A kind of start-up preparation method of hydrotreating unit

A technology of hydroprocessing and preparation methods, which is applied in the fields of start-up of hydroprocessing operations, treatment of hydrocarbon oil, petroleum industry, etc., to achieve the effect of reducing the difficulty and danger of operations, reducing risks, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

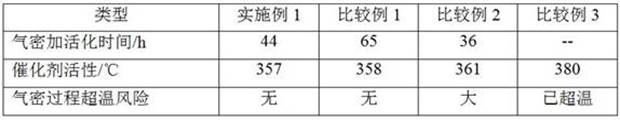

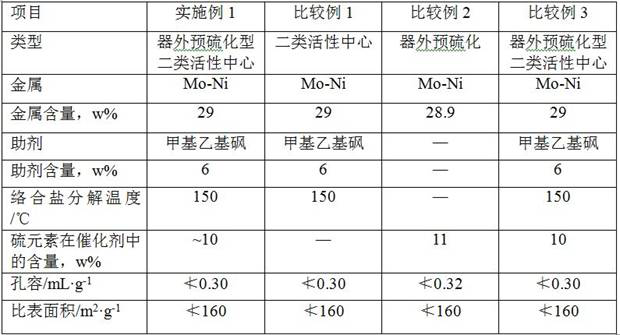

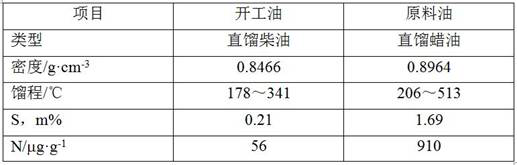

[0041]A certain hydrogenation unit is equipped with an external pre-sulfurized type 2 active center hydroprocessing catalyst. The properties of the catalyst are shown in Table 2, and the system design pressure is 12MPa. Preparation and start-up process include:

[0042](1) Nitrogen is introduced into the reaction system, followed by low pressure airtight at 1.0Pa, 3.0MPa, and 5.0MPa;

[0043](2) After the airtightness is qualified, after the system pressure is reduced to 2.7MPa, hydrogen is introduced to keep the pressure constant at 3.4MPa, and then the catalyst bed temperature is raised to 100°C for 4 hours; the heating rate is 20°C / h;

[0044](3) Keep the pressure constant, continue to increase the catalyst bed temperature to 120°C for 4 hours at a rate of ~7°C / h;

[0045](4) Continue to increase the catalyst bed temperature to 140°C at a rate of ~7°C / h, and keep it constant;

[0046](5) When the reactor wall temperature is greater than 120°C, the maximum temperature rise of the catalyst bed is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com