Method for preparing Maillard reaction product from Chinese wolfberry extract, Maillard reaction product and application

A Maillard reaction and Lycium barbarum extract technology, applied in Maillard reaction products and application fields, can solve the problems of influence, strong volatility of aroma-causing substances, loss and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

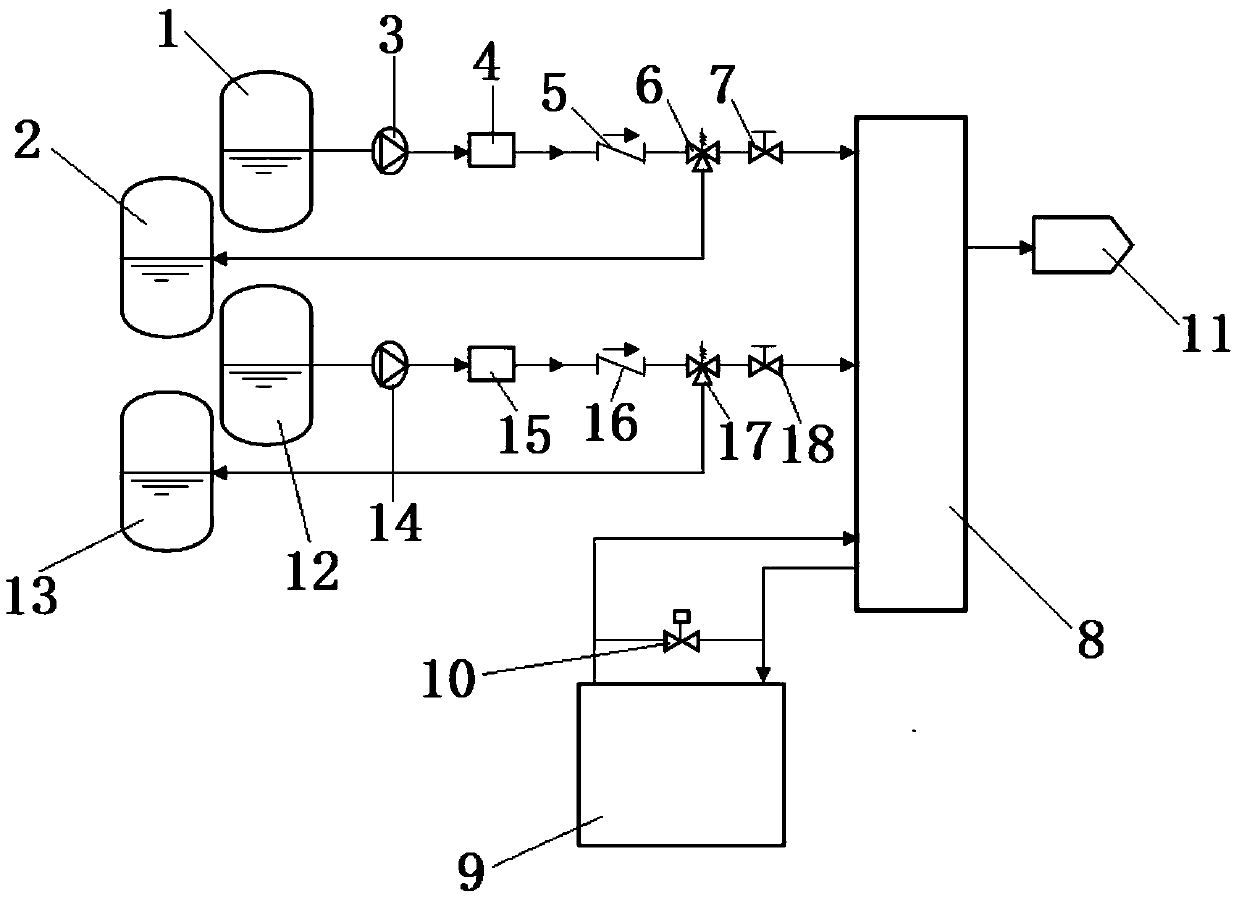

Image

Examples

Embodiment 1

[0072] The present embodiment carries out the preparation of Chinese wolfberry extract, comprises the following steps:

[0073] Frozen wolfberry pulp and crushed, weighed 500g wolfberry pulp and placed it in a 5L three-neck bottle, added 3L of 60% ethanol aqueous solution to soak for 24 hours, heated to 80°C for 2 hours under mechanical stirring, cooled to room temperature, and filtered to obtain wolfberry extract Mother liquor 1. Add 2 L of 40% ethanol aqueous solution to the filtrated fig residue, heat to 80° C. for 2 h under mechanical stirring, cool to room temperature, and filter to obtain wolfberry extract mother liquor 2. Lycium barbarum extract mother liquor 1 and mother liquor 2 were combined, concentrated under reduced pressure at 50° C. to obtain wolfberry extract.

Embodiment 2

[0075] The present embodiment carries out the preparation of Maillard reaction product, comprises the following steps:

[0076] Accurately weigh 200g wolfberry extract and 75g glycine, add 1L propylene glycol and water mixed solution, add while stirring, dissolve glucose and glycine in the mixed solution of propylene glycol and water under ultrasonic conditions at room temperature, cool to room temperature after the dissolution is complete, use Food grade NaOH was used to adjust the pH to 7. Insert the suction pipe of the online synthesis reaction system into the prepared reaction material, adjust the temperature of the constant temperature circulator to 160°C, and when the temperature of the online synthesis reaction system reaches 160°C, adjust the pressure of the online synthesis reaction system to 4bar , the flow rate of the reaction material was adjusted to 6.38mL / min, the reaction termination time was 10min, and the Maillard reaction product was collected at the outlet o...

Embodiment 3

[0078] The present embodiment carries out the preparation of Maillard reaction product, comprises the following steps:

[0079] Accurately weigh 200g of wolfberry extract, 40g of glycine and 60g of threonine, add 1L of propylene glycol and water mixed solution, add while stirring, dissolve glucose and glycine in the mixed solution of propylene glycol and water under ultrasonic conditions at room temperature, and wait for the solution to dissolve completely Cool to room temperature and adjust pH to 8 using food grade NaOH. Insert the suction pipe of the online synthesis reaction system into the prepared reaction material, adjust the temperature of the constant temperature circulator to 150°C, and when the temperature of the online synthesis reaction system reaches 150°C, adjust the pressure of the online synthesis reaction system to 4bar , the flow rate of the reaction material was adjusted to 6.38mL / min, the reaction termination time was 10min, and the Maillard reaction produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com