Method for synthesizing polycrystalline diamond by dry distillation of plant straw detonation

A technology of polycrystalline diamond and plant straw is applied in the field of synthetic diamond to achieve the effect of complete lattice, good performance index and large grain size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

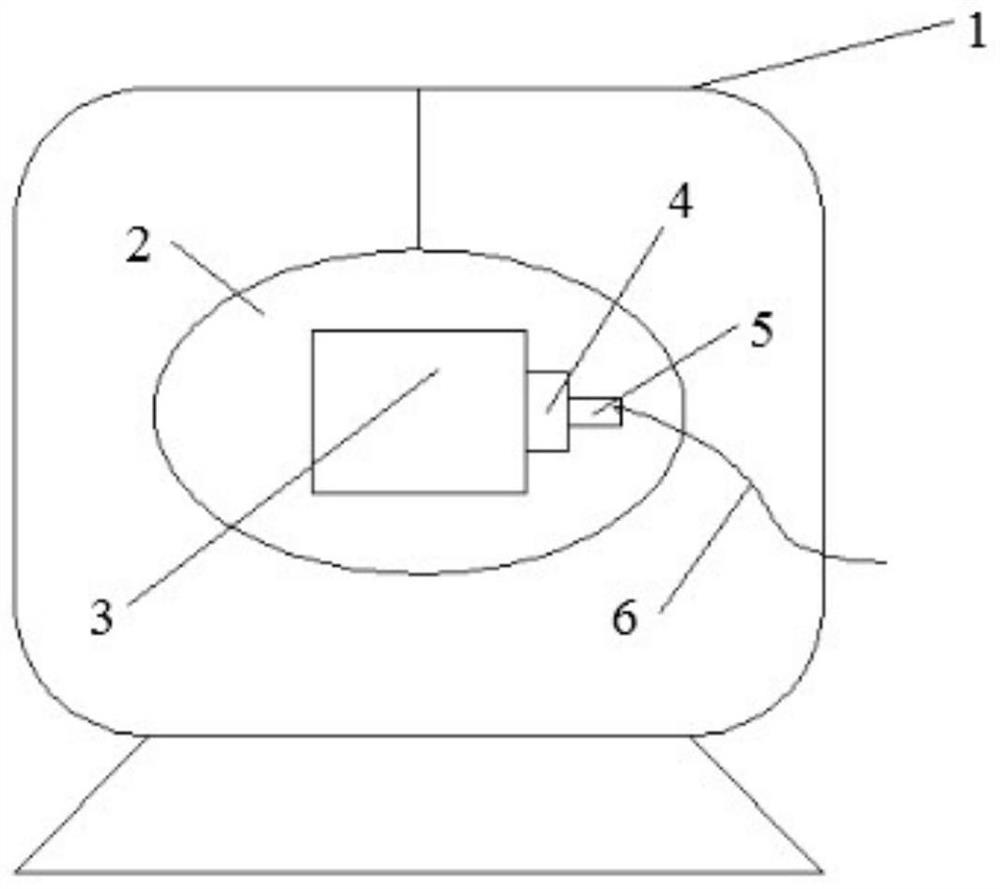

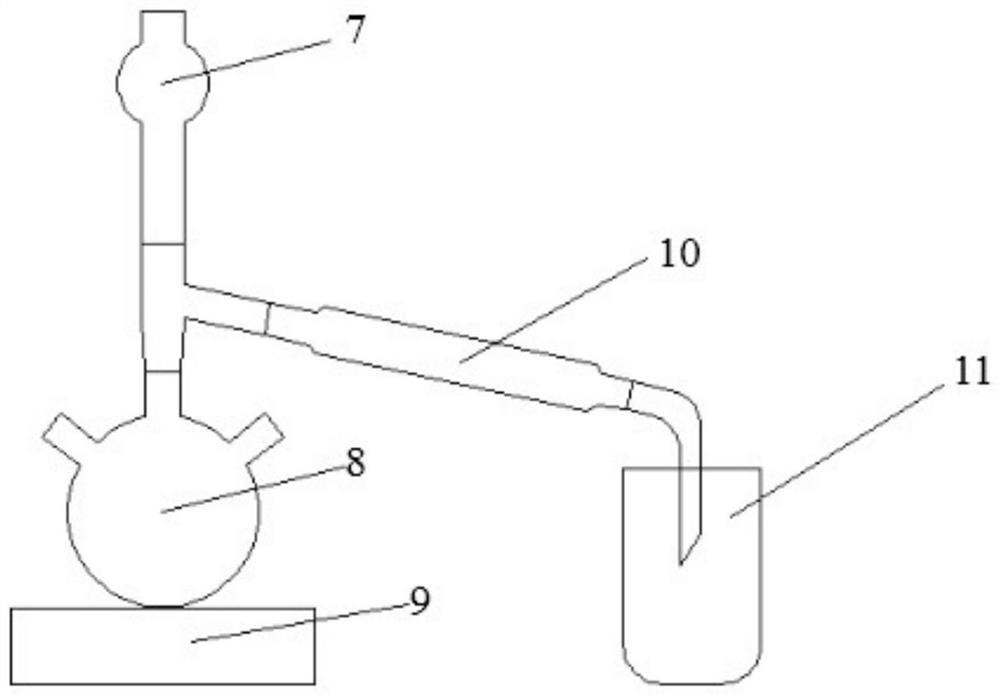

Image

Examples

Embodiment 1

[0046] 1. Detonation process

[0047] (1) Grain forming

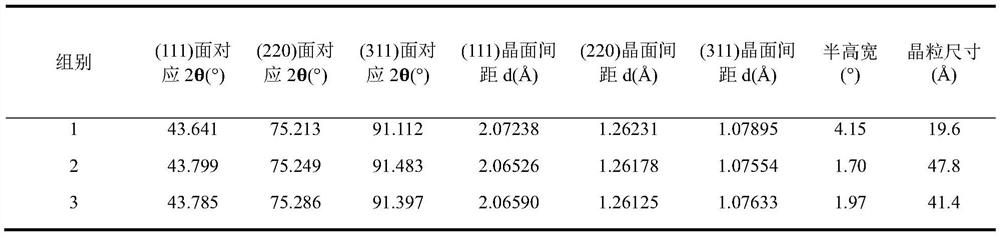

[0048] This invention uses the direct detonation method to synthesize polycrystalline diamond. There are three groups of experiments. The external carbon sources in each group are: graphite, retort cotton stalk, and retort sunflower stalk, numbered 1, 2, and 3 respectively, and the main drug column is pressed. The component ratio is 8701: external carbon source = 90: 10, and the main drug column size is The density of the main drug column is about 1.53g / cm 3 . Dispensing according to the plan, weighing the carbon source and explosives of the corresponding quality, and mixing them evenly, using a hydraulic press for positioning and pressing to form the main drug column. At the same time, the pure 8701 explosive is used to position and press the booster column, and the size of the booster column is The density of the explosive column is about 1.50g / cm 3 .

[0049] (2) Detonation

[0050]In order to successfully d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com