Preparation method of novel light bottom mud covering material and riverway bottom mud repairing method

A covering material and lightweight technology, applied in chemical instruments and methods, polluted waterways/lakes/ponds/rivers treatment, sludge treatment, etc., can solve the problem of anaerobic or facultative anaerobic environment, sediment High bearing capacity requirements, no functionality, etc., to achieve the effect of improving functionality and microbial activity, improving the acidic microenvironment of the sediment, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0036] Step 1: Disperse 100 parts of activated carbon in 200ml of water by ultrasonic, add 0.1g of hyperbranched polyethyleneimine,

[0037] Step 2: The activated carbon dispersion in step 1 is heated to 90°C by aeration and heating under the condition that the aeration rate is 15L / min; at the same time, 100ml of ferrous sulfate solution with a concentration of 0.1M and 100ml of sodium hydroxide solution with a concentration of 0.25M;

[0038] Step 3: The ferrous sulfate salt and the alkali solution are added dropwise synchronously, the constant temperature is 90°C, and the aeration rate is 15L / min for aeration and stirring for 3 minutes;

[0039] Step 4: magnetic separation, water washing to neutrality, and vacuum drying at 100° C. to constant weight to obtain a magnetic activated carbon adsorption material.

[0040] Manufacturing example of magnetic attapulgite clay adsorbent

[0041] Step 1: ultrasonically disperse 100 parts of attapulgite clay in 200ml of water, add 0.1g...

Embodiment 1-6

[0046] The preparation of the novel light-weight bottom mud covering material and its manufacturing method comprises the following steps:

[0047] (1) Fully stirring and mixing cement, hemihydrate gypsum, hydroxypropyl methylcellulose, magnetic activated carbon, magnetic attapulgite clay, polypropylene fiber, foamed polypropylene, and nano-titanium dioxide according to a certain proportion;

[0048](2) Water is added to the mixture in step (1), fully stirred, and granulated, with a particle size of 5-10 mm, and placed under normal temperature and pressure for natural curing for 3-7 days.

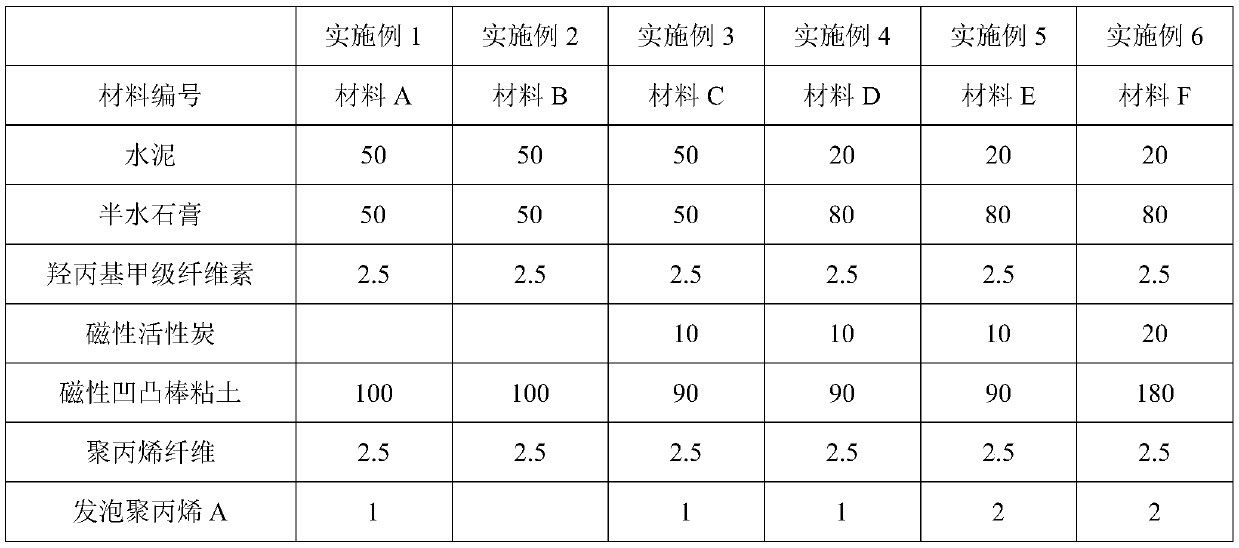

[0049] Materials A to F were prepared separately

[0050] The raw material parameters of the embodiment are shown in Table 1

[0051] Table 1

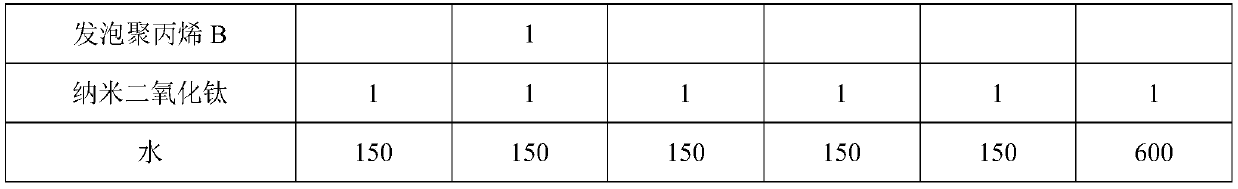

[0052]

[0053]

[0054] Remarks: Nano-titanium dioxide: formulated as a 10% suspension

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com