Preparation method of lightweight sediment cover material and river sediment restoration method

A covering material and sediment technology, applied in chemical instruments and methods, polluted waterways/lakes/ponds/rivers treatment, sludge treatment, etc. Facultative anaerobic environment and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0036] Step 1: Ultrasonic dispersion of 100 parts of activated carbon in 200 ml of water, adding 0.1 g of hyperbranched polyethyleneimine,

[0037] Step 2: The activated carbon dispersion in step 1 is aerated and heated to 90° C. under the condition of an aeration rate of 15 L / min; at the same time, 100 ml of ferrous sulfate solution with a concentration of 0.1 M and 100ml concentration is 0.25M sodium hydroxide solution;

[0038] Step 3: The ferrous sulfate salt and the alkali solution are added dropwise synchronously, and the temperature is kept at 90°C, and the aeration rate is 15L / min, aerated and stirred for 3 minutes;

[0039] Step 4: Magnetic separation, washing with water to neutrality, vacuum drying at 100° C. to constant weight, to prepare magnetic activated carbon adsorption material.

[0040] Manufacturing example of magnetic attapulgite clay adsorption material

[0041] Step 1: Ultrasonic dispersion of 100 parts of attapulgite clay in 200 ml of water, adding 0.1...

Embodiment 1-6

[0046] The preparation of the described lightweight sediment covering material and its manufacturing method comprises the following steps:

[0047] (1) Fully stir and mix cement, hemihydrate gypsum, hydroxypropyl methyl cellulose, magnetic activated carbon, magnetic attapulgite clay, polypropylene fiber, expanded polypropylene, and nano-titanium dioxide according to a certain proportion;

[0048] (2) Add water to the mixture in step (1), stir well and evenly, granulate, the particle size is 5-10mm, and place it under normal temperature and pressure for natural curing for 3-7 days.

[0049] Prepare materials A~F respectively

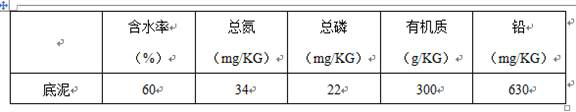

[0050] Each raw material parameter of embodiment is shown in Table 1

[0051] Table 1

[0052]

[0053] Remarks: Nano-titanium dioxide: prepared as a 10% suspension

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com