Biodegradable green printing ink binder, ink and preparation method of ink

A printing ink and biodegradation technology, applied in the field of ink additives, can solve the problems of difficult biodegradation, secondary pollution, health hazards of operators, etc., and achieve the effect of reducing pollution and improving environmental performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

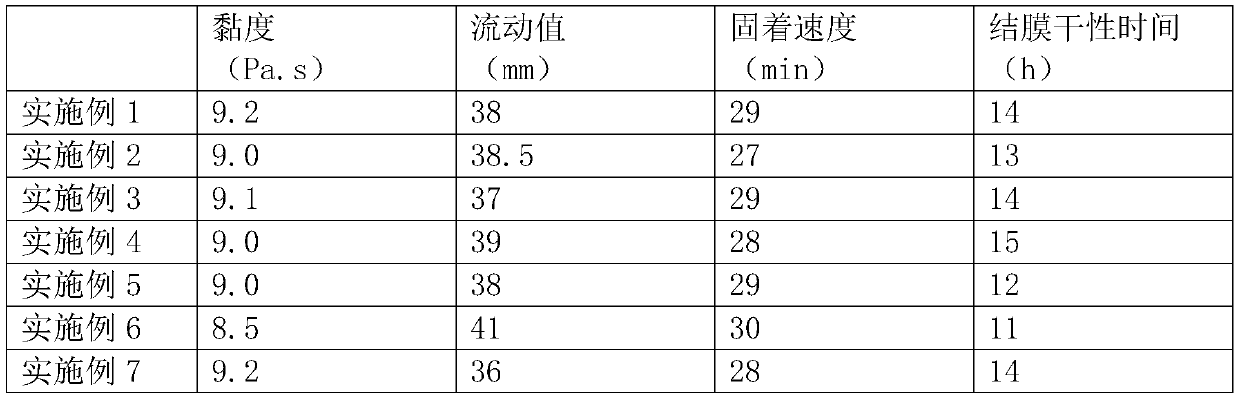

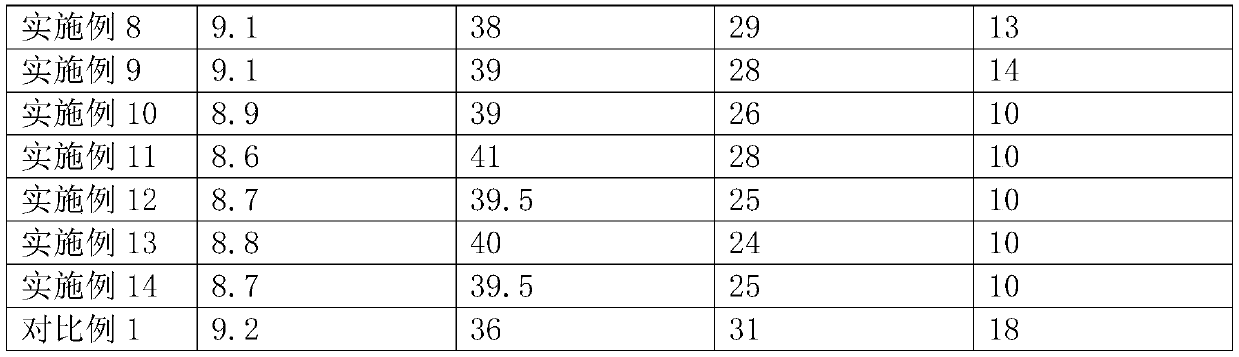

Examples

Embodiment 1

[0046] A biodegradable green printing ink binder disclosed by the invention comprises the following components in parts by weight,

[0047] Vegetable oil: 5 parts soybean oil, 1 part isooctyl palmitate, 4 parts palm oil, 3 parts linseed oil, 3 parts tung oil;

[0048] Resin: 20 parts of modified phenolic resin, 10 parts of dry long oil alkyd resin;

[0049] Excipients: 0.5 part of aluminum gel, 0.1 part of antioxidant.

[0050] Among them, the modified phenolic resin is a rosin-modified diphenol-based propane resin; the dry long-oil alkyd resin is JC115 long-oil alkyd resin.

[0051] A preparation method of biodegradable green printing ink binder, comprising the steps of:

[0052] S1: Take various raw materials according to the proportion of parts by weight, mix the vegetable oil evenly, and mix the resin evenly;

[0053] S2: Add a catalyst to the mixed vegetable oil, the catalyst is anthraquinone, the catalyst is 2-6% by weight of the vegetable oil, stir evenly, and at the...

Embodiment 2

[0058] The difference with Example 1 is:

[0059] A kind of biodegradable green printing ink binder, by weight, comprises the following components,

[0060] Vegetable oil: 7 parts of soybean oil, 2.8 parts of isooctyl palmitate, 6.3 parts of palm oil, 5.6 parts of linseed oil, and 5.6 parts of tung oil;

[0061] Resin: 23 parts of modified phenolic resin, 13.8 parts of dry long oil alkyd resin;

[0062] Excipients: 0.8 part of aluminum gel, 0.5 part of antioxidant.

[0063] Wherein, the modified phenolic resin is a rosin-modified diphenol-based propane resin and a rosin-modified p-tert-butylphenolic resin in parts by weight of 1:1.

[0064] At this time, the ratio of modified phenolic resin to dry long oil alkyd resin is 1:0.6.

[0065] The ratio of soybean oil, isooctyl palmitate and palm oil is 1:0.4:0.9.

[0066] The ratio of soybean oil, linseed oil and tung oil is 1:0.8:0.8.

[0067] A preparation method of biodegradable green printing ink binder, comprising the step...

Embodiment 3

[0073] The difference with Example 1 is:

[0074] A kind of biodegradable green printing ink binder, by weight, comprises the following components,

[0075] Vegetable oil: 9 parts soybean oil, 3 parts isooctyl palmitate, 8 parts palm oil, 7 parts linseed oil, 7 parts tung oil;

[0076] Resin: 28 parts of modified phenolic resin, 18 parts of dry long oil alkyd resin;

[0077] Excipients: 2 parts of aluminum gel, 1 part of antioxidant.

[0078] Wherein, the modified phenolic resin is rosin modified p-tert-butylphenolic resin.

[0079] A preparation method of biodegradable green printing ink binder, comprising the steps of:

[0080] S1: Take various raw materials according to the proportion of parts by weight, mix the vegetable oil evenly, and mix the resin evenly;

[0081] S2: Add a catalyst to the mixed vegetable oil, the catalyst is anthraquinone, the catalyst is 6% by weight of the vegetable oil, stir evenly, and at the same time raise the temperature to 230°C, add the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com