object 4 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com