Method for producing DHA by fermentation of schizochytrium limacinum

A technology of Schizochytrium and fermentation liquid, which is applied in the field of DHA production by fermentation of Schizochytrium, and can solve the problems of low production efficiency, contamination, complicated production line and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

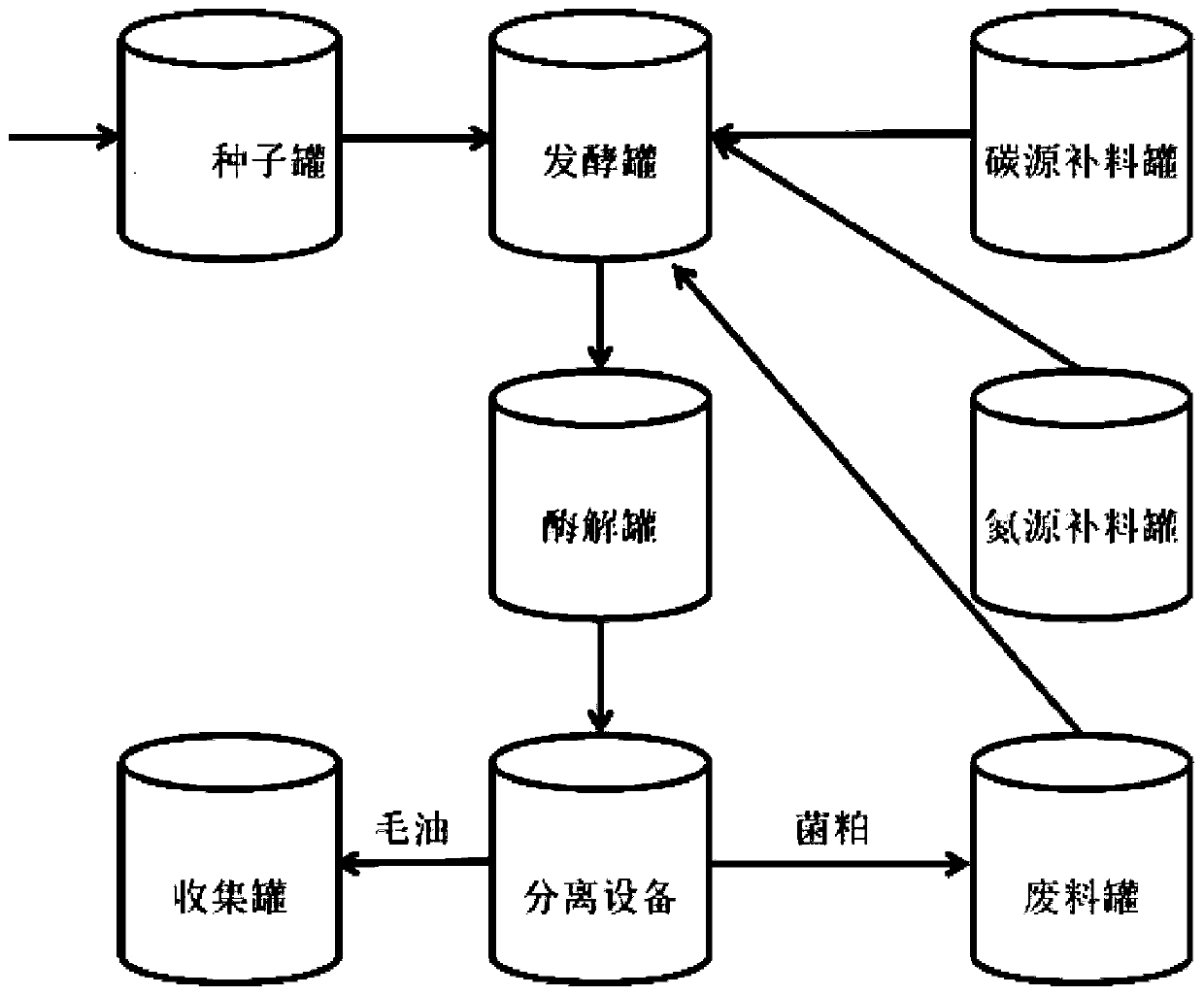

Image

Examples

Embodiment 1

[0074] The present embodiment provides a kind of method that Schizochytrium produces DHA, comprises steps as follows:

[0075] (1) Activation, expansion and fermentation of Schizochytrium: the preserved Schizochytrium CABIO-A-2-II (Schizochytrium sp.CABIO-A-2-II) (its preservation number is CCTCC NO: M2019990 ; The preservation address is China Center for Type Culture Collection (CCTCC), China, Wuhan, Wuhan University, postcode: 430070; the preservation date is December 2, 2019) After being cultured on activated medium, it was transferred to the seed tank for expansion , the expansion temperature is 30°C, and the culture is continued for 60 hours to obtain the seed liquid; then the seed liquid is inoculated into the fermenter, after the inoculation is completed, the fermenter contains 36L of fermentation liquid, and the fermentation is continued at 30°C for 96h;

[0076](2) Feed 18L of fermented liquid into the enzymolysis tank, inactivate it and cool it down to 55°C, add sodi...

Embodiment 2

[0081] The present embodiment provides a kind of method that Schizochytrium produces DHA, comprises steps as follows:

[0082] (1) Activation, expansion and fermentation of Schizochytrium: the preserved Schizochytrium was cultured in an activated medium and then transferred to a seed tank for expansion. The expansion temperature was 28°C for 72 hours to obtain seeds Then inoculate the seed liquid into the fermenter. After the inoculation, the fermenter contains 40L of fermented liquid, and continue to ferment at 30°C for 72h;

[0083] (2) Feed 28L of fermentation broth into the enzymolysis tank, inactivate and cool down to 55°C, adjust the pH to 7.0, and then add a final concentration of 0.7% protease (500,000 U / g) and 0.3% cellulase (10,000 U / g) enzymolysis for 10 hours to obtain enzymolysis solution;

[0084] Discharge the enzymatic solution into the three-phase drum centrifuge, collect the DHA crude oil into the collection tank, and discharge the bacteria residue into the ...

Embodiment 3

[0088] The present embodiment provides a kind of method that Schizochytrium produces DHA, comprises steps as follows:

[0089] (1) Activation, expansion and fermentation of Schizochytrium: the preserved Schizochytrium was cultured in an activated medium and then transferred to a seed tank for expansion. The expansion temperature was 25°C for 48 hours to obtain seeds After the inoculation, the fermenter contains 36L of fermentation broth, and the fermentation is continued at 25°C for 96h;

[0090] (2) After fermentation, 14.4L of fermented liquid is fed into the enzymolysis tank, cooled to 60°C after inactivation, and then added with a final concentration of 0.6% protease (500,000 U / g) and 0.2% cellulase (1 10,000 U / g) enzymolysis for 10 hours to obtain the enzymolysis solution; discharge the enzymolysis solution into a three-phase drum centrifuge, collect DHA crude oil to a collection tank, and discharge the bacterial meal to a waste tank for use;

[0091] (3) the remaining 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com