A highly adaptable viscosity-reducing polycarboxylate water reducer and its preparation method and application

一种减水剂、适应性的技术,应用在高适应性降粘型聚羧酸减水剂及其制备领域,能够解决无法降低高强混凝土粘度、不利工业化规模生产、性能提升不明显等问题,达到减水率高、时间短、保坍性能好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

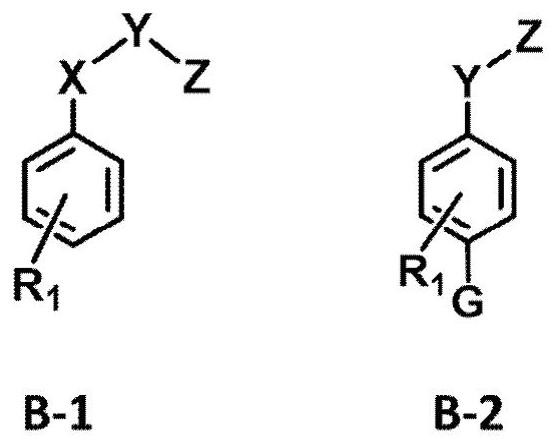

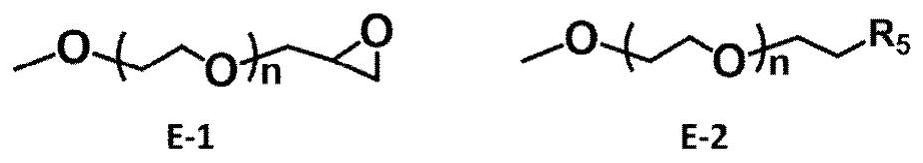

Method used

Image

Examples

Embodiment 1

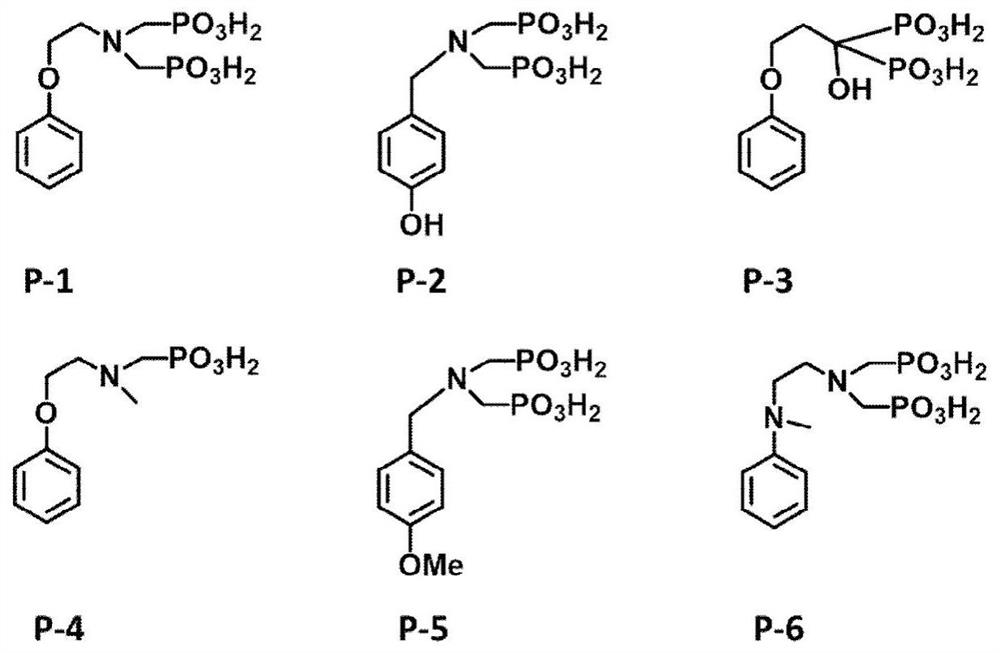

[0051] (1) Preparation of the main chain: In a four-necked flask equipped with a thermometer and a mechanical stirrer, add 138g (1.0mol) of o-hydroxybenzoic acid, 65g (0.20mol) of phenylphosphoric acid monomer P-1, and ethylenediamine 6g (0.10mol) and 100g of water, mix well, put the flask into a constant temperature oil bath at 100°C, then add 114g (1.4mol) of 37% formaldehyde solution dropwise to the flask, dropwise for 1h, keep warm after dropping After 7 hours of reaction, the main chain polymer can be obtained;

[0052] (2) Introduction of side chains: lower the temperature of the reaction flask to 30°C, then add 900 g (0.18 mol) of epoxy group-terminated polyether macromonomers with a molecular weight of 5000 at one time, keep the reaction for 2 hours, add 1200 g of water to dilute, Obtain the highly adaptable viscosity-reducing polycarboxylate water reducer, tested by GPC, the weight average molecular weight M w It is 39200, and the molecular weight distribution coeffi...

Embodiment 2

[0054] (1) Preparation of the main chain: In a four-necked flask equipped with a thermometer and a mechanical stirrer, add 138g (1.0mol) of m-hydroxybenzoic acid, 124.8g (0.40mol) of phenylphosphoric acid monomer P-2, Mix 6g (0.10mol) of amine and 160g of water evenly, put the flask into a constant temperature oil bath at 100°C, then add 130g (1.6mol) of 37% formaldehyde solution dropwise to the flask, dropwise for 1h, and keep the temperature for 7h. The main chain polymer can be obtained;

[0055] (2) Introduction of side chains: lower the temperature of the reaction flask to 40°C, then add 600 g (0.15 mol) of an epoxy group-terminated polyether macromonomer with a molecular weight of 4000 at one time, keep the reaction for 2 hours, add 850 g of water to dilute, Obtain the highly adaptable viscosity-reducing polycarboxylate water reducer, tested by GPC, the weight average molecular weight M w It is 34200, and the molecular weight distribution coefficient is 2.42.

Embodiment 3

[0057] (1) Preparation of the main chain: In a four-necked flask equipped with a thermometer and a mechanical stirrer, add 138g (1.0mol) of p-hydroxybenzoic acid, 249.6g (0.80mol) of phenylphosphoric acid monomer P-3, diethylene 30.9g (0.30mol) of triamine and 100g of water, mix evenly, put the flask into a constant temperature oil bath at 100°C, then add 262g (2.2mol) of 37% acetaldehyde solution dropwise to the flask, dropwise for 1h, keep warm After reacting for 9 hours, the main chain polymer can be obtained;

[0058] (2) Introduction of side chains: lower the temperature of the reaction flask to 50°C, then add 2400 g (0.60 mol) of epoxy group-terminated polyether macromonomer with a molecular weight of 4000 at one time, keep the reaction for 2 hours, add 2650 g of water to dilute, Obtain the highly adaptable viscosity-reducing polycarboxylate water reducer, tested by GPC, the weight average molecular weight M w It is 30500, and the molecular weight distribution coefficie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com