Preparation process of piperacillin sodium

A technology of piperacillin sodium and preparation process, applied in the direction of organic chemistry and the like, can solve the problems such as the impurity of piperacillin sodium cannot be removed by crystallization, the occurrence of degradation products, the appearance of easy discoloration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

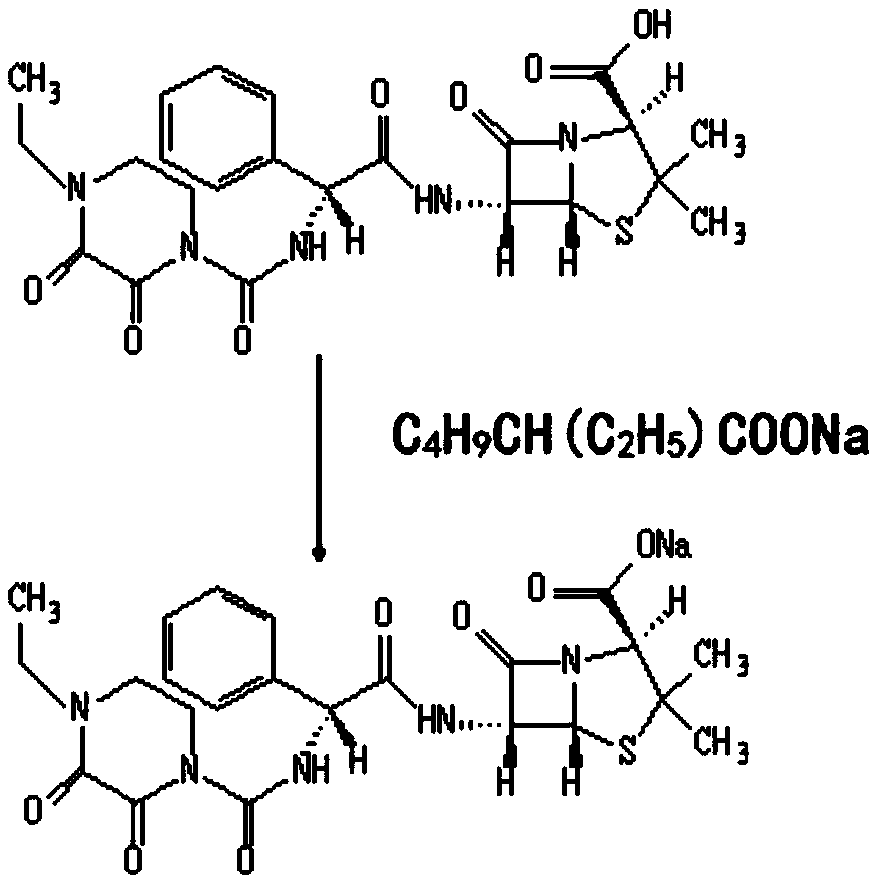

Method used

Image

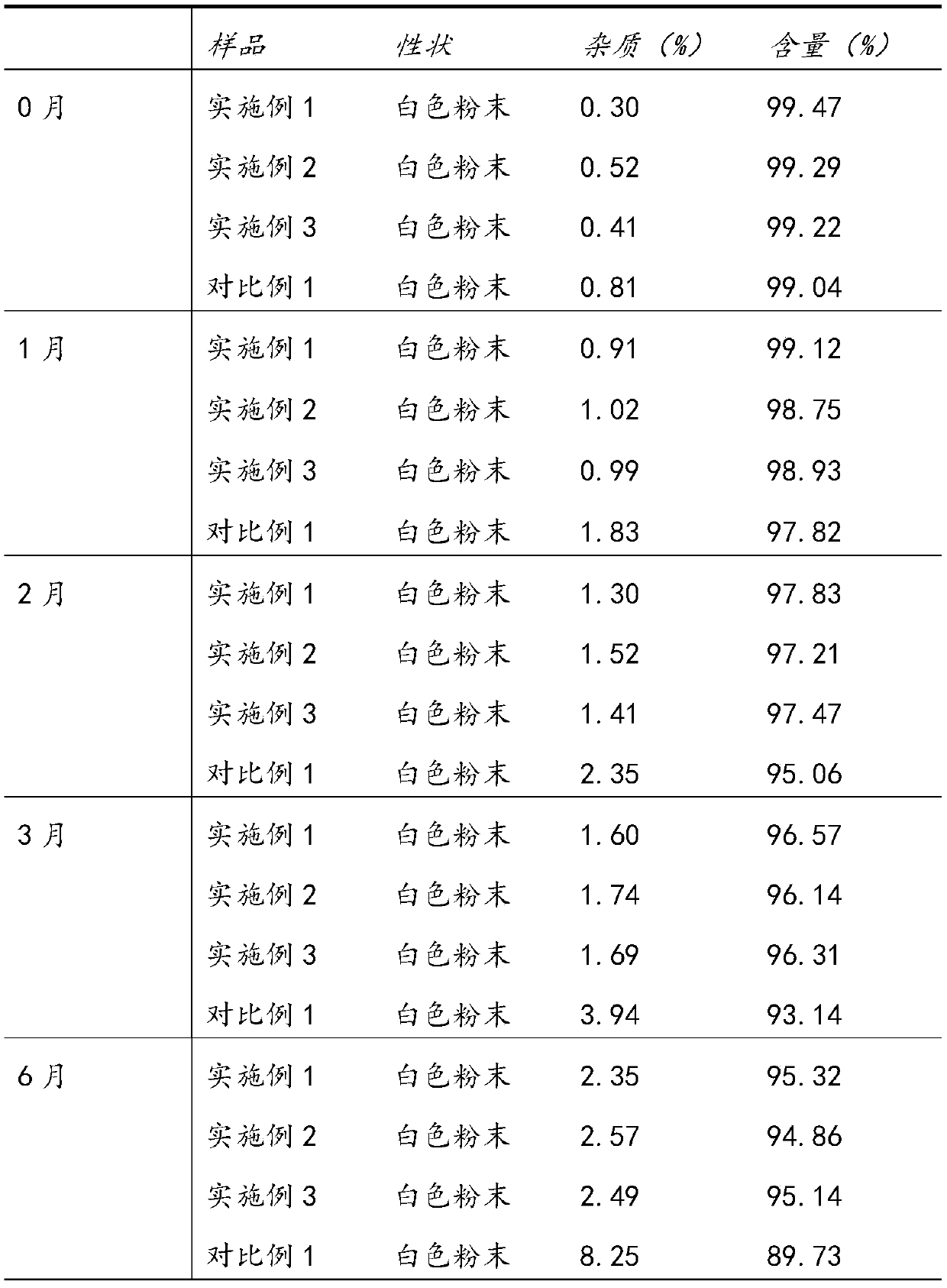

Examples

Embodiment 1

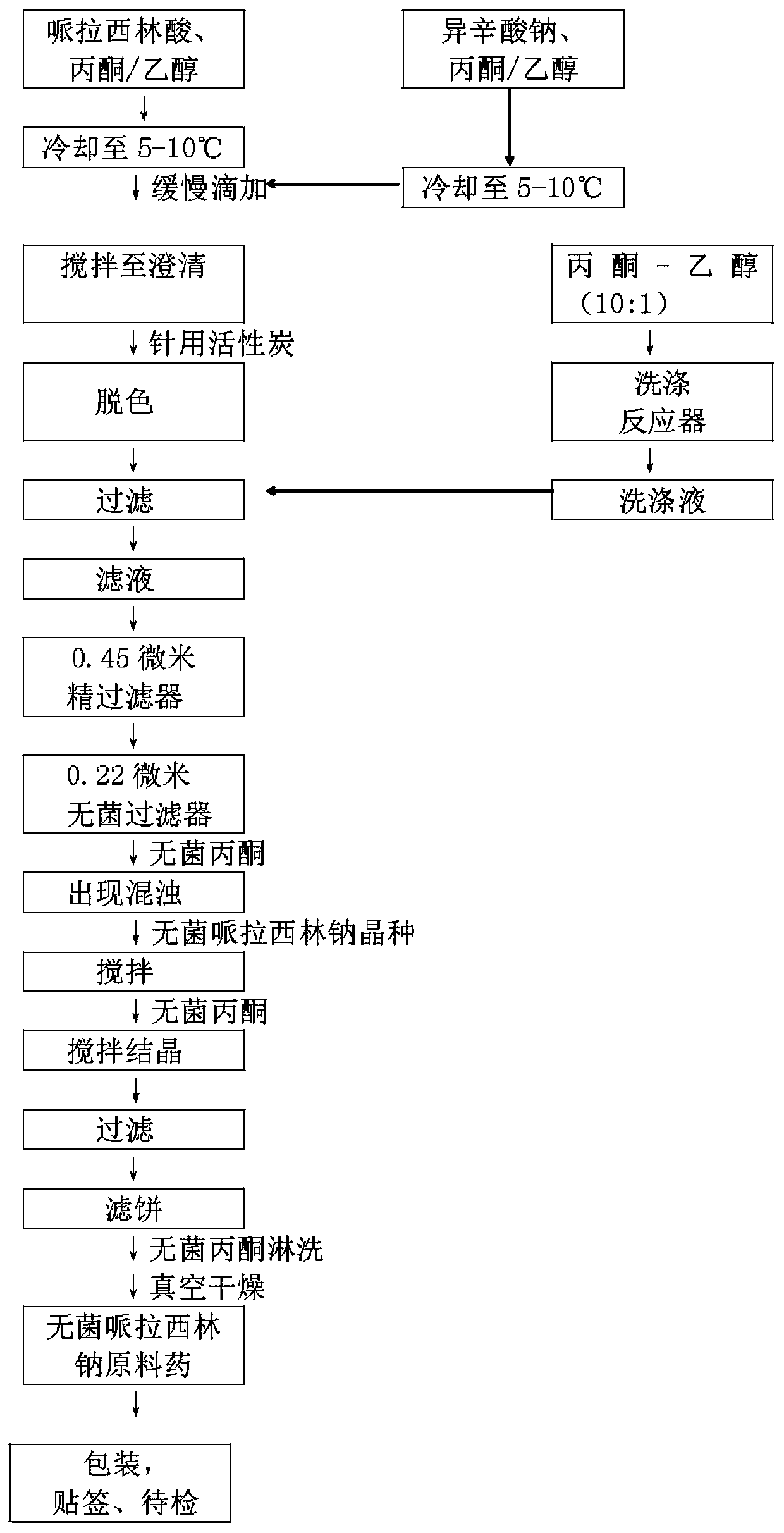

[0044] (1) Add 100L of acetone, 25L of absolute ethanol, and 20kg of piperacillin acid into the reaction tank, stir to dissolve, and cool to 5-10°C;

[0045] (2) Add 6.53Kg of sodium isooctanoate, 50L of acetone and 5L of absolute ethanol to the configuration tank, stir to dissolve, cool to 5-10°C, slowly add to the acid solution for about 60 minutes, and stir until the solution is clear and transparent;

[0046] (3) Add 2Kg of active carbon for needles, decolorize at room temperature for 30 minutes, and filter; wash the reaction tank with 30L of acetone: absolute ethanol = 10:1 (v / v) mixed solution, filter the washing liquid, and combine the filtrates;

[0047] (4) The filtrate is aseptically filtered through filters of 0.45 μm and 0.22 μm pore size, pressed into a crystallization tank in a sterile room, and 80 L of sterile acetone is added dropwise, and when turbidity occurs, a small amount of sterile piperacillin sodium seeds are added and stirred for 1 hour , continue to s...

Embodiment 2

[0050] (1) Add 100L of acetone, 25L of absolute ethanol, and 20kg of piperacillin acid into the reaction tank, stir to dissolve, and cool to 5-10°C;

[0051] (2) Add 4Kg of sodium isooctanoate, 50L of acetone and 5L of absolute ethanol to the configuration tank, stir to dissolve, cool to 5-10°C, slowly add dropwise to the acid solution for about 60 minutes, and stir until the solution is clear and transparent;

[0052] (3) Add 2Kg of active carbon for needles, decolorize at room temperature for 30 minutes, and filter; wash the reaction tank with 30L of acetone: absolute ethanol = 10:1 (v / v) mixed solution, filter the washing liquid, and combine the filtrates;

[0053] (4) The filtrate is aseptically filtered through filters of 0.45 μm and 0.22 μm pore size, pressed into a crystallization tank in a sterile room, and 80 L of sterile acetone is added dropwise, and when turbidity occurs, a small amount of sterile piperacillin sodium seeds are added and stirred for 1 hour , continu...

Embodiment 3

[0056] (1) Add 100L of acetone, 25L of absolute ethanol, and 20kg of piperacillin acid into the reaction tank, stir to dissolve, and cool to 5-10°C;

[0057] (2) Add 10Kg sodium isooctanoate, 50L acetone and 5L absolute ethanol to the configuration tank, stir to dissolve, cool to 5-10°C, slowly add dropwise to the acid solution for about 60 minutes, and stir until the solution is clear and transparent;

[0058] (3) Add 2Kg of active carbon for needles, decolorize at room temperature for 30 minutes, and filter; wash the reaction tank with 30L of acetone: absolute ethanol = 10:1 (v / v) mixed solution, filter the washing liquid, and combine the filtrates;

[0059] (4) The filtrate is aseptically filtered through filters of 0.45 μm and 0.22 μm pore size, pressed into a crystallization tank in a sterile room, and 80 L of sterile acetone is added dropwise, and when turbidity occurs, a small amount of sterile piperacillin sodium seeds are added and stirred for 1 hour , continue to slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com