New energy electric vehicle thermal management system with all-weather multi-mode switching function

A switching function, electric vehicle technology, applied in electric vehicles, air handling equipment, circuits, etc., can solve the problems of high temperature and uneven temperature of power battery packs, and achieve the effect of compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

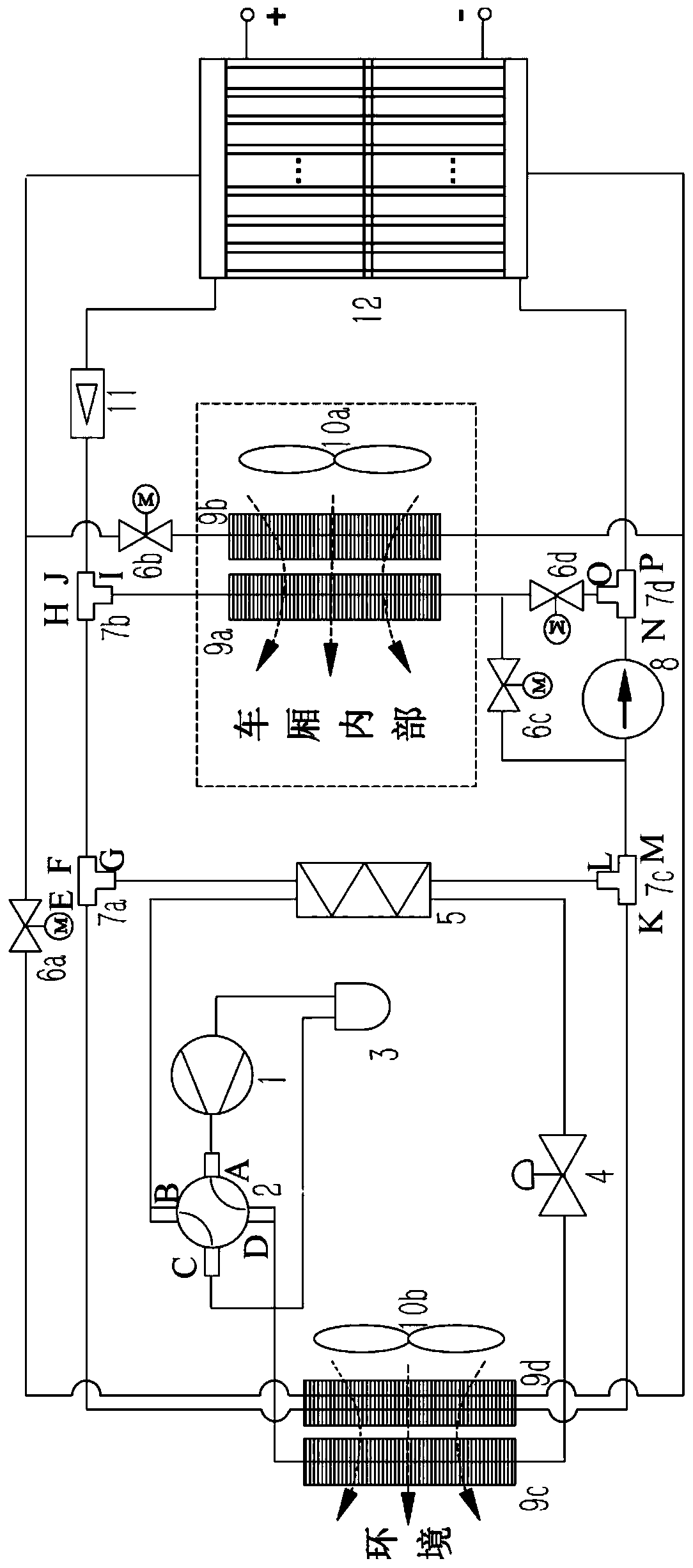

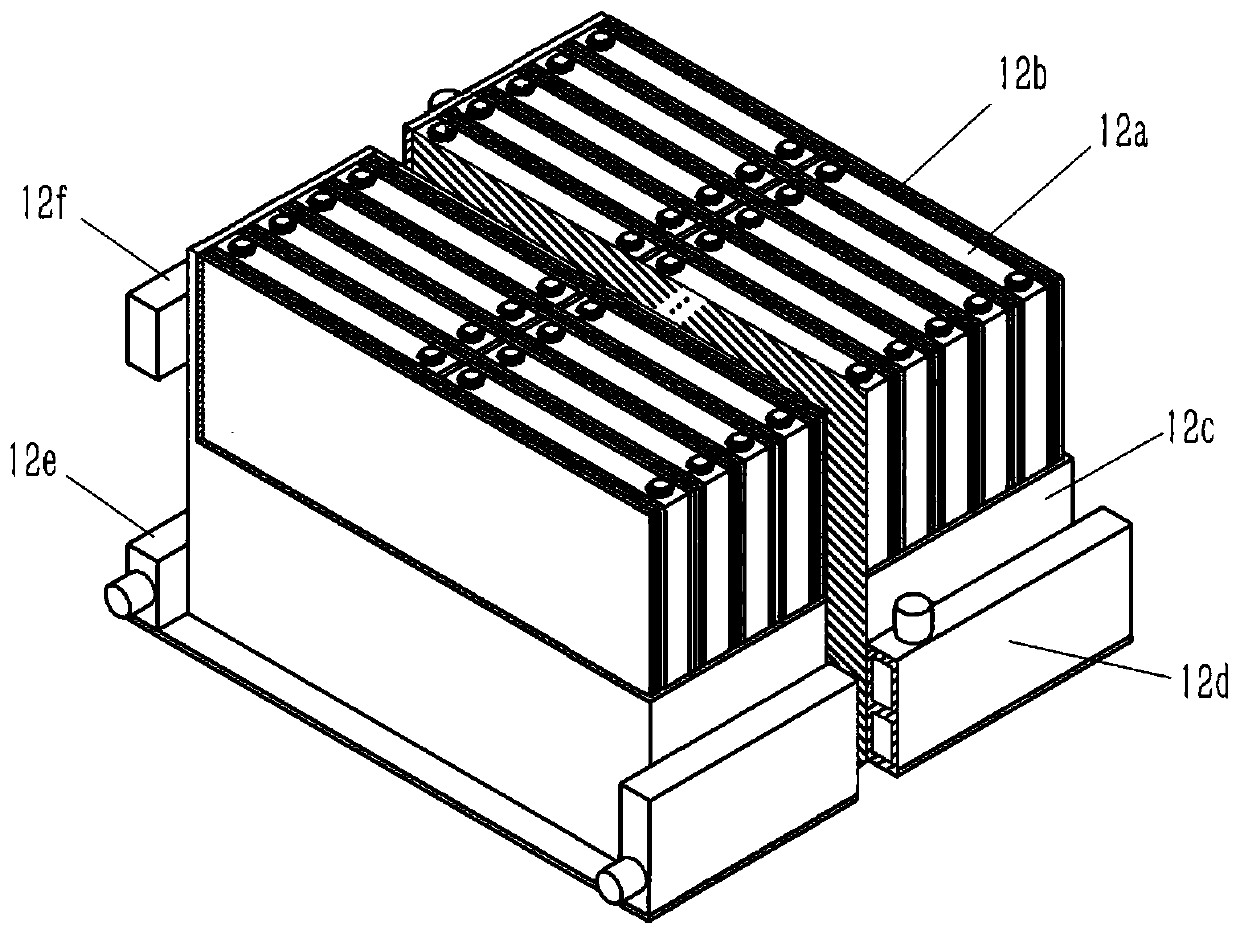

[0041] Such as figure 1 As shown, a new energy electric vehicle vehicle thermal management system with full climate multi-mode switching function includes a cooling / heating system with full climate multi-mode switching function and a battery pack 12;

[0042] The refrigeration / heating system includes an air compressor 1, a four-way reversing valve 2, a gas-liquid separator 3, an expansion valve 4, a heat exchanger 5, a circulating pump 8, a solenoid valve group, a three-way valve group, and fins The heat exchanger group and the flow meter 11, the solenoid valve group includes solenoid valve one 6a, solenoid valve two 6b, solenoid valve three 6c, and solenoid valve four 6d, and the three-way valve group includes three-way valve one 7a, three-way valve Valve two 7b, three-way valve three 7c and three-way valve four 7d, the fin heat exchanger group includes fin heat exchanger one 9a, fin heat exchanger two 9b, fin heat exchanger three 9c and fin The fin heat exchanger four 9d, the f...

Embodiment 2

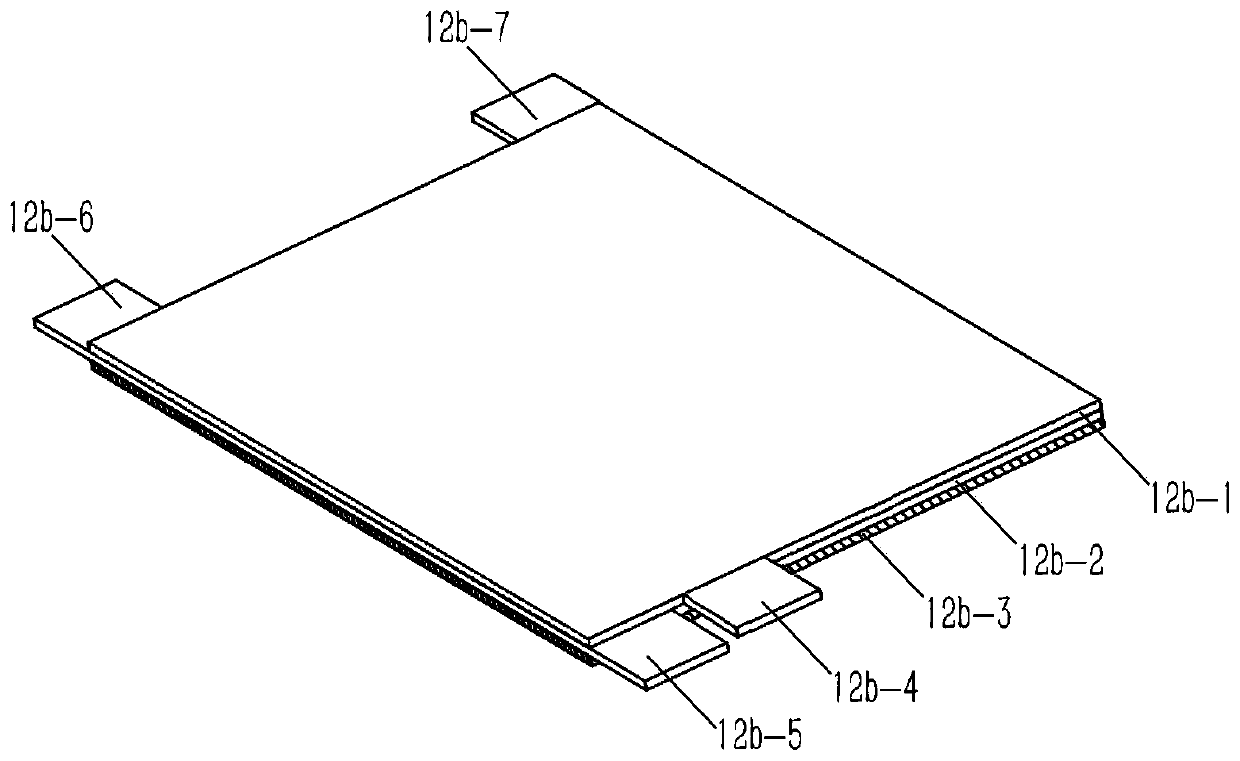

[0080] In this embodiment, the internal structure of the ultra-thin baffle 12b-2 is as Figure 7 As shown, the arrow in the figure indicates the direction of fluid flow. The ultra-thin baffle plate 12b-2 is provided with a number of baffle bars 12b-8 that are parallel to the overall flow direction of the fluid and are staggered to the left and right. Other embodiments Same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com