High-power dry-type capacitor

A capacitor and high-power technology, applied in the field of high-power dry capacitors, can solve the problems of energy storage capacity and large potential difference.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

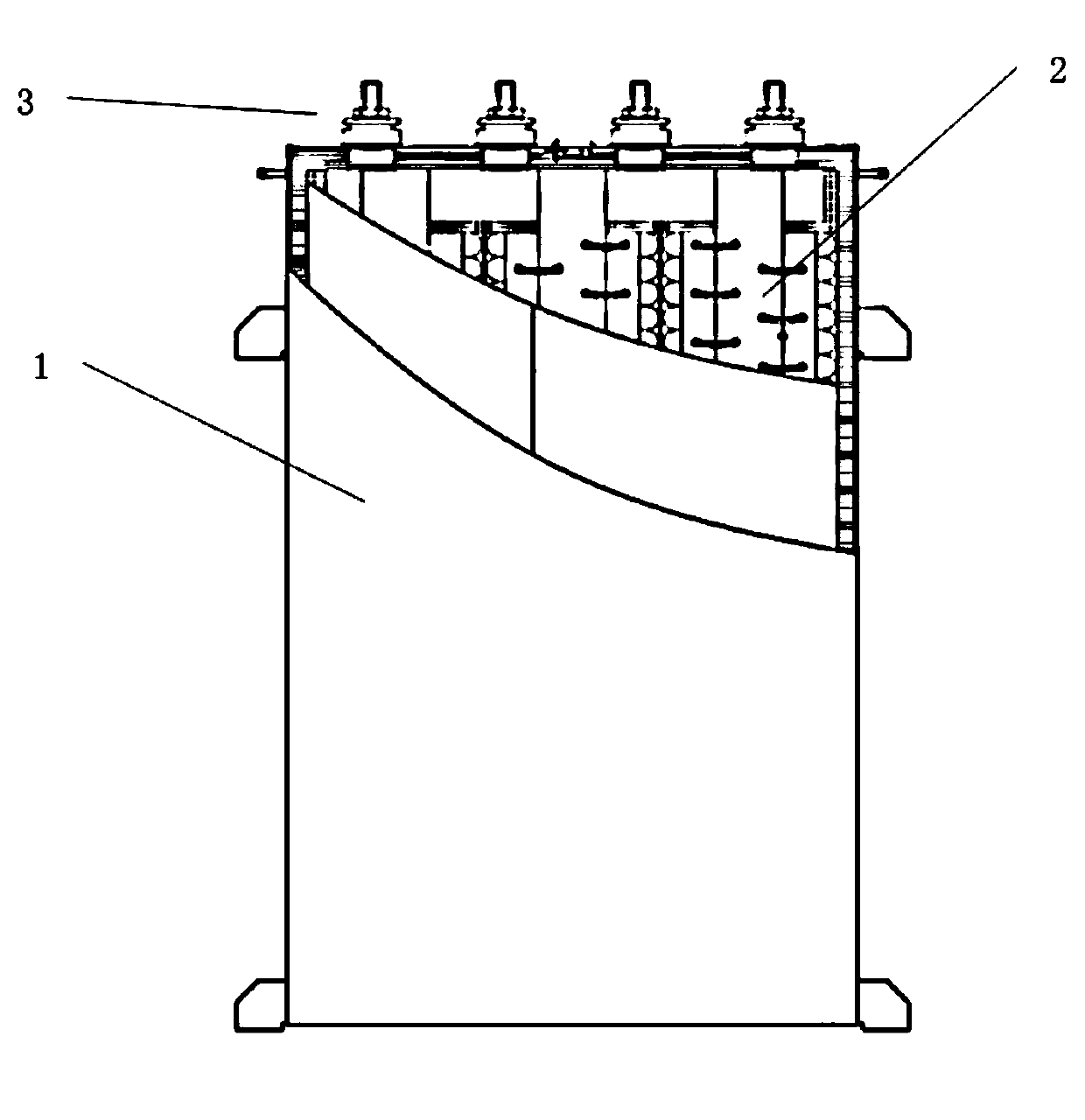

[0032] please see figure 1 Cooperate Image 6 The presented content, the present invention is about a high-power dry capacitor, characterized in that it includes:

[0033] Housing 1, high-power dry-type capacitor body 2, the high-power dry-type capacitor body 2 is arranged in the housing 1, the high-power dry-type capacitor body 2 includes a pole plate 21, and the pole plate 21 includes The substrate 21 is provided with a foamed nickel 212 on the surface of the substrate 211 , and a nickel-cobalt sulfide@nickel-molybdenum oxide core-shell structure 213 is provided on the surface of the foamed nickel 212 .

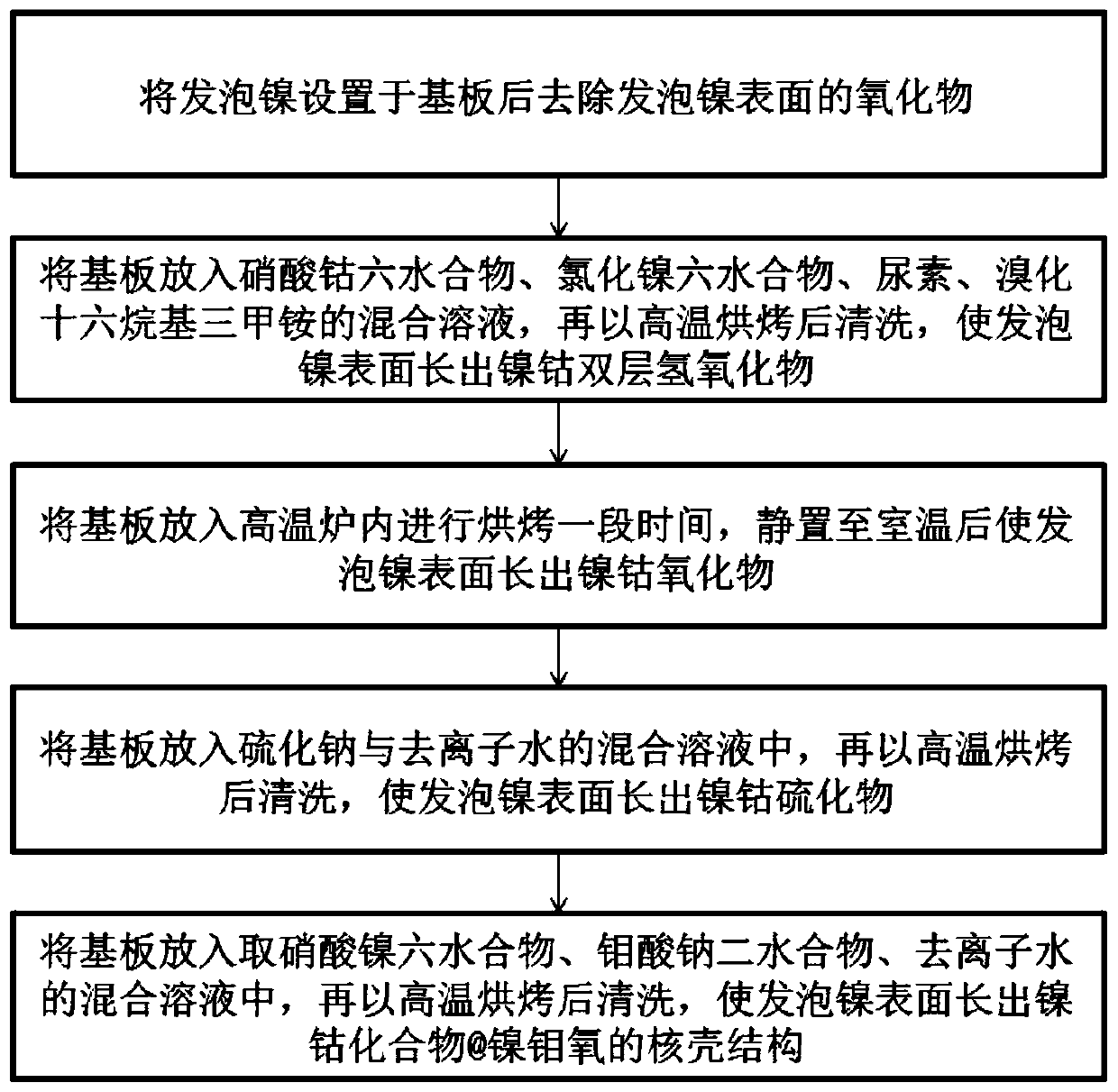

[0034] The manufacturing method of described pole plate 21 is:

[0035] (1) Treatment of foamed nickel:

[0036] After setting the foamed nickel 212 on the surface of the substrate 211, put it into a beaker together with acetone, and then use an ultrasonic oscillator to vibrate for a period of time, and then wash it with deionized water; the substrate 211 and Put the hy...

Embodiment 2

[0051] please see image 3 , the electrolyte of the high-power dry capacitor body is preferably a copolymerized polymer of polyacrylonitrile grafted block polyetherdiamine, and its production method is: first put the polyetherdiamine into a container with nitrogen and water , and then add cerium ammonium nitrate and nitric acid aqueous solution into the container, and then add the acrylonitrile into the container after the reaction is completed, and after standing for a period of time, finally obtain the polyacrylonitrile grafted block The copolymerized polymer of polyetherdiamine, and then the copolymerized polymer of polyacrylonitrile grafted block polyetherdiamine was washed several times with polymer water and acetone, and then placed in a ventilated place for drying. After completion, put it into dimethylamide for final purification and precipitation. In this way, using the polyacrylonitrile-grafted block polyetherdiamine copolymer polymer as a colloidal electrolyte has be...

Embodiment 3

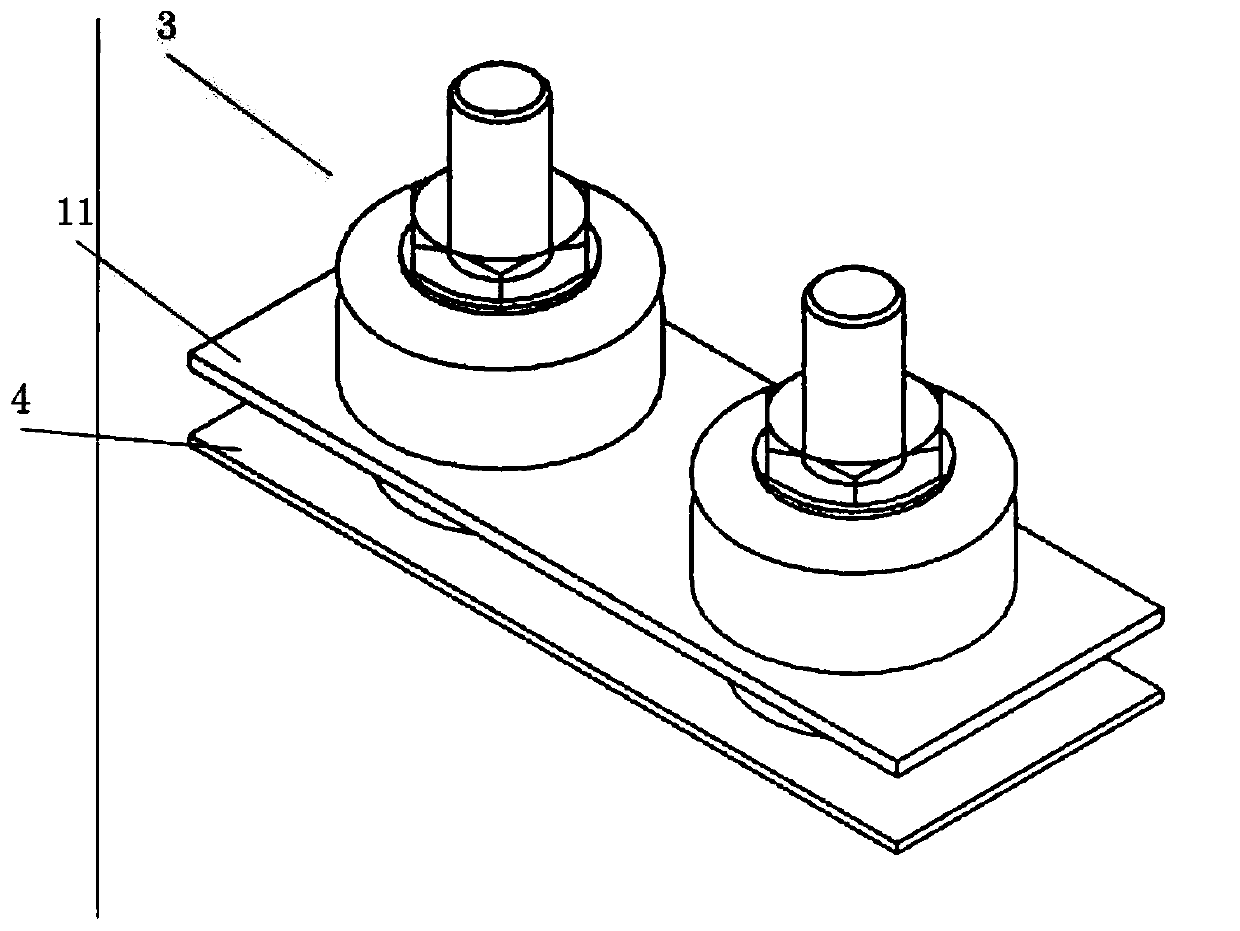

[0054] please see figure 2 The implementation method is: the surface of the housing 1 is provided with several conductive terminals 2 arranged in sequence at intervals, and each conductive terminal 2 is electrically connected to the high-power dry capacitor body 2 respectively, and the bottom of each conductive terminal 2 The ends pass through the top wall 11 of the housing 1 and the strip-shaped board 4 in sequence respectively, and there is a distance between the strip-shaped board 4 and the top wall 11 of the housing 1 .

[0055] In this way, through the spaced apart top wall 11 and strip-shaped plate body 4 , the conductive terminals 3 can be more stably arranged on the top surface of the housing 1 , and are not easily damaged by external force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com