Tannic acid modified polyethyleneimine compound, preparation method thereof and gene vector

A polyethylenimine and tannic acid technology, applied in the field of biomedicine, can solve the problems of restricting the development and application of gene carriers, unsatisfactory cytotoxicity, complex synthesis steps, etc., and achieves reduced synthesis cost, low toxicity, and fewer synthesis steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

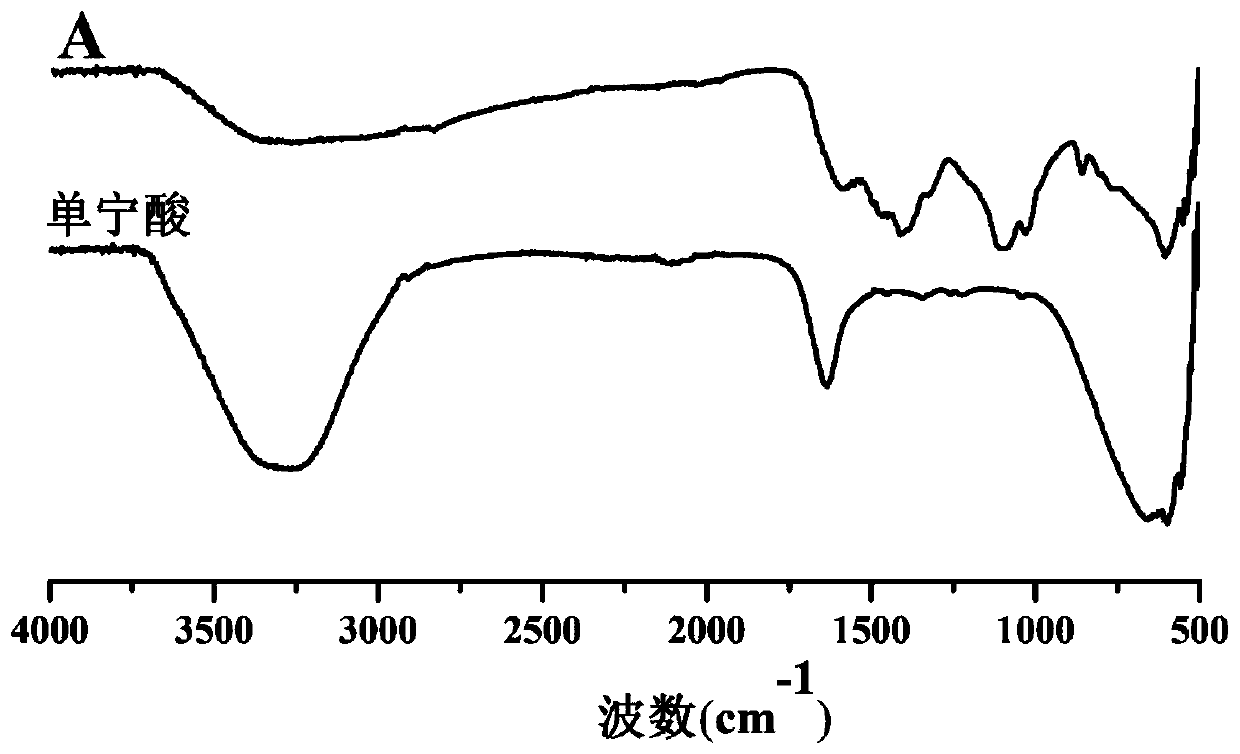

[0053] In the present embodiment, the preparation method of the tannic acid modified polyethyleneimine compound comprises the following steps:

[0054] Step S10, after mixing tannic acid, anhydrous tetrahydrofuran and triethylamine, adding chloroacetyl chloride, acetylation reaction to generate intermediate M;

[0055] Step S20, after mixing the intermediate M with anhydrous tetrahydrofuran, adding a tetrahydrofuran solution of polyethyleneimine, and stirring at 25-45°C to generate tannic acid-modified polyethyleneimine compound A;

[0056] Wherein, the intermediate M has the structure shown in the following structural formula (II):

[0057]

[0058] in,

[0059]

[0060] Its synthetic route is as follows:

[0061]

[0062] The method of the present invention uses tannic acid as a starting material, first prepares the intermediate M through chloroacetylation reaction, and then reacts the intermediate M with PEI to obtain a tannic acid-modified polyethyleneimine comp...

Embodiment 1

[0086] Add 2.0g of tannic acid, 25mL of anhydrous tetrahydrofuran, and 5mL of triethylamine into the round-bottomed flask in turn, and stir evenly. Under the condition of an ice-water bath, 28 mol of chloroacetyl chloride was slowly added dropwise to the above system. After the dropwise addition, the ice-water bath was removed, and the stirring reaction was continued at 35° C. for 20 h. The reaction system was transferred to a dialysis bag with a molecular weight cut-off of 2000, and dialyzed with running water for 24 hours, and then dialyzed with deionized water for 12 hours. During deionized water dialysis, the dialyzate was renewed every 2 hours. After the dialysis, the retentate was collected for low-temperature vacuum concentration, and then the concentrated product was pre-frozen at -20°C for 24 hours, and finally placed in a freeze dryer for 24 hours. , to obtain intermediate M.

[0087] Add 2.0 g of the above-obtained intermediate M and 25 mL of anhydrous tetrahydrofu...

Embodiment 2

[0090] Add 2.0g of tannic acid, 25mL of anhydrous tetrahydrofuran, and 5mL of triethylamine into the round-bottomed flask in turn, and stir evenly. Under the condition of ice-water bath, 28 mol of chloroacetyl chloride was slowly added dropwise to the above system. After the dropwise addition, the ice-water bath was removed, and the stirring reaction was continued at 25° C. for 24 h. The reaction system was transferred to a dialysis bag with a molecular weight cut-off of 2000, and dialyzed with running water for 24 hours, and then dialyzed with deionized water for 12 hours. During deionized water dialysis, the dialyzate was updated every 2 hours. After the dialysis, the retentate was collected for low-temperature vacuum concentration, and then the concentrated product was pre-frozen at -18°C for 26 hours, and finally placed in a freeze dryer for 24 hours. , to obtain intermediate M.

[0091] Add 2.0 g of the above-obtained intermediate M and 25 mL of anhydrous tetrahydrofuran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com