A kind of cemented carbide with gradient structure rich in surface layer binder phase and its preparation method

A cemented carbide and gradient structure technology, applied in the field of powder metallurgy, can solve the problems of chipping, low binder content in the surface layer and toughening effect, etc., and achieve the effect of increasing the cost of raw materials, wide application range and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

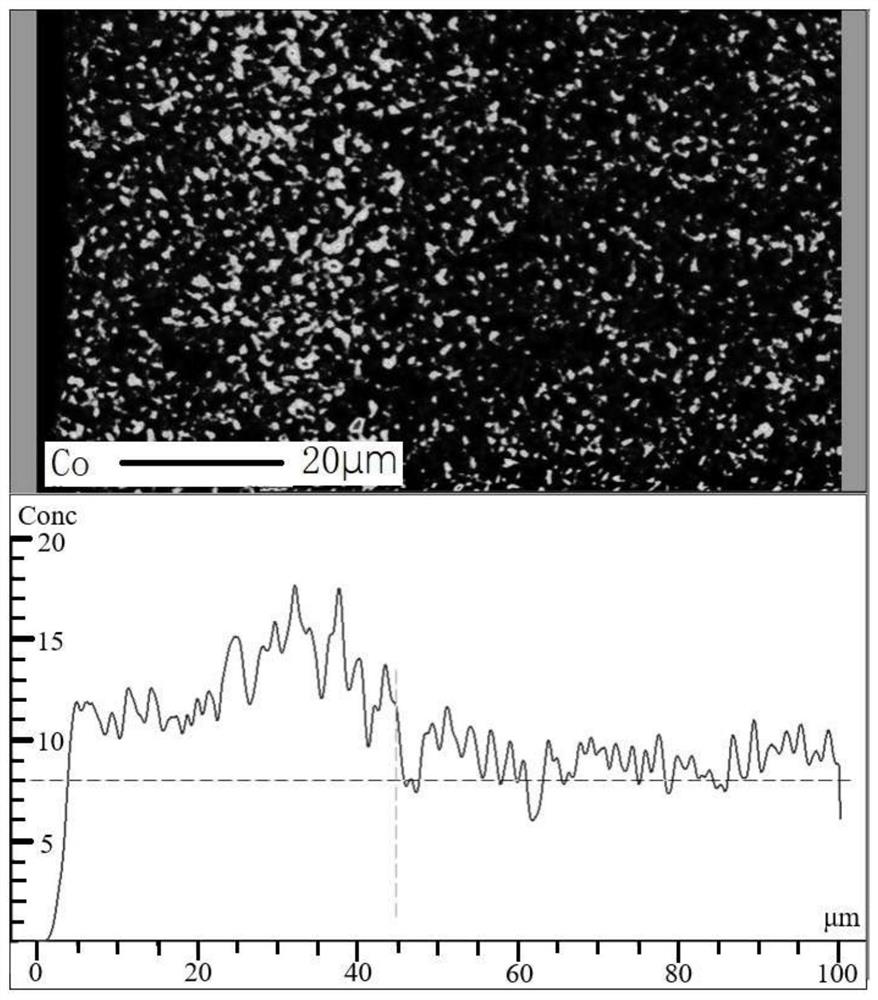

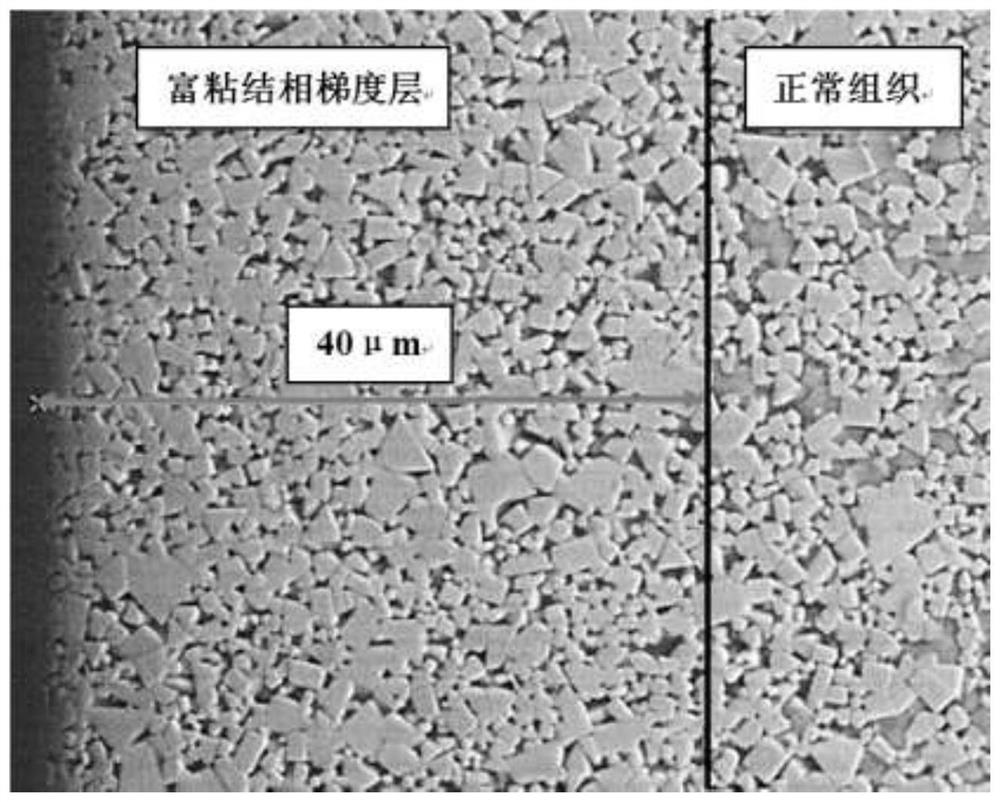

[0045] A kind of cemented carbide of the present invention has surface layer rich binder phase gradient structure, described cemented carbide is made of WC, Co, Re, TaC, NbC, TiC, TiC 0.5 N 0.5 composition. The mass percentage of each substance in the cemented carbide is: WC 79.5%, Co 8%, Re 0.5%, TaC 5%, NbC 3%, TiC 2%, TiC 0.5 N 0.5 2%. The thickness of the binder-rich gradient structure is 40 μm, and the content of the binder phase at 0-20 μm away from the alloy surface is evenly distributed, about 11%, which is 137.5% of the nominal content of 8%. The binder phase at 20-32 μm away from the alloy surface The junction phase content is evenly distributed, about 15%, which is 188% of the nominal content of 8%. Lower, here the transition layer between the gradient layer and the core tissue (normal tissue). Such as figure 1 Shown is the binder phase distribution map (EPMA) in the 100 μm region of the cemented carbide surface of the embodiment of the present invention. Suc...

Embodiment 2

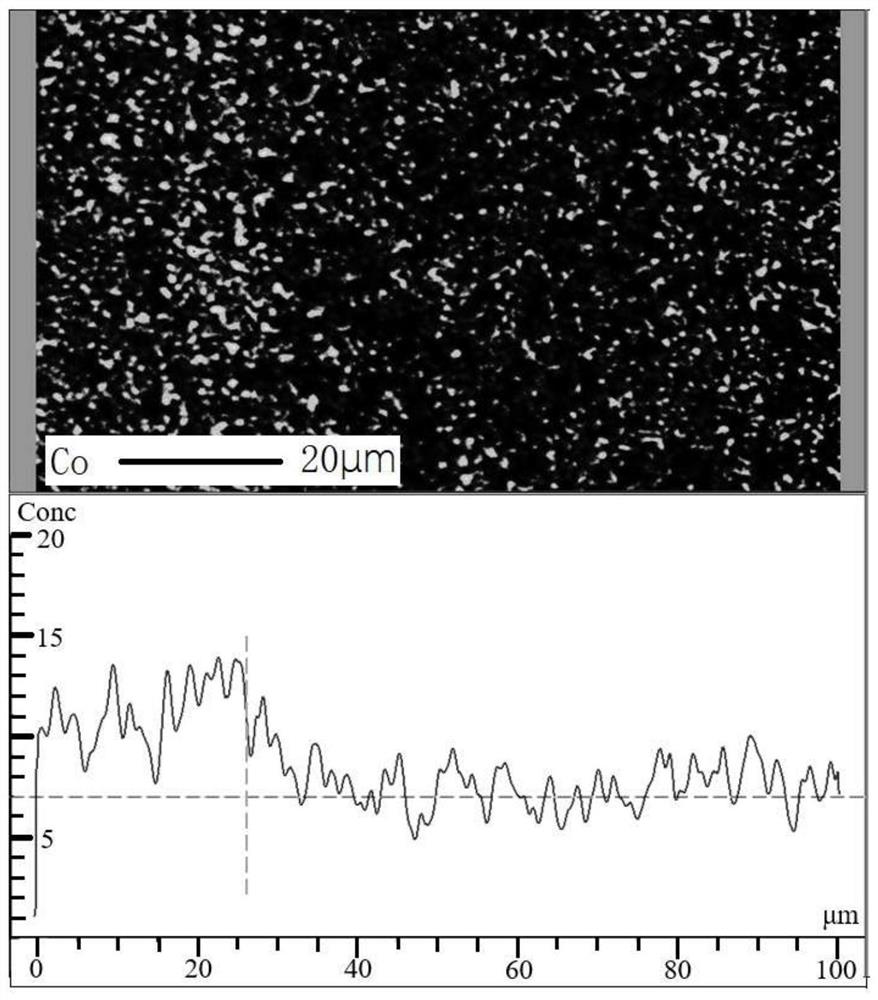

[0053] A kind of cemented carbide of the present invention has surface layer rich binder phase gradient structure, described cemented carbide is made of WC, Co, TaC, NbC, TiC, TiC 0.5 N 0.5 composition. The mass percentage of each substance in the cemented carbide is: WC 83%, Co 7%, TaC 4%, NbC 2%, TiC 3%, TiC 0.5 N 0.5 1%. The thickness of the binder-rich gradient structure is 25 μm, and the content of the binder phase at 0-15 μm from the alloy surface is evenly distributed, about 10%, which is 143% of the nominal content of 7%. The binder phase at 15-25 μm from the alloy surface The content of the binding phase is evenly distributed, about 12.5%, which is 178.5% of the nominal content of 7%, and the content of the binding phase decreases rapidly at a distance of 25-30 μm from the alloy surface, which is between the gradient layer and the core tissue (normal tissue) transition layer. Such as image 3 Shown is the binder phase distribution map (EPMA) in the 100 μm region...

Embodiment 3

[0060] A kind of cemented carbide of the present invention has surface rich binder phase gradient structure, described cemented carbide is made of WC, Co, Ni 3 Al, B, TaC, TiC, TiC 0.5 N 0.5 composition. The mass percentage of each substance in cemented carbide is: WC accounts for 84.95%, Co accounts for 8%, Ni 3 Al accounted for 1%, B accounted for 0.05%, TaC accounted for 2%, TiC accounted for 3.5%, TiC 0.5 N 0.5 0.5%. The thickness of the gradient structure rich in binder phase is 47 μm, and the content of binder phase at 0-20 μm away from the alloy surface gradually increases from 9.6% to 13%, which is 120-162% of the nominal content of 8%, and 20% away from the alloy surface The binder phase content at -47μm is evenly distributed, about 14.0%, which is 175% of the nominal content of 8%, and the binder phase content decreases rapidly at 47-50μm from the alloy surface, where the gradient layer and the core structure ( transition layer between normal tissues). Such as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com