Packaging film, production line of packaging film and production process using production line

A packaging film and production line technology, applied in the production process, packaging film production line, packaging film field, can solve the problems of low production efficiency, short product life, easy to degumming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

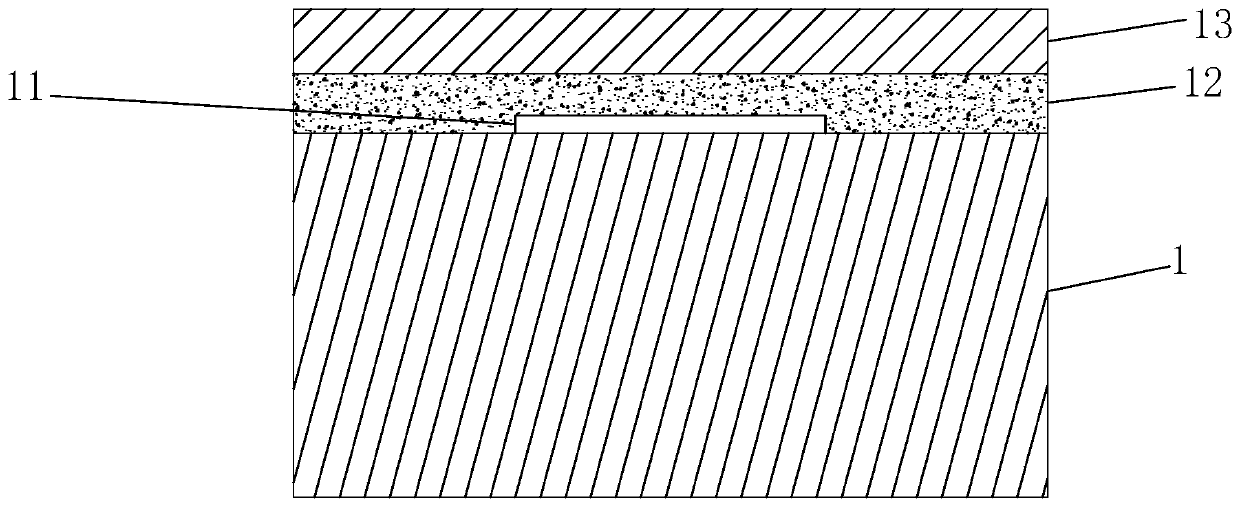

Embodiment 1

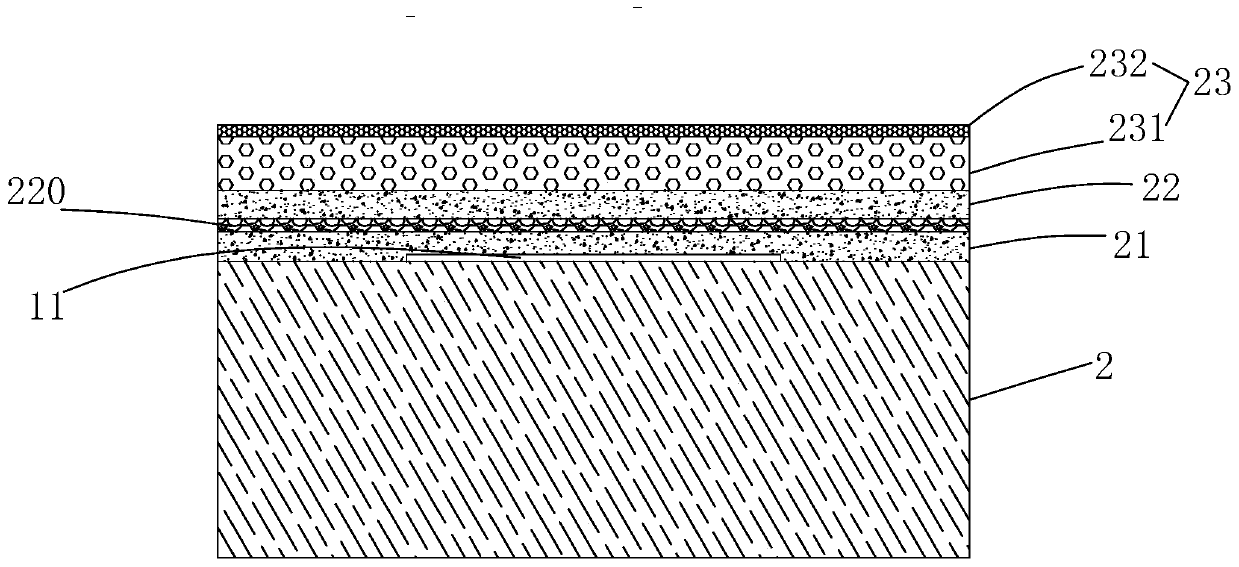

[0054] refer to figure 2 , is a kind of packaging film disclosed by the present invention, comprising a bottom film layer 2, a pattern layer 11 is formed on the surface of the bottom film layer 2 by gravure printing, and a first photosensitive adhesive layer positioned on the top of the pattern layer 11 is formed by scraping on the surface of the bottom film layer 2 21, the surface of the first photosensitive adhesive layer 21 is formed with a light stabilizer layer 220 to improve the anti-oxidation performance; the surface of the light stabilizer layer 220 is formed with a second photosensitive adhesive layer 22; the second photosensitive adhesive layer 22 is compounded with a gas exchange control The porous composite membrane layer 23. The porous composite film layer 23 includes a porous film layer 231 composited with the second photosensitive adhesive layer 22 and a dense film layer 232 integrally formed on the surface of the porous film layer 231. The porous composite fil...

Embodiment 2

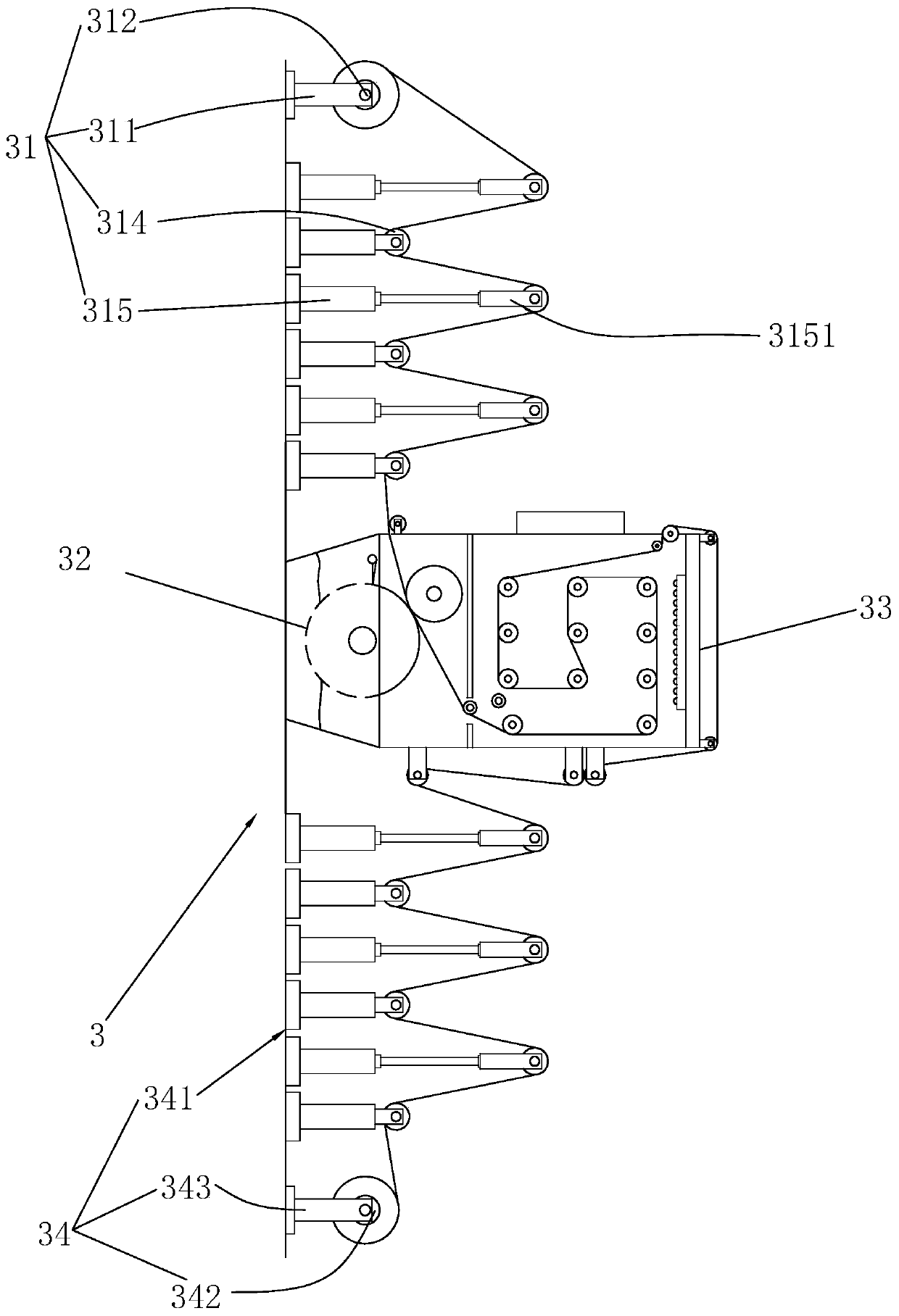

[0056] refer to image 3 and Figure 5 , a production line for packaging films, comprising a gravure printing device 3 for printing a pattern layer 11 on the surface of a base film layer 2, a first glue scraper for forming a first photosensitive adhesive layer 21 on the surface of a porous composite film layer 23 Coating device 4, the first glue scraping device 4 is connected with the light stabilizer adding device 5 that is used to form light stabilizer layer 220 on the surface of the first photosensitive glue layer 21; 220 surface forms the second glue scraping device 6 of the second photosensitive adhesive layer 22; The second glue scraping device 6 is connected with the composite device 7 that is used for composite porous composite film layer 23 and base film layer 2; Composite device 7 is connected with light The curing device 8, the photocuring device 8 makes the first photosensitive adhesive layer 21 and the second photosensitive adhesive layer 22 photocrosslinked and ...

Embodiment 3

[0064] A production process utilizing a packaging film production line, comprising the following steps:

[0065] Step 1: Preparation of semi-finished product A, the roll shaft with the base film layer 2 fixed on the base film roll 312, first enters the first adjustment component 313 for unwinding, and then enters the printing mechanism 32 to gravure the required pattern on the base film layer 2 , then enter the drying chamber 331, dry for 10 minutes to form the pattern layer 11, and finally wind up the semi-finished product A by the winding mechanism 34;

[0066] Step 2: preparation of semi-finished product B;

[0067] Step 2.1: The roll shaft with the porous composite film layer 23 is fixed to the second unwinding mechanism 41, unwinds, and enters the first light-shielding shell 43 through the introduction roller 44, and the photosensitive glue in the glue storage bucket 401 passes through the glue dropper 404 Evenly drop on the surface of the porous composite membrane layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com