Method for enriching and separating efficient phosphorus-accumulating bacteria in active sludge of biological membrane reactor

A biofilm reactor and activated sludge technology, applied in the direction of using microorganisms, separating microorganisms, etc., can solve the problems of heavy workload, long time consumption, and low proportion of phosphorus-accumulating bacteria, so as to reduce the interference of nutrient competition and improve Species richness, effects of increased exposure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Pretreatment of sludge:

[0048] Take 50mL of activated sludge from a biofilm reactor in good operating condition, vortex for 2min, centrifuge at 12000rpm for 30s, discard the supernatant, repeat twice, and then vortex for 2min for acclimatization and cultivation to ensure the separation of bacteria and sludge. full contact with

[0049] 2. In vitro acclimatization and enrichment of strains:

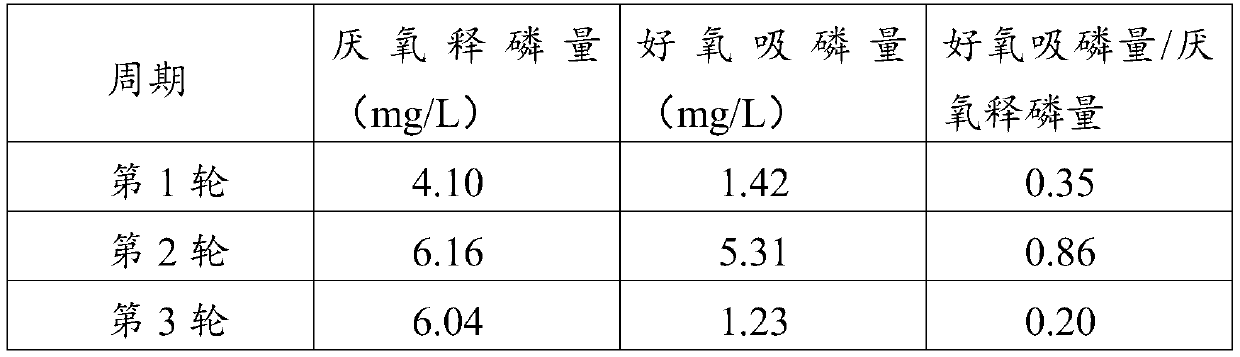

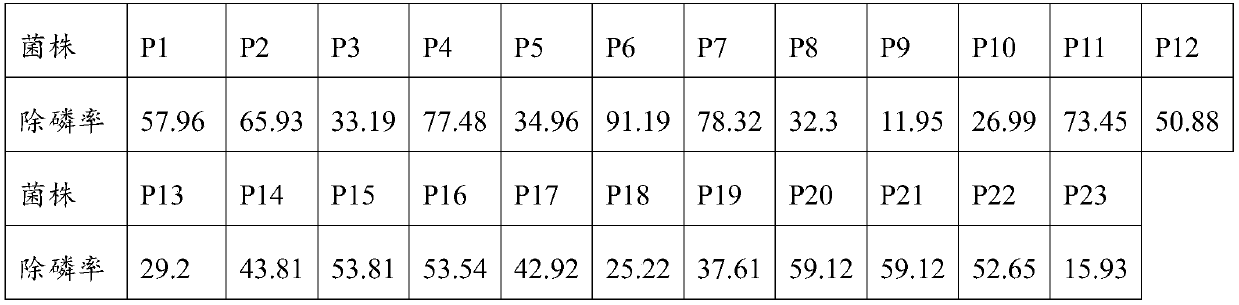

[0050]Pour the above sludge into a 250mL Erlenmeyer flask filled with 100mL anaerobic liquid medium, shake and mix well, fill it with nitrogen gas to reach anaerobic state, and let it stand at room temperature for 24h. Centrifuge the mixed liquid in the cone (6000rpm, 20min), discard the supernatant, pour the sludge sediment into the Erlenmeyer flask filled with aerobic liquid medium, seal it with a breathable filter membrane, shake it at room temperature for 23h (30±0.5 ℃, 150rpm), let stand for 1h. Repeat the above cycle of domestication and enrichment, while monitoring th...

Embodiment 2

[0081] 1. Pretreatment of sludge:

[0082] Take 50mL of biofilm reactor activated sludge in good operating condition;

[0083] 2. In vitro acclimatization and enrichment of strains:

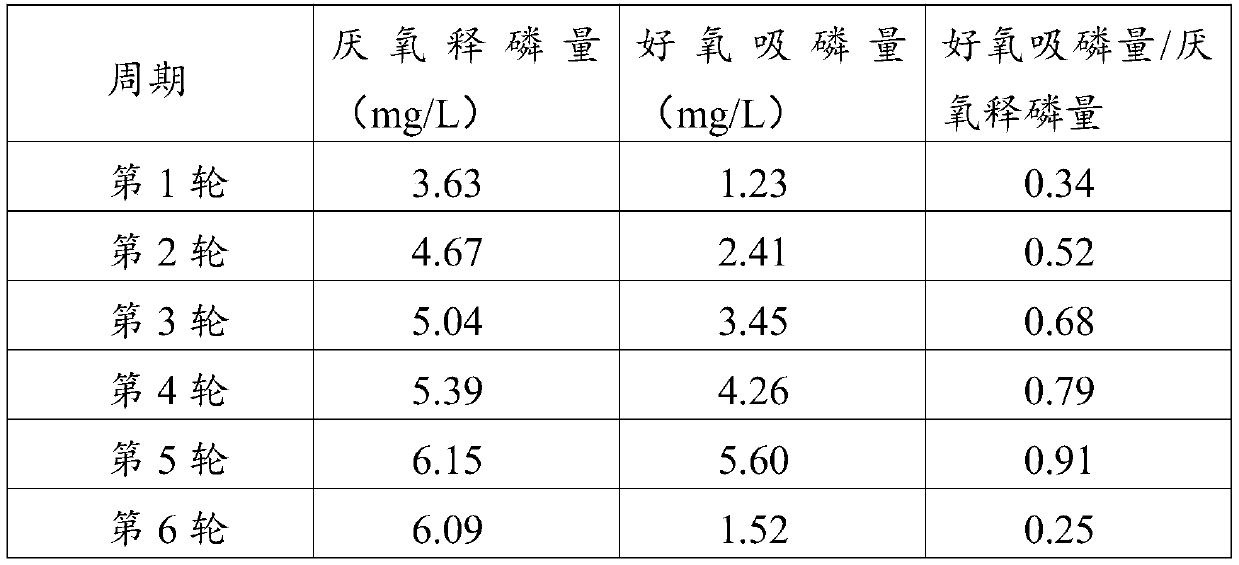

[0084] Pour the above sludge into a 250mL Erlenmeyer flask filled with 100mL anaerobic liquid medium, shake and mix well, fill it with nitrogen gas to reach anaerobic state, and let it stand at room temperature for 24h. Centrifuge the mixed liquid in the cone (6000rpm, 20min), discard the supernatant, pour the sludge sediment into the Erlenmeyer flask filled with aerobic liquid medium, seal it with a breathable filter membrane, shake it at room temperature for 23h (30±0.5 ℃, 150rpm), let stand for 1h. Repeat the above acclimatization and enrichment cycle while monitoring the phosphorus concentration in the supernatant. When the ratio of aerobic phosphorus uptake / anaerobic phosphorus release decreases, the cycle is stopped and separation is performed; Cycle domestication and enrichment, the rat...

Embodiment 3

[0112] 1. Pretreatment of sludge:

[0113] Take 50mL of activated sludge from a biofilm reactor in good operating condition, vortex for 3min, centrifuge at 12000rpm for 30s, discard the supernatant, repeat 3 times, and then vortex for 3min for acclimation and cultivation to ensure the separation of bacteria and sludge. full contact with

[0114] 2. In vitro acclimatization and enrichment of strains:

[0115] Pour the above sludge into a 250mL Erlenmeyer flask filled with 100mL anaerobic liquid medium, shake and mix well, fill it with nitrogen gas to reach anaerobic state, and let it stand at room temperature for 24h. Centrifuge the mixed liquid in the cone (6000rpm, 20min), discard the supernatant, pour the sludge sediment into the Erlenmeyer flask filled with aerobic liquid medium, seal it with a breathable filter membrane, shake it at room temperature for 23h (30±0.5 ℃, 150rpm), let stand for 1h. Repeat the above acclimatization and enrichment cycle while monitoring the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com