A high-performance die-casting forming method and product based on a two-plate die-casting machine

A die-casting, high-performance technology, applied in the field of metal parts manufacturing and processing, can solve the problems of lack of die-casting technology, unsuitable two-plate die-casting machine, etc., and achieve the effects of eliminating heat treatment defects, good sealing, and increasing booster specific pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this embodiment, a kind of ADC12 aluminum alloy automobile structure is die-cast. A series of preparations are carried out before die-casting, including two-plate die-casting machine equipment inspection, mold preheating (preheating temperature is 200°C), spraying a layer of release agent on the surface of the die-casting mold, aluminum alloy melting, aluminum liquid transportation, etc.

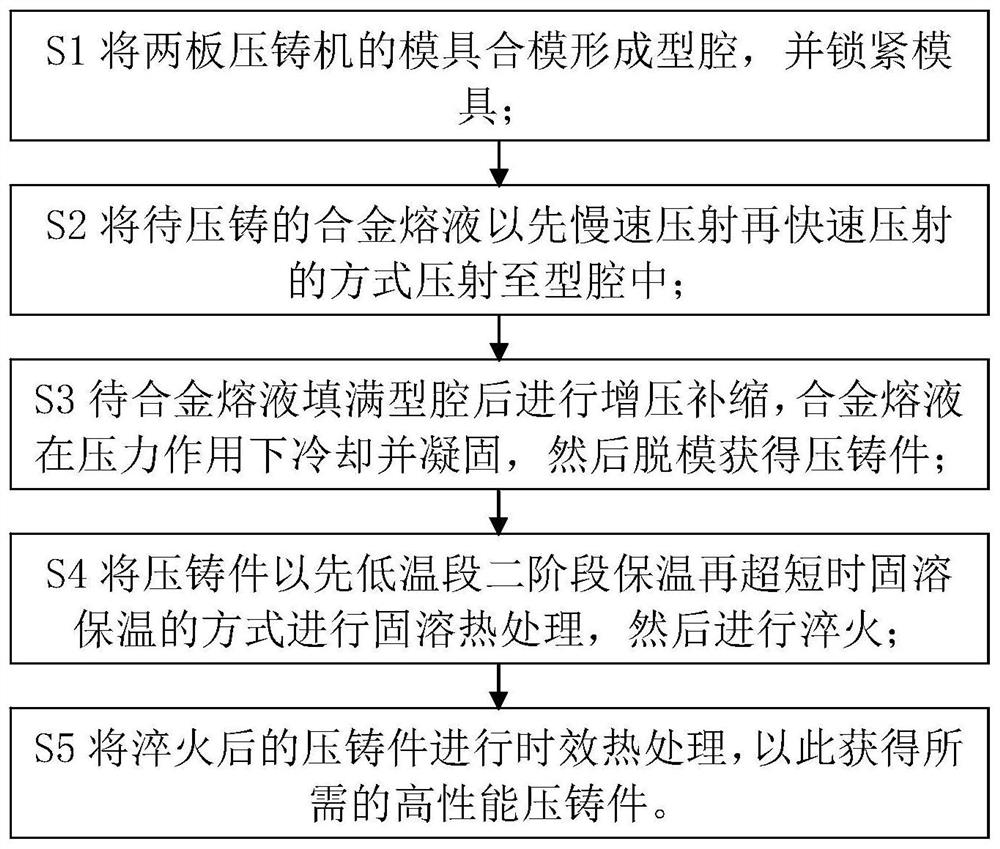

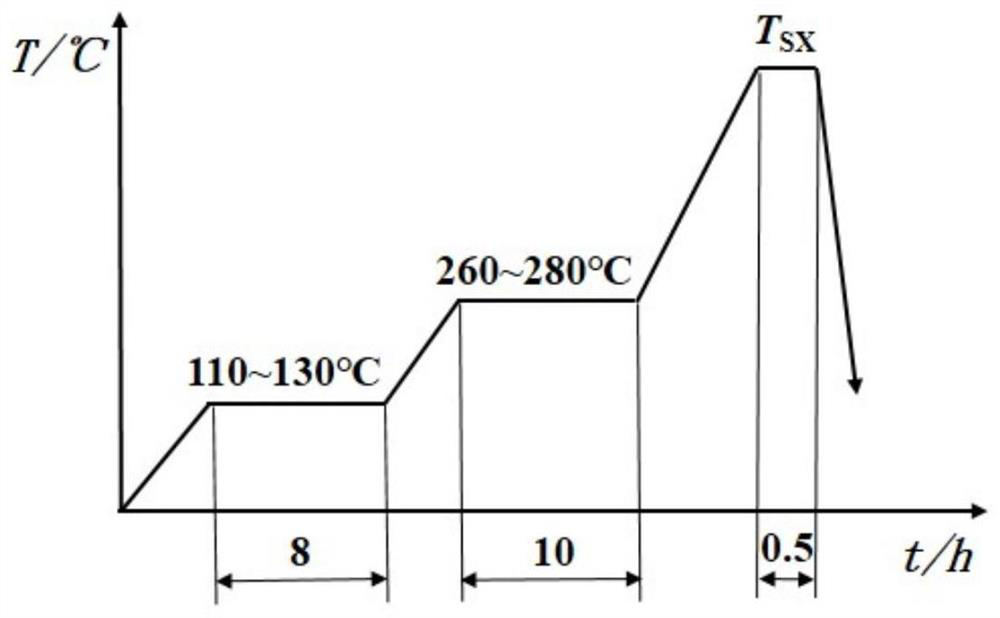

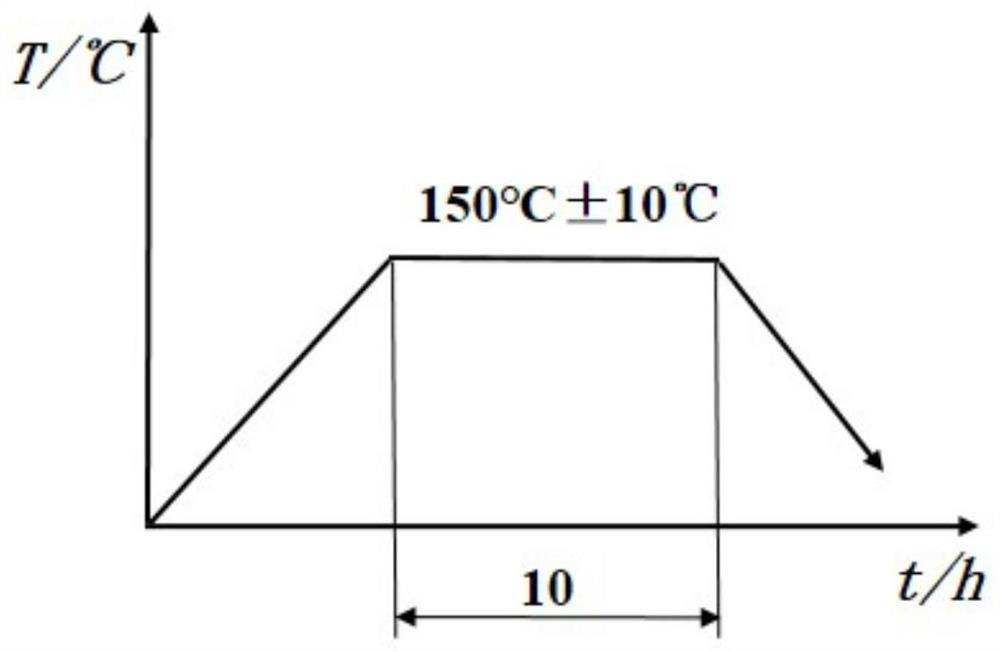

[0053] A die casting cycle and heat treatment process specifically includes the following steps:

[0054] Mold clamping and locking: contact the movable mold with the fixed mold to form a mold cavity, and use the follow-up locking mechanism of the two-plate die-casting machine to lock the mold;

[0055] Pouring and injection: Pour 680°C aluminum alloy melt into the barrel of the die-casting machine, and then use the punch to inject the aluminum hydraulic pressure into the mold cavity that has been preheated to 200°C. The injection process is as follows: It is slow injection, and t...

Embodiment 2

[0061] In this embodiment, a YL112 brand aluminum alloy automobile structural part is die-cast. A series of preparations are carried out before die-casting, including two-plate die-casting machine equipment inspection, mold preheating (preheating temperature is 200°C), spraying a layer of release agent on the surface of the die-casting mold, aluminum alloy melting, aluminum liquid transportation, etc.

[0062] A die casting cycle and heat treatment process specifically includes the following steps:

[0063] Mold clamping and locking: contact the movable mold with the fixed mold, close the mold to form a cavity, and use the follow-up locking mechanism of the two-plate die-casting machine to lock the mold;

[0064] Pouring and injection: Pour 680°C aluminum alloy melt into the barrel of the die-casting machine, and then use the injection punch to inject the aluminum hydraulic pressure into the mold cavity that has been preheated to 200°C. The injection process is specific The f...

Embodiment 3

[0070]In this embodiment, a kind of ADC6 brand aluminum alloy automotive structural part is die-cast. A series of preparations are carried out before die-casting, including two-plate die-casting machine equipment inspection, mold preheating (preheating temperature is 200°C), spraying a layer of release agent on the surface of the die-casting mold, aluminum alloy melting, aluminum liquid transportation, etc.

[0071] A die casting cycle and heat treatment process specifically includes the following steps:

[0072] Mold clamping and locking: contact the movable mold with the fixed mold to form a mold cavity, and use the follow-up locking mechanism of the two-plate die-casting machine to lock the mold;

[0073] Pouring and injection: Pour 680°C aluminum alloy melt into the barrel of the die-casting machine, and then use the injection punch to inject the aluminum hydraulic pressure into the mold cavity that has been preheated to 200°C. The injection process is specific The first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com