Preparation method for multicore-single shell microsphere sustained-release system with embedded GDNF

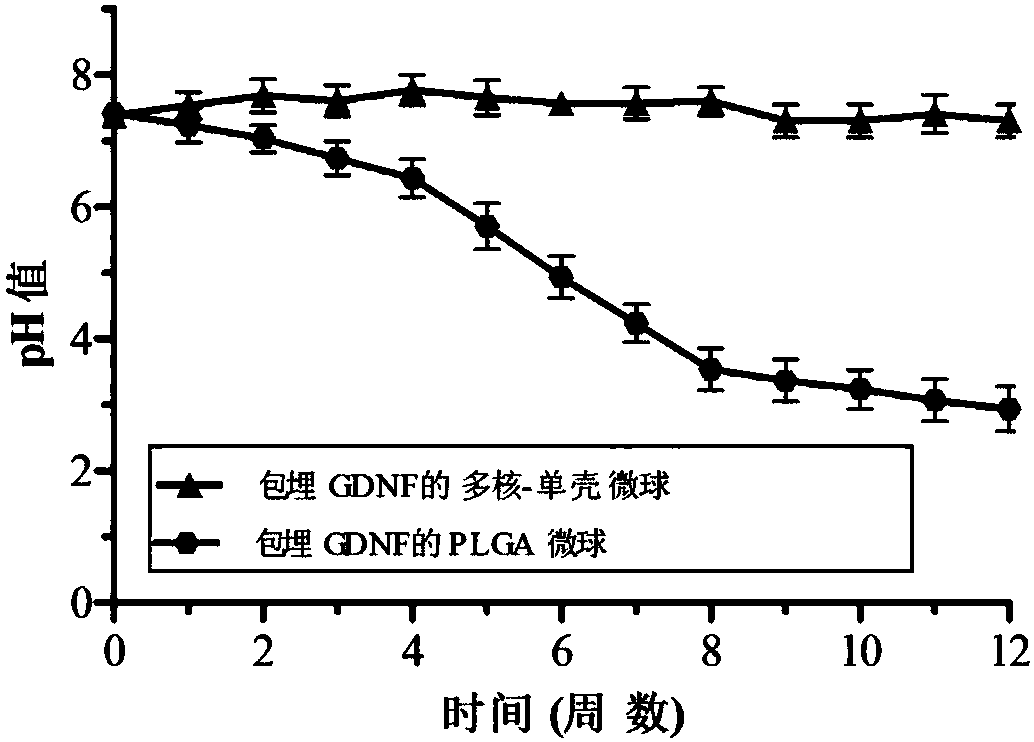

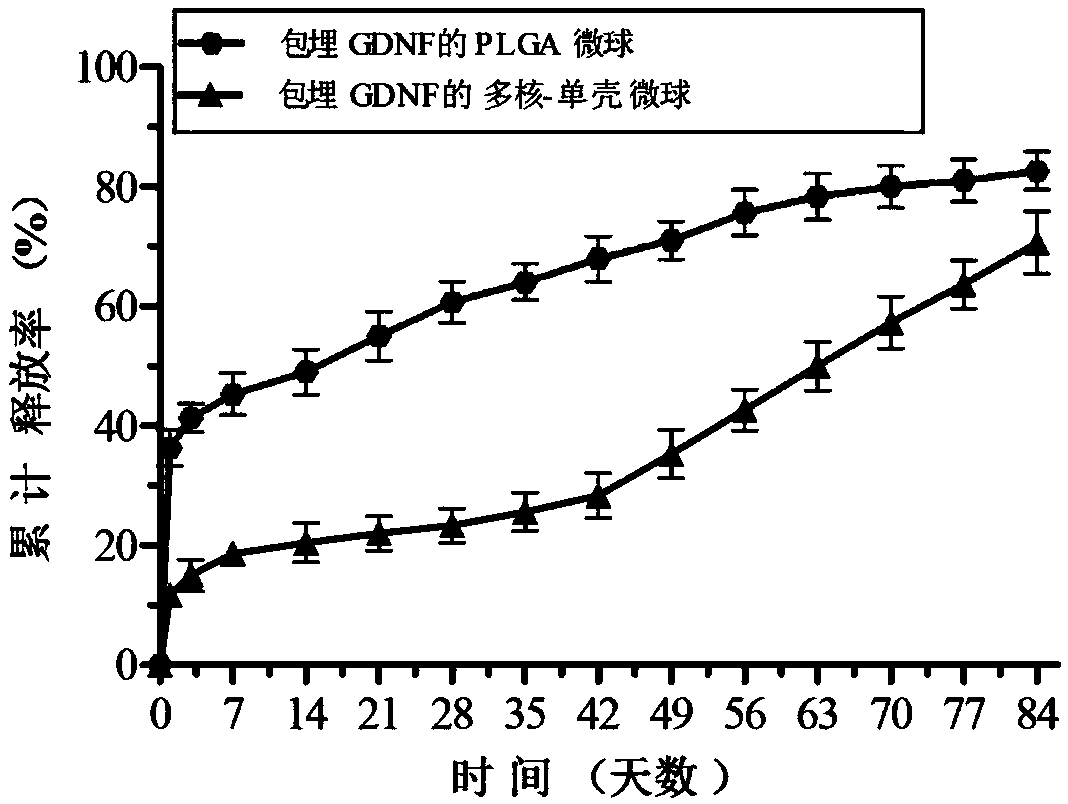

A microsphere and multi-core technology, applied in the direction of nervous system diseases, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problems of reducing the pH value of the surrounding microenvironment and limiting the regeneration of peripheral nerves, etc., to achieve Improve the effect of acidic microenvironment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

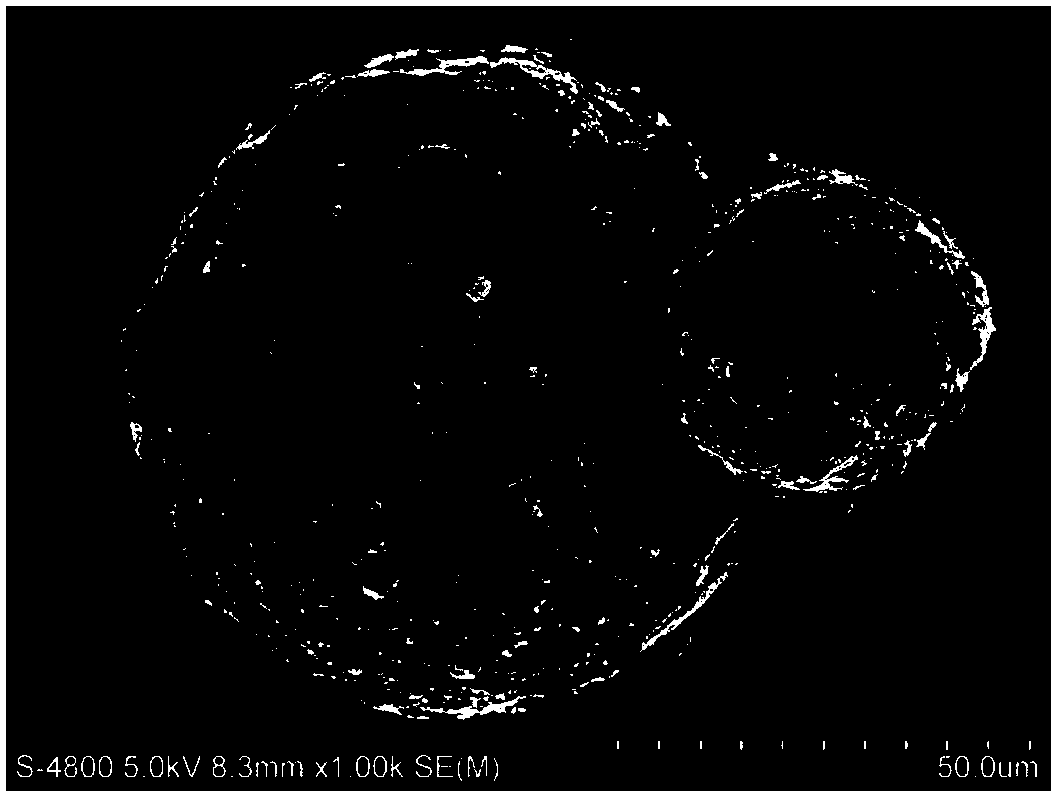

Embodiment 1

[0100] At 2°C, 60 μL LGDNF solution (0.1 mg / mL concentration), 100 mg docusate sodium and 7 mg human serum albumin were dissolved in 0.5 mL distilled water to prepare the inner aqueous phase W 1 ; 0.6g PLGA was dissolved in 6mL dichloromethane to prepare the oil phase O1 ; Mix 0.6mg polysorbate 80 with 60mL water evenly to prepare the outer layer of water phase W 2 ; the inner water phase W 1 Dispersed in the oil phase O 1 In the process, use an ultrasonic cell pulverizer to ultrasonically disperse for 10 s, and then pause for 10 s; repeat this process twice to obtain the primary emulsion W 1 / O 1 , the output power of the ultrasonic cell pulverizer is 100W, and the working frequency is 15kHz; the colostrum W 1 / O 1 Added to the outer aqueous phase W 2 In the process, the ultrasonic cell pulverizer was used to ultrasonically disperse for 10 s, and then paused for 10 s. This process was repeated twice to prepare a two-layer final emulsion W 1 / O 1 / W 2 , the output powe...

Embodiment 2

[0104] At 2°C, 70 μL LGDNF solution (0.1 mg / mL concentration), 105 mg docusate sodium and 7 mg human serum albumin were dissolved in 0.5 mL distilled water to prepare the inner aqueous phase W 1 ; 0.7g PLGA was dissolved in 6mL dichloromethane to prepare the oil phase O 1 ; Mix 0.6mg of polysorbate 80 with 62mL of water evenly to prepare the outer layer of water phase W 2 ; the inner water phase W 1 Dispersed in the oil phase O 1 In the process, use an ultrasonic cell pulverizer to ultrasonically disperse for 11s, and then pause for 11s; repeat this process twice to obtain the primary emulsion W 1 / O 1 , the output power of the ultrasonic cell pulverizer is 110W, and the working frequency is 16kHz; the colostrum W 1 / O 1 Added to the outer aqueous phase W 2 In the process, the ultrasonic cell pulverizer was used to ultrasonically disperse for 11s, and then paused for 11s. This process was repeated twice to prepare a two-layer final emulsion W 1 / O 1 / W 2 , the output ...

Embodiment 3

[0108] At 3°C, 80 μL LGDNF solution (0.1 mg / mL concentration), 110 mg docusate sodium and 7.5 mg human serum albumin were dissolved in 0.5 mL distilled water to prepare the inner aqueous phase W 1 ; 0.8g PLGA was dissolved in 6mL dichloromethane to prepare the oil phase O 1 ; Mix 0.6mg of polysorbate 80 with 65mL of water evenly to prepare the outer layer of water phase W 2 ; the inner water phase W 1 Dispersed in the oil phase O 1 In the process, use an ultrasonic cell pulverizer to ultrasonically disperse for 13s, and then pause for 13s; repeat this process twice to obtain the primary emulsion W 1 / O 1 , the output power of the ultrasonic cell pulverizer is 130W, and the working frequency is 18kHz; the colostrum W 1 / O 1 Added to the outer aqueous phase W 2 In the process, the ultrasonic cell pulverizer was used to ultrasonically disperse for 13s, and then paused for 13s. This process was repeated twice to prepare a two-layer final emulsion W 1 / O 1 / W 2 , the outpu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com